English (GB)

29

10.2 Dismantling the pump

10.2.1 Oil change

After 3000 operating hours or once a year, change

the oil in the oil chamber as described below.

If the shaft seal has been replaced, the oil must be

changed.

Draining of oil

1. Place the pump on a plane surface with one oil

screw pointing downwards.

2. Place a suitable container (approximately 1 litre),

for instance made of transparent plastic material,

under the oil screw.

3. Remove the lower oil screw.

4. Remove the upper oil screw.

If the pump has been in operation for a long

period of time, if the oil is drained off shortly after

the pump has been stopped, and if the oil is

greyish white like milk, it contains water. If the oil

contains more than 20 % water, it is an indication

that the shaft seal is defective and must be

replaced. If the shaft seal is not replaced, the

motor will be damaged.

If the quantity of oil is smaller than the quantity

stated in section 10.4 Oil quantities, the shaft

seal is defective.

5. Clean the faces for the gaskets for oil screws.

Filling with oil

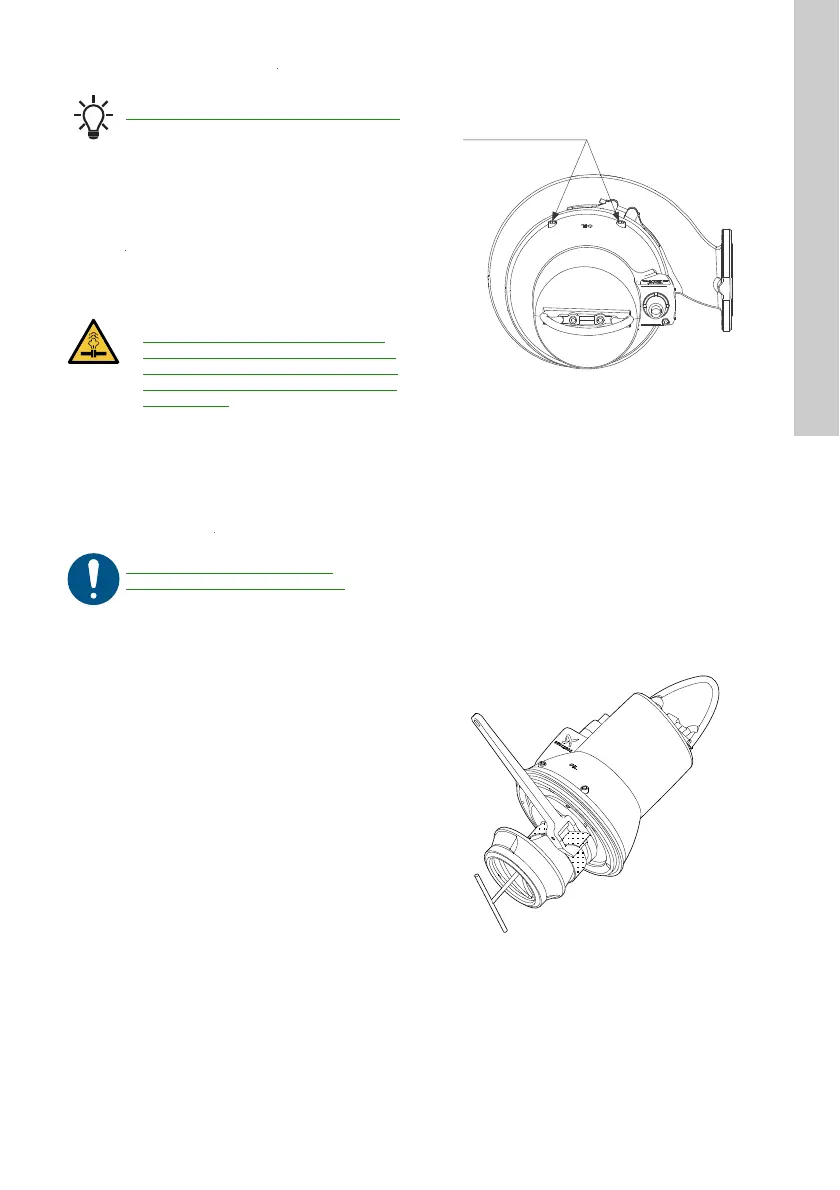

1. Turn the pump so that the oil filling holes are

placed opposite to each other, pointing upwards.

Fig. 16 Oil filling holes

2. Pour oil into the chamber.

For oil quantity, see section 10.4 Oil quantities.

3. Fit the oil screws with new gaskets.

10.2.2 Removing the pump housing and impeller

For position numbers, see pages 884 and 885.

Procedure

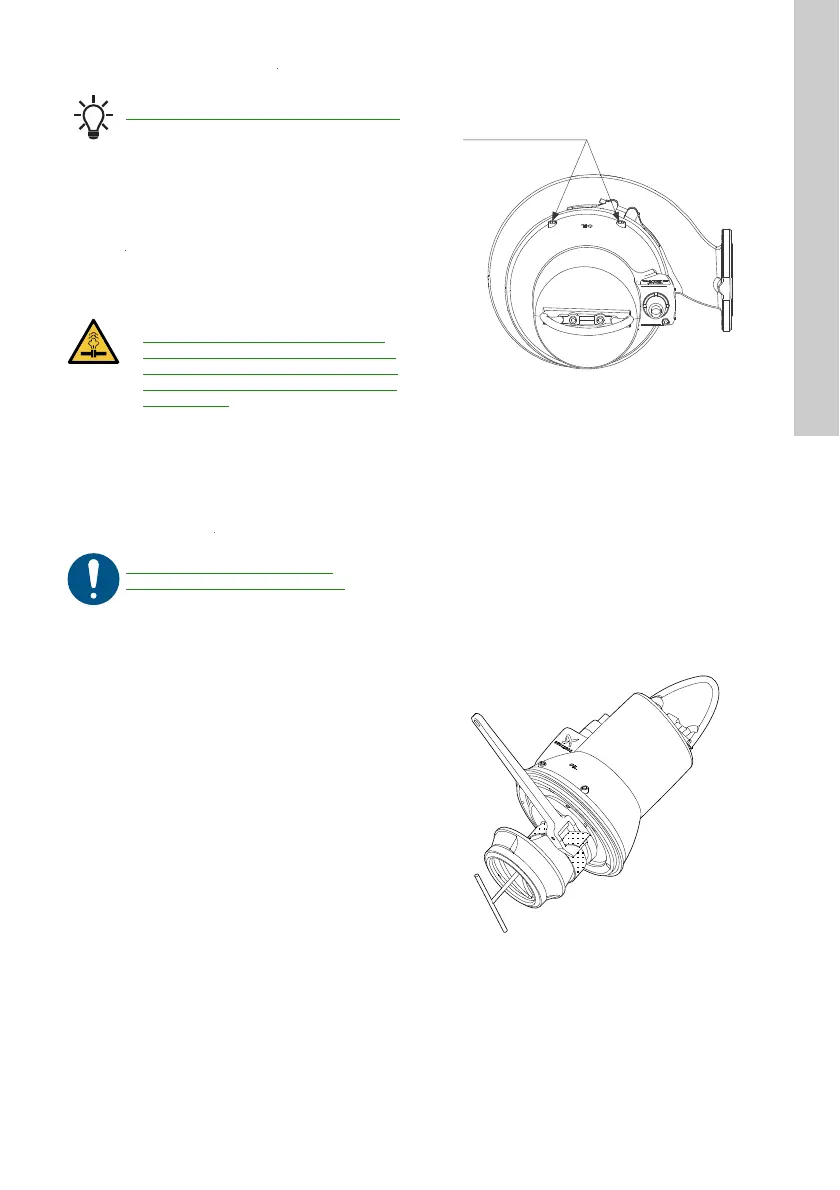

1. Loosen the clamp (92).

2. Remove the screw (92a) using your fingers.

3. Remove the pump housing (50) by inserting two

screwdrivers between the cooling jacket and the

pump housing.

4. Remove the screw (188a). Hold the impeller with

a strap wrench.

Fig. 17 Removing the impeller

5. Loosen the impeller (49) with a light blow on the

edge. Pull it off.

6. Remove the key (9a) and the spring for impeller

(157).

See www.grundfos.com for service videos.

CAUTION

Pressurised system

Minor or moderate personal injury

- When loosening the screws of the oil

chamber, note that pressure may have

built up in the chamber. Do not remove

the screws until the pressure has been

fully relieved.

Used oil must be disposed of in

accordance with local regulations.

TM04 6477 0410TM04 6476 0410

Loading...

Loading...