11

Fig. 13

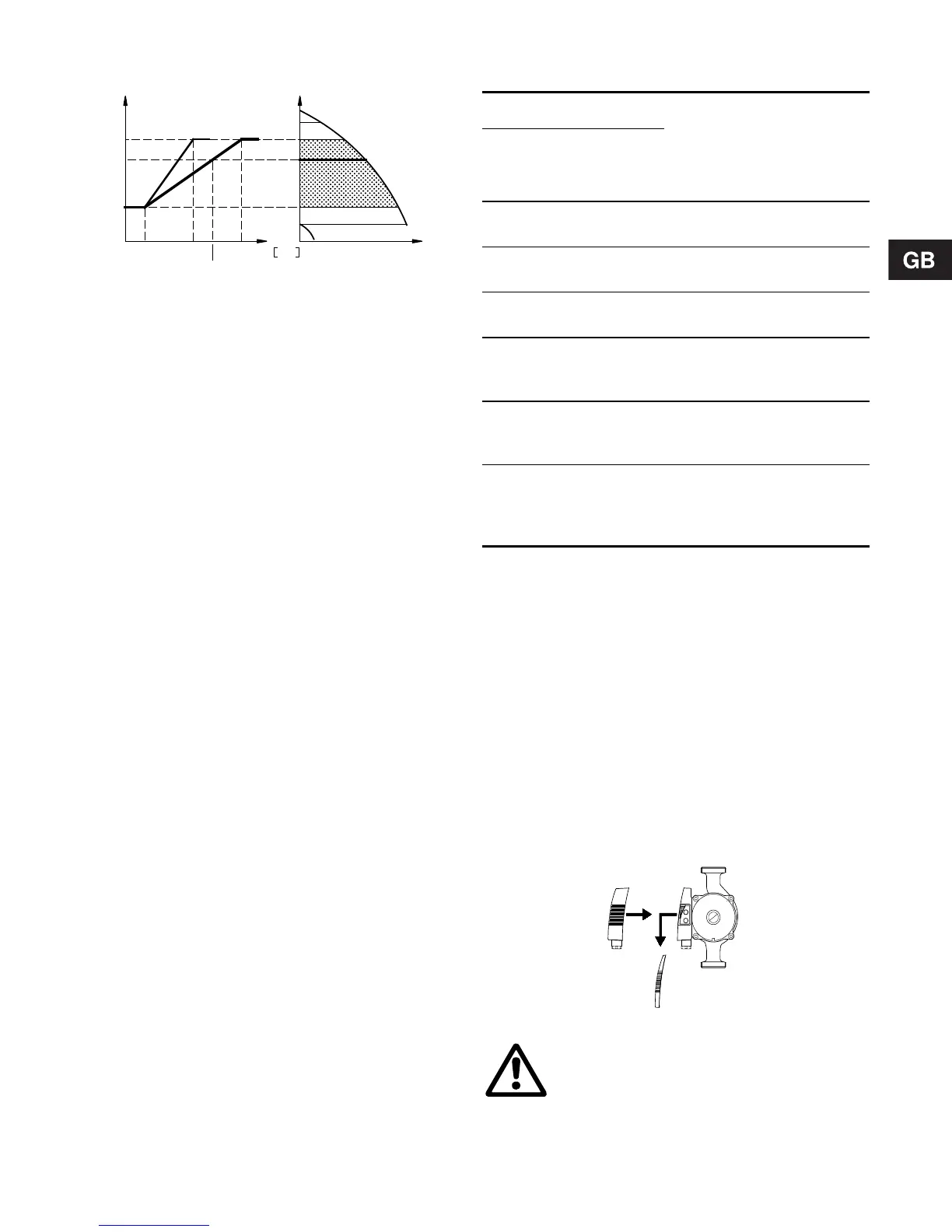

In the above example, T

max.

= 80°C has been se-

lected. The actual liquid temperature T

actual

causes

the setpoint for head to be reduced from 100% to

H

actual

.

The temperature influence function requires:

• Proportional or constant pressure control mode.

• The pump must be installed in the flow pipe.

• System with flow-pipe temperature control

(e.g. according to outdoor temperature).

Temperature influence is suitable in:

• systems with variable flows (e.g. two-pipe heating

systems), in which the activation of the tempera-

ture influence function will ensure a further reduc-

tion of the pump performance in periods with small

heating demands and consequently a reduced

flow-pipe temperature, and

• systems with almost constant flows (e.g. one-pipe

heating systems and underfloor heating systems),

in which variable heating demands cannot be reg-

istered as changes in the head (as is the case

with two-pipe heating systems). In such systems,

the pump performance can only be adjusted by

activating the temperature influence function.

Selection of T

max.

In systems with a dimensioned flow-pipe tempera-

ture of:

• up to and including 55°C, select T

max.

= 50°C,

• above 55°C, select T

max.

= 80°C.

Specifically for UPE 25-40, 25-40 A and 32-40:

In the temperature range of 20 to 30°C, the pump au-

tomatically changes over to operation according to

an uncontrolled night-time duty curve.

6.6 Indicator lights

The two indicator lights are used for fault and operat-

ing indication.

For position on pump, see fig. 21, section 7.2 Control

panel.

Note: When the R100 remote control communicates

with the pump, the red indicator light will flash rap-

idly.

Functions of indicator lights:

See also section 8. Fault finding chart.

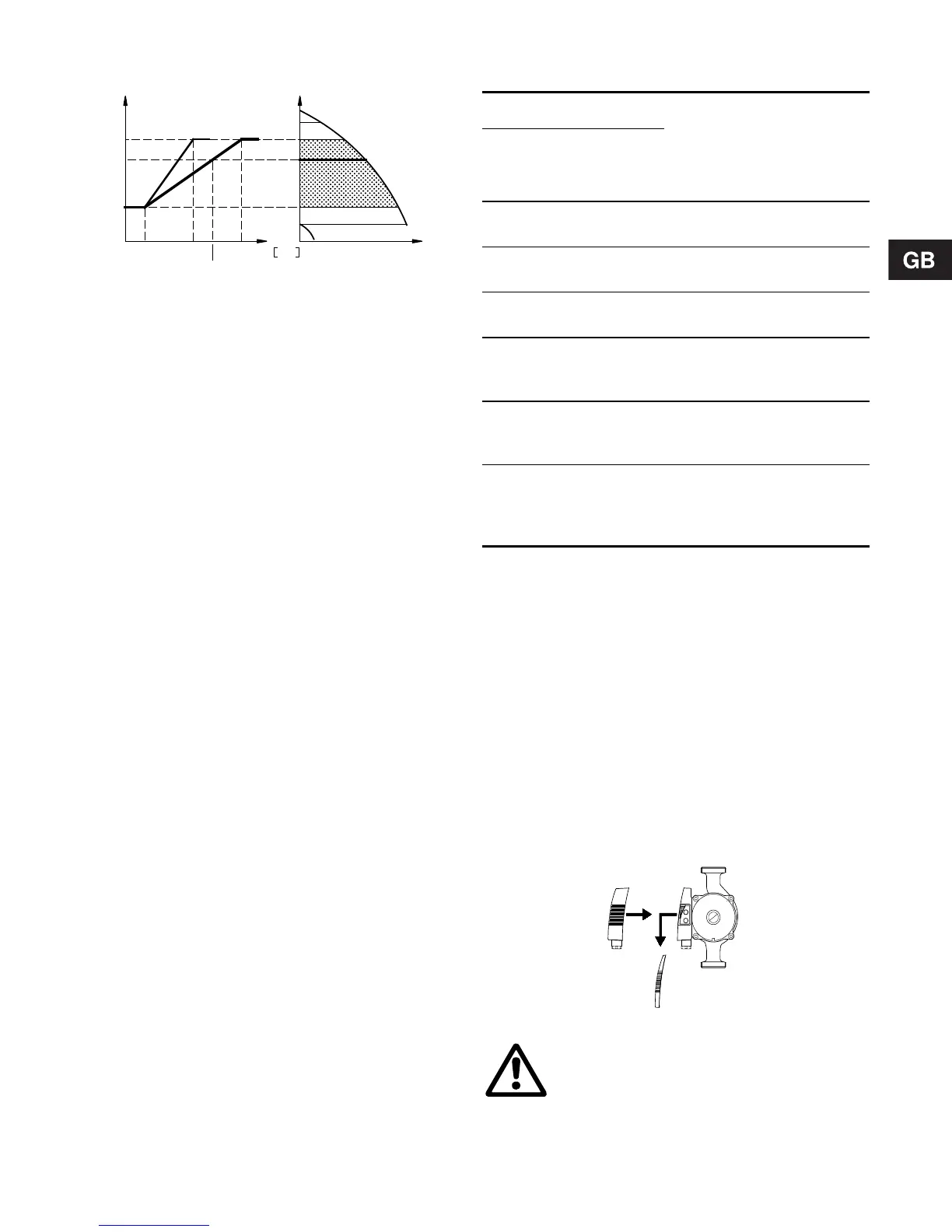

6.7 Expansion modules

The pump can be fitted with an expansion module

enabling communication with external signals (signal

transmitters).

Two types of expansion modules are available:

• Fault signal module, types MC 40/60 and MC 80.

• Bus module, types MB 40/60 and MB 80.

To fit a module, remove the existing terminal box

cover and fit the new cover incorporating the module.

The new cover increases the height of the terminal

box by approx. 20 mm, fig. 14.

Fig. 14

30%

100%

°CT

805020

H

H

Q

H

actual

T

actual

TM01 0626 1797

Indicator lights

Description Fault

(red)

Opera-

tion

(green)

Off Off

The electricity supply has

been switched off.

Off

Perma-

nently on

The pump is operating.

Off Flashing

The pump has been set

to stop.

Perma-

nently on

Off

The pump has stopped

because of a fault. Re-

starting will be attempted.

Perma-

nently on

Perma-

nently on

The pump is operating,

but it has been stopped

because of a fault.

Perma-

nently on

Flashing

The pump has been set

to stop, but it has been

stopped because of a

fault.

TM00 4463 3394

Never make any connections in the pump

terminal box unless the electricity supply

has been switched off for at least 5 min-

utes.

Loading...

Loading...