English (GB)

25

9. Startup

9.1 General startup procedure

This procedure applies to new installations as well

as after service inspections if startup takes place

some time after the pump was placed in the tank.

1. Remove the fuses and check that the impeller

can rotate freely. Turn the impeller by hand.

2. Check the condition of the oil in the oil chamber.

See also section 10.1 Inspection.

3. Check that the system, bolts, gaskets, pipes and

valves are in correct condition.

4. Mount the pump in the system.

5. Switch on the power supply.

6. Check whether the monitoring units, if used, are

operating satisfactorily.

7. For pumps with WIO sensor, switch on IO 113

and check that there are no alarms or warnings.

See section 8.6 IO 113.

8. Check the setting of air bells, float switches or

electrodes.

9. Check the direction of rotation. See section

9.3 Direction of rotation.

10. Open the isolating valves, if fitted.

11. Check that the liquid level is above the motor for

S1 operation and above the cable entry for S3

operation. See fig. 14. If the minimum level is not

reached do not start the pump.

12. Start the pump and let the pump run briefly, and

check if the liquid level is falling.

13. Observe if the outlet pressure and input current

are normal. If not there might be air trapped

inside the pump.

After one week of operation or after replacement of

the shaft seal, check the condition of the oil in the

chamber. For pumps without sensor, this is done by

taking a sample of the oil. See section

10. Maintenance and service for procedure.

Every time the pump has been removed from the

tank, go through the above procedure when starting

up again.

9.2 Operating modes

The pumps are designed for intermittent operation

(S3). When completely submerged, the pumps can

also operate continuously (S1).

S3, intermittent operation:

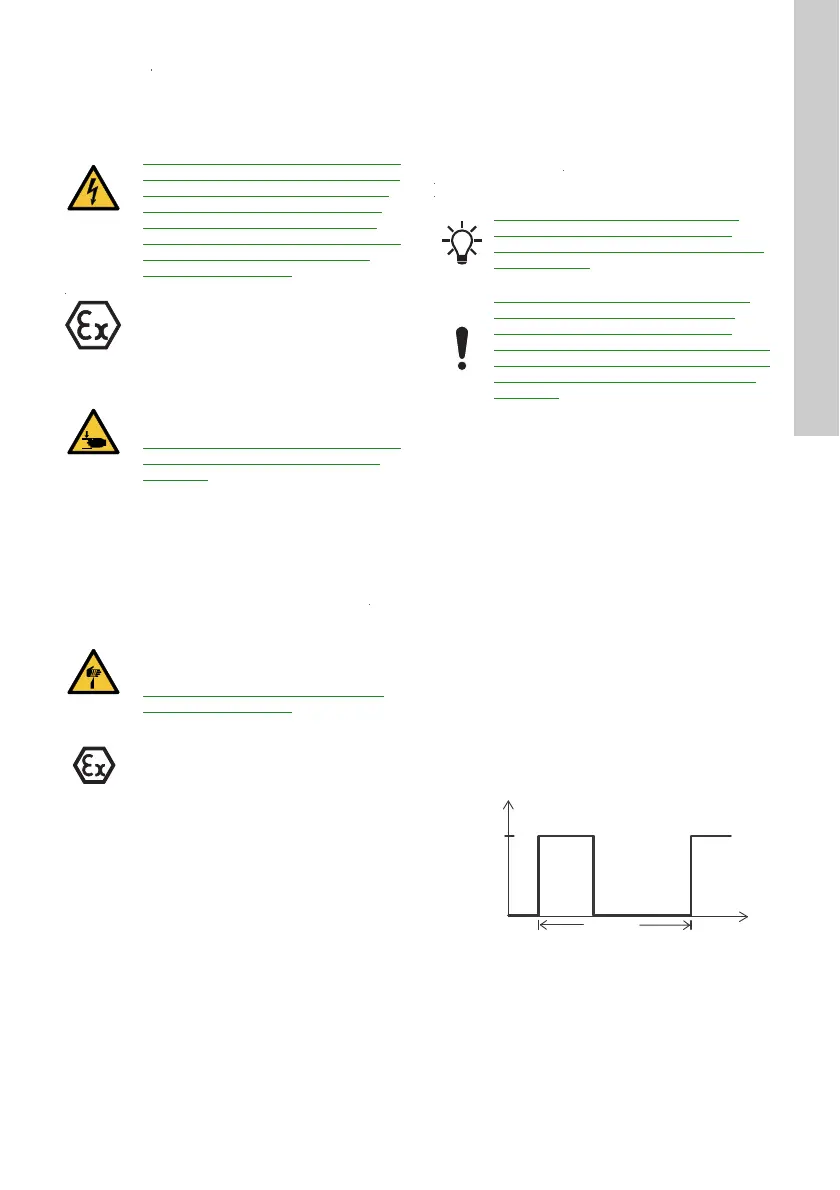

Operating mode S3 means that within 10 minutes the

pump must be in operation for 4 minutes and

stopped for 6 minutes. See fig. 12.

In this operating mode, the pump is partly

submerged in the pumped liquid, that is the liquid

level reaches at minimum the top of the cable entry

on the motor housing. See fig. 2.

Fig. 12 S3, intermittent operation

DANGER

Electric shock

Death or serious personal injury

- Before starting work on the pump, make

sure that the fuses have been removed

or the main switch has been switched

off. Make sure that the power supply

cannot be accidentally switched on.

Make sure that all protective equipment

has been connected correctly. The

pump must not run dry.

The pump must not be started if the

atmosphere in the tank is potentially

explosive.

DANGER

Crushing of hands

Death or serious personal injury

- It may lead to personal injuries or death

to open the clamp while the pump is

operating.

CAUTION

Sharp element

Minor or moderate personal injury

- The impeller can have sharp edges -

wear protective gloves.

Check that there is positive inlet pressure

before starting up the pump.

Trapped air can be removed from the

pump housing by tilting the pump by

means of the lifting chain when the pump

is in operation.

In case of abnormal noise or vibrations

from the pump, other pump failure or

power supply failure or water supply

failure, stop the pump immediately. Do not

attempt to restart the pump until the cause

of the fault has been found and the fault

corrected.

TM04 4527 1509

Operation

Stop

6 min.4 min.

10 min.

P

t

Loading...

Loading...