41

6.1.4 Power on

6.1.5 Search and Lock Outdoor \ Indoor Unit

6.1.6 Trial Operation and Parameters Record

1. For the protection of the compressor, It is required to preheat the compressor oil 6 hours before unit start up. Six

hours of preheating is the standard time for preheating. Commissioning technicians must wait for 6 hours until the

compressor oil reaches the required temp. The main PCB will show on the LED time counting down.

2. The outdoor and indoor units communication P, Q should be disconnected before turning on indoor units in case

of premature start up.

1. Search: Set BM1-1 at o to search outdoor unit, set BM1-2 at o to search indoor unit.

2. Lock: When ensuring that the displayed indoor units, valve boxes and outdoor units quantity is equal to that of

actually installed, the indoor, valve box and outdoor units quantity can be locked. The locking method is to set the

master module dip switch BM1-1 and BM1-2 from OFF to ON.

1. The oil temperature startup requirement is 60º Fahrenheit, high speed fan in cooling mode and 86º degree

Fahrenheit, high speed fan in heating mode. The following is the example when using wired controllers for temp.

display.

2. In cooling or in heating mode, let the outdoor and indoor units run for 1 hour;

3. Record for the rst time after the unit running for 1 hour, and then record every half an hour for 5 times.

4. Running Parameters Checking Standard.

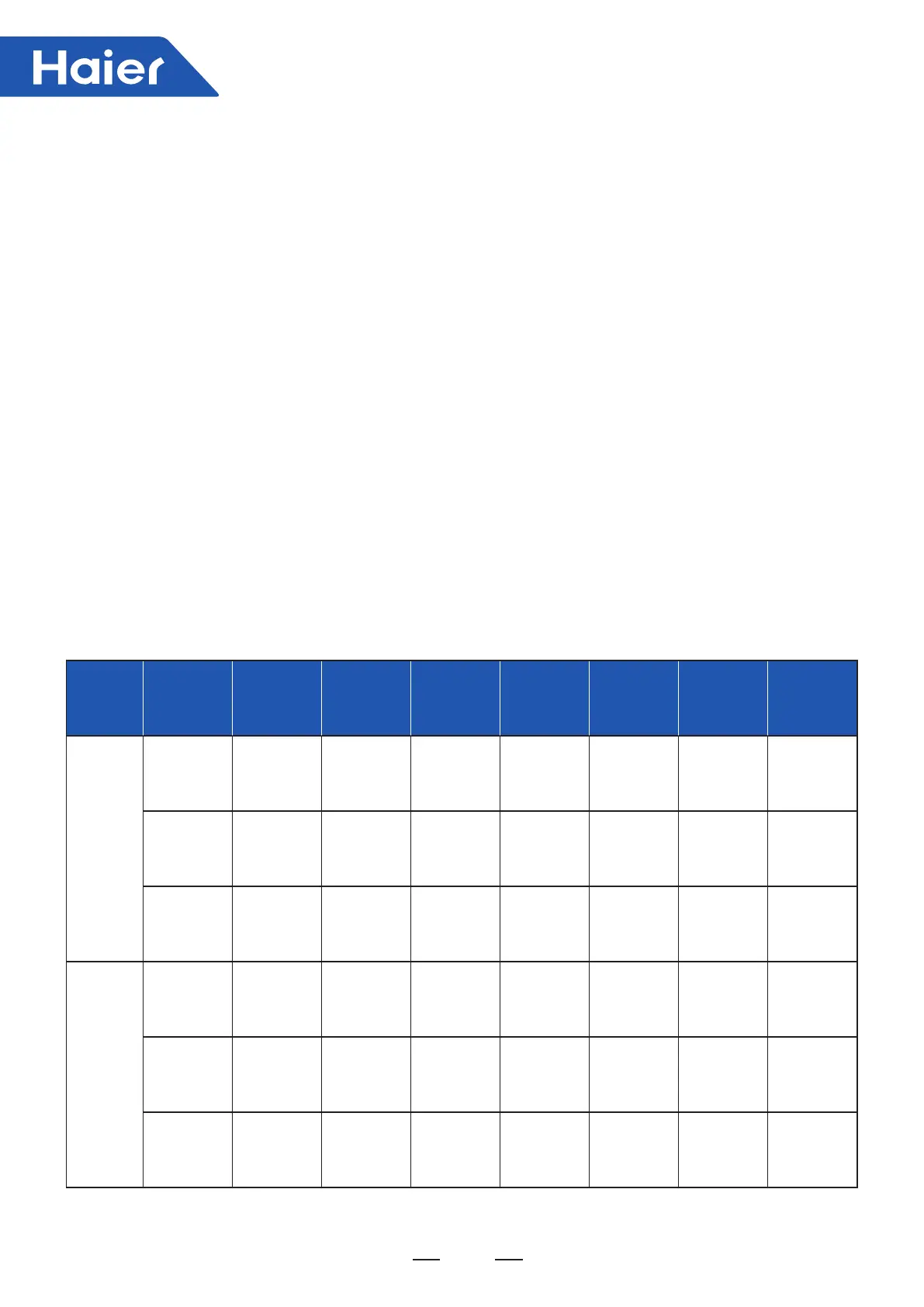

Mode TA Pd(psi) Ps(MPa) Toil Td(°F) Ts

Outdoor

EEV

Indoor EEV

Cooling

18~27 217~348 0.4~0.85 closed to Td 140~230 -68~86°F 250 60~480

28~35 246~464 0.5~0.9 closed to Td 140~230 -68~86°F 250 60~480

above 35 290~420 0.7~1.05 closed to Td 140~230 -68~86°F 250 60~480

Heating

below -5 232~406 0.1~0.4 closed to Td 140~230 -68~86°F 60-350 200~480

-5~7 275~406 0.3~0.8 closed to Td 140~230 -68~86°F 60-350 200~480

above 7 319~522 0.8~1.05 closed to Td 140~230 -68~86°F 60-350 200~480

Loading...

Loading...