• valves

• pipe bends

• the suction side of any pumps

• a CO

2

injection system or similar

Note: There may be situations where not all the above conditions can be met. If this is the case, or you have any

concerns, please consult your Hach representative to appraise the situation and define the best applicable solution.

5.2.2 Sensor insertion

Note: Check that the small O-ring at the bottom of the flow chamber is present during removal and installation of

the sensor, as it may stick to the sensor head and fall.

• Insert the sensor straight into the flow chamber or socket.

• Hand tighten the attaching collar.

• Connect the sensor cable.

• Check for leaks; replace O-rings if product leaks are visible.

Note: Do not twist the sensor when inserting it into a micro volume flow chamber. This rotation may twist the

membrane holding ring, thus changing the membrane position. This can modify the membrane measuring

conditions, and affect measurement precision.

5.2.3 Sensor removal

• Shut off the sample flow and drain the sampling circuit of liquid or gas.

• Remove the sensor cable connected at the sensor end.

• Hold the sensor body in one hand to avoid rotation and unscrew the collar with the other hand.

• Pull the sensor straight out of the socket or flow chamber.

• Check that both O-rings remain in place inside the flow chambers.

• Install the sensor storage cap and sensor base (to protect the connection).

Section 6 Maintenance

W A R N I N G

Multiple hazards. Only qualified personnel must conduct the tasks described in this section of the

document.

6.1 Maintenance schedule

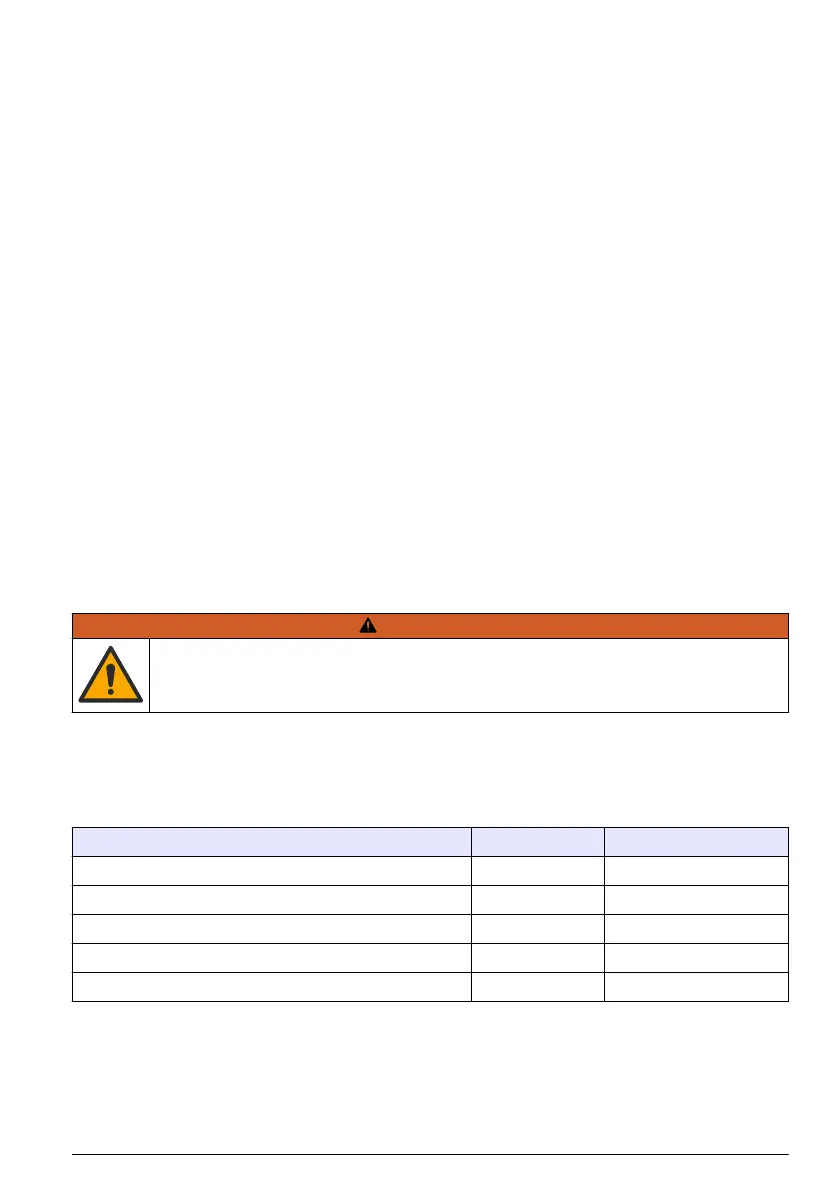

The following table shows the recommended schedule for membrane replacement. The table should

only be used as a guideline, as maintenance intervals will vary depending on a number of different

parameters (e.g. water chemistry, CIP frequency, oxygen levels, sample temperature, etc.).

Application Membrane type Membrane replacement

Water applications (> 10 ppb) 2956A Every 3 to 6 months

Pure water applications (power and electronics < 10 ppb) 2956A Every 3 to 6 months

Beer in-line 2952A Every 3 to 6 months

Portable or lab applications 2952A or 2958A Every 3 to 6 months

Wort in-line 29552A or 2995A Every 1 or 2 months

6.2 Prerequisites for sensor maintenance

The following table lists the prerequisites for a sensor maintenance:

English

13

Loading...

Loading...