20

Installation

3.3.5 Installing the 3-way ball valves

CAUTION

Installation should be performed by qualified technical

personnel to ensure adherence to all applicable electrical and

plumbing codes.

Refer to the Auto Flush Kit Instruction Sheet (Cat. No. 46692-88)

for complete installation instructions.

3.4 Installing a sample line

Sample lines should be a diameter that is appropriate for the

sample type. Choose a line size that minimizes lag time, but also

minimizes plugging with solids.

• Route the sample line as directly as possible.

• Using long or large diameter sample lines will result in a

significant lag time between actual process conditions and

instrument measurements.

• When larger diameter sample lines or long distances are

unavoidable, increase flow to the instrument and bypass

excess flow to the drain or back to process.

• Install sample line taps into larger process pipes to minimize

the chances of ingesting sediment from the pipe-line bottom or

air bubbles from the top. A tap projecting into the center of the

pipe is ideal. Figure 11 shows both good and poor methods of

installing a sample tap.

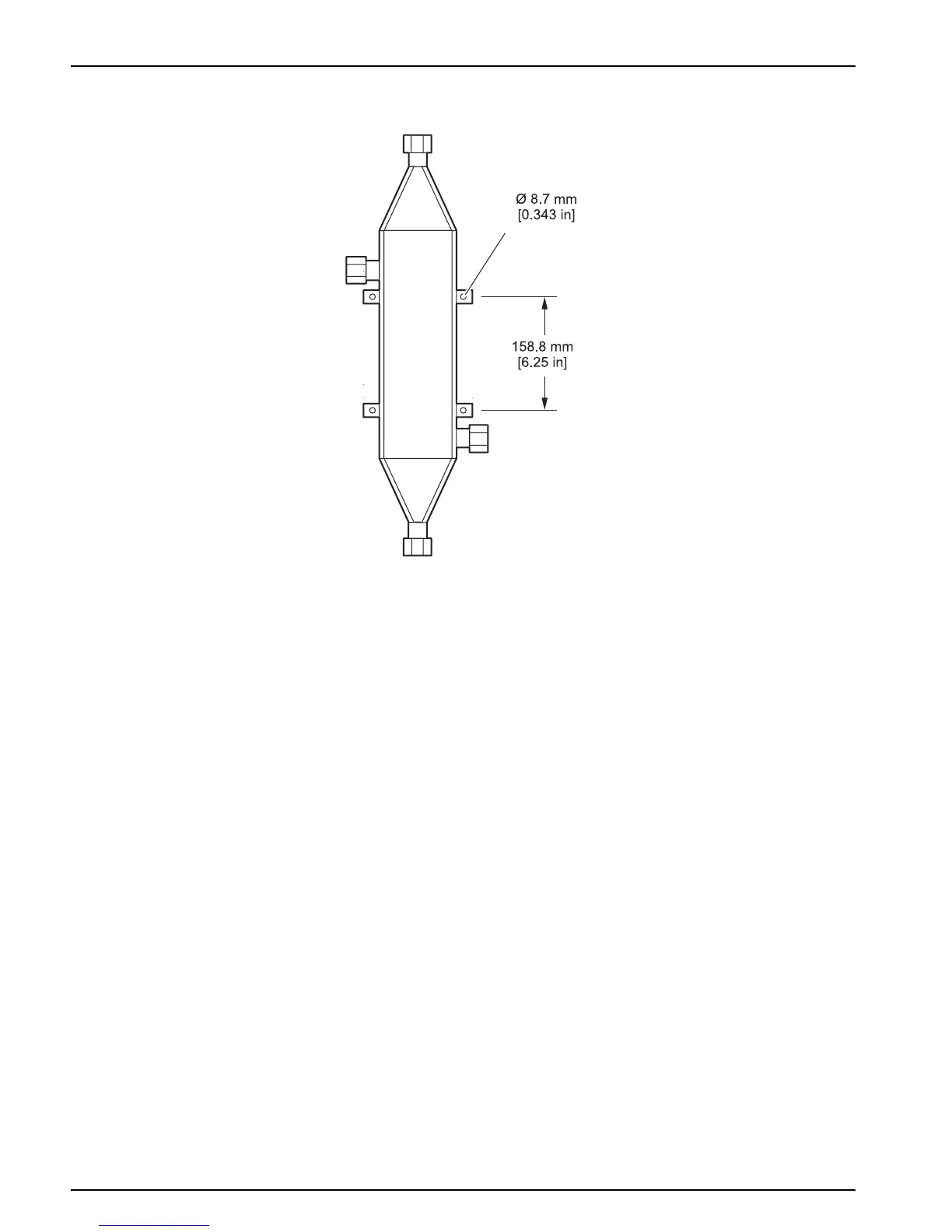

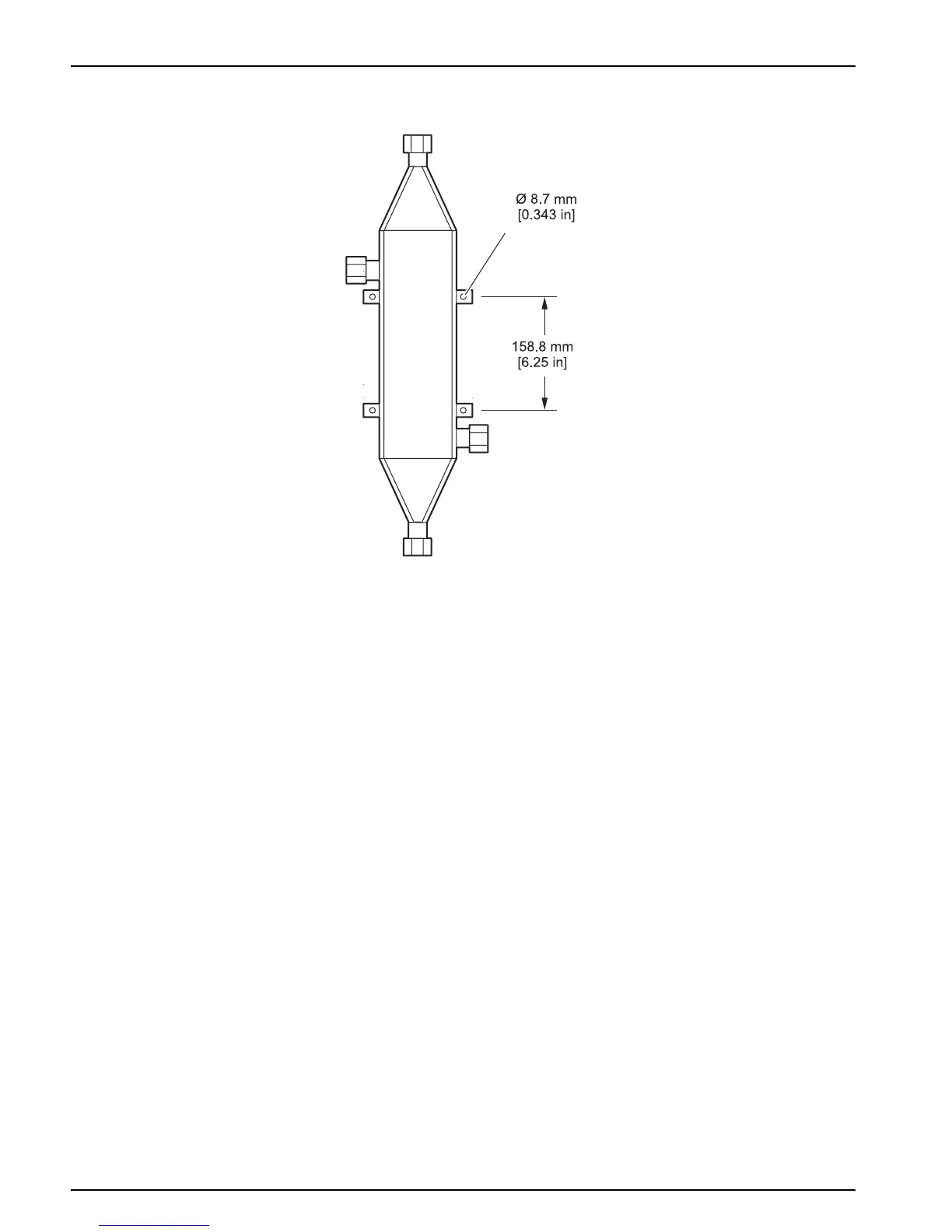

Figure 10 Heat exchanger dimensions

Loading...

Loading...