Operating

[

T-SELECTISETPOINT

1

I

SETPOINT: +040.00'C

I

SET-NEW +050.0WC

I

FUZZY

DENT

50.00°C

I

If the set temperature value is higher than 100°C the cool-

ing unit will not be switched on. Nevertheless, for special

applications, e.

g.

an expected exothermal reaction, it could

be suitable to let the cooling unit run (only partial cooling

capacity of

30%

of the full capacity).

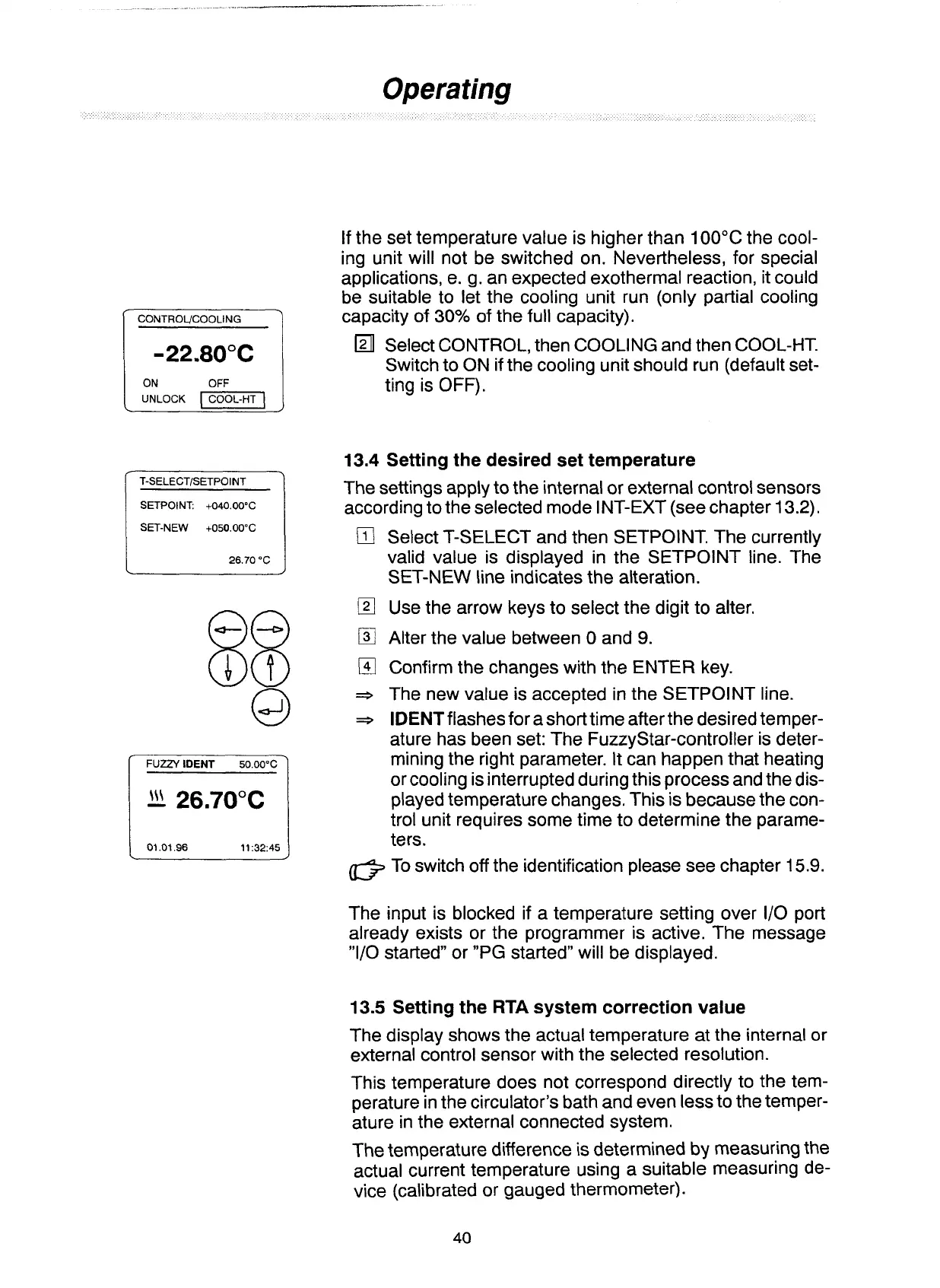

Select CONTROL, then COOLING and then COOL-HT.

Switch to ON if the cooling unit should run (default set-

ting is OFF).

13.4 Setting the desired set temperature

The settings apply to the internal or external control sensors

according to the selected mode INT-EXT (see chapter

13.2).

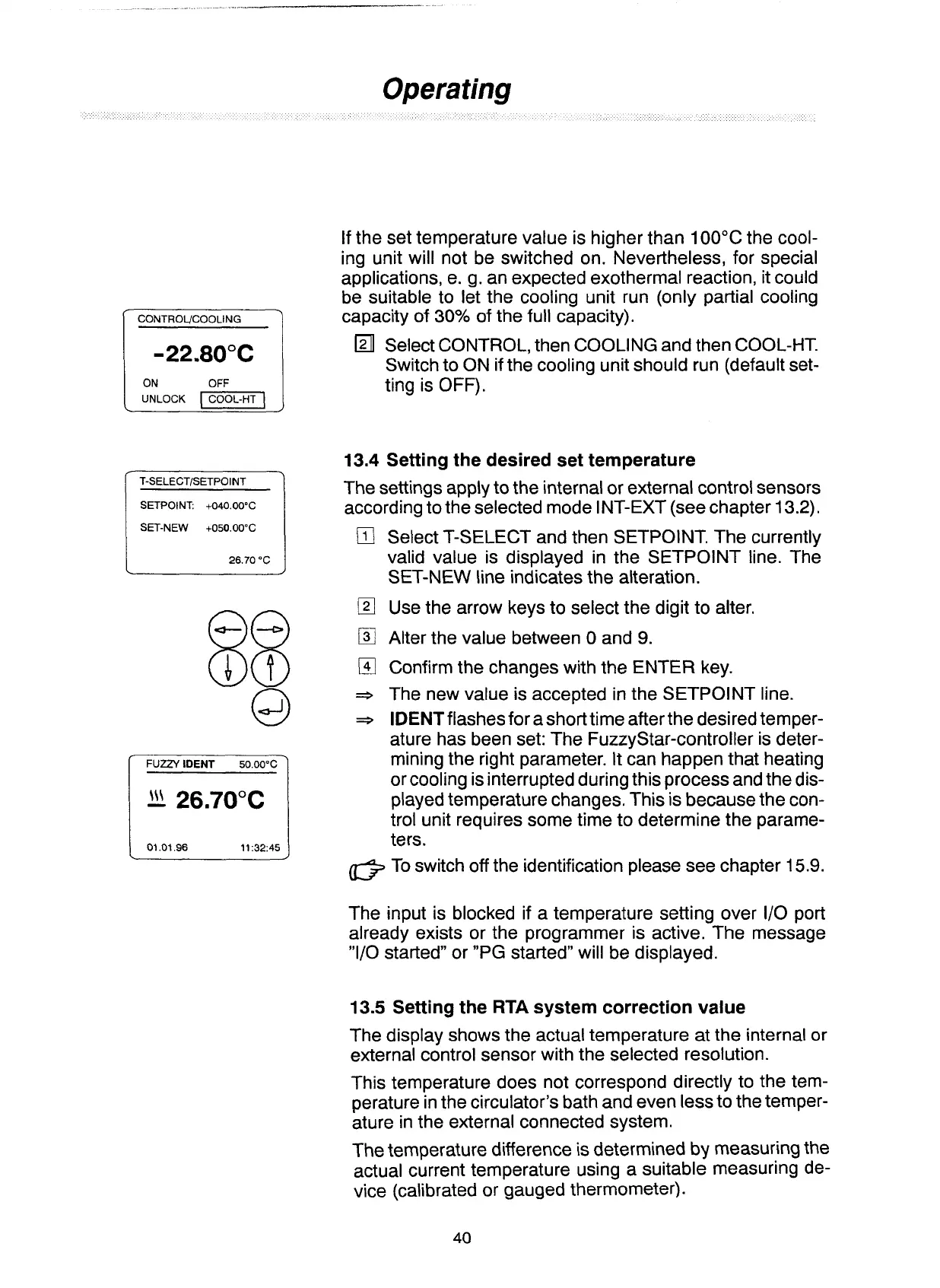

Select T-SELECT and then SETPOINT. The currently

valid value is displayed in the SETPOINT line. The

SET-NEW line indicates the alteration.

Use the arrow keys to select the digit to alter.

Alter the value between

0 and

9.

Confirm the changes with the ENTER key.

The new value is accepted in the SETPOINT line.

IDENTflashesfor ashort time after the desired temper-

ature has been set: The

FuzzyStar-controller is deter-

mining the right parameter. It can happen that heating

or cooling is interrupted during this process and the dis-

played temperature changes. This is because the con-

trol unit requires some time to determine the parame-

ters.

To switch off the identification please see chapter

15.9.

The input is blocked if a temperature setting over I10 port

already exists or the programmer is active. The message

"110

started" or

"PG

started" will be displayed.

13.5 Setting the

RTA

system correction value

The display shows the actual temperature at the internal

or

external control sensor with the selected resolution.

This temperature does not correspond directly to the tem-

perature in the circulator's bath and even less to the temper-

ature in the external connected system.

The temperature difference

is

determined by measuring the

actual current temperature using a suitable measuring de-

vice (calibrated or gauged thermometer).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...