4

1.2 Mounting

Mountthedryeronalevelsolidsurface.Holesareprovidedin

thedryerbasetopermanentlymountthedryertotheoor.

1.3 Piping Connections

A. AirInlet-Connectcompressedairlinefromairsource

toairinlet.(Referencemarkingsondryerorseecallout

drawingonpage13forairinlet/outletconnectionloca-

tions.)

NOTE: Customer piping needs to be properly supported.

Useback-upwrenchwhenmakingpipingconnections.

RefertoSerialNumberTagformaximum

workingpressure.Donotexceeddryer’sMaximumWorking

Pressure.

NOTE: Install dryer in air system at highest pressure possible

(e.g.beforepressurereducingvalves).

NOTE: Install dryer at coolest compressed air temperature

possible.Maximuminletcompressedairtemperature:120°F

(49°C).Ifinletairexceedsthistemperature,precooltheair

withanaftercooler.

B. AirOutlet–Connectairoutlettodownstreamairlines.

NOTE: Customer piping needs to be properly supported.

Useback-upwrenchwhenmakingpipingconnections.

C. Bypasspiping–Ifservicingthedryerwithoutinterrupting

the air supply is desired, piping should include inlet and

outlet valves and an air bypass valve.

D. Watercooledmodels–coolingwaterinletandoutlet

1. Connect cooling water supply to cooling water inlet.

2. Connect cooling water return line to cooling water

outlet connection.

NOTE: Strainer and water regulating valve are supplied on

water cooled models.

1.4 Electrical Connections

IMPORTANT: Use copper supply wires only.

A. Dryer is designed to operate on the volt-

age,phase,andfrequencylistedonthe

serial number tag.

B. Electrical entry on larger dryers is through

a hole in the cabinet. It is located on the right side panel

whenfacingthefrontoftheunit.Connectpowersource

to terminal strip in electrical enclosure as shown on the

wiring diagram included with the dryer.

NOTE:Refrigerationcondensingunitisdesignedtoruncon-

tinuously and should NOTbewiredtocycleon/offwiththeair

compressor.

1.5 Moisture Separator

A. Separatorhasanexternaldrainwhichauto-

matically discharges collected condensate.

NOTE: It may be desirable to pipe the con-

densatefromtheAutomaticDrainoutlettoa

suitable drain.

B. Formanualdraining,convenientdryerdepressurization,

and drain valve maintenance, a three-way valve assembly

is installed between the drain port on the moisture separa-

tor and the drain valve. On all models, the three-way

valveismountedtothebasepan.Reviewthefollowing

forproperdrainfunction:

• AutomaticDraining-Valvehandleshouldbepositioned

paralleltothevalvebody(asshown),withthearrow

on the handle pointing toward the drain valve. In this

position,condensatewillowfromthebowltothedrain

valve.

• DrainIsolation(Shutdown)-Valvehandleshallbe

turnedperpendiculartothevalvebody(rotate90°).In

thisposition,condensateowisshutoff.

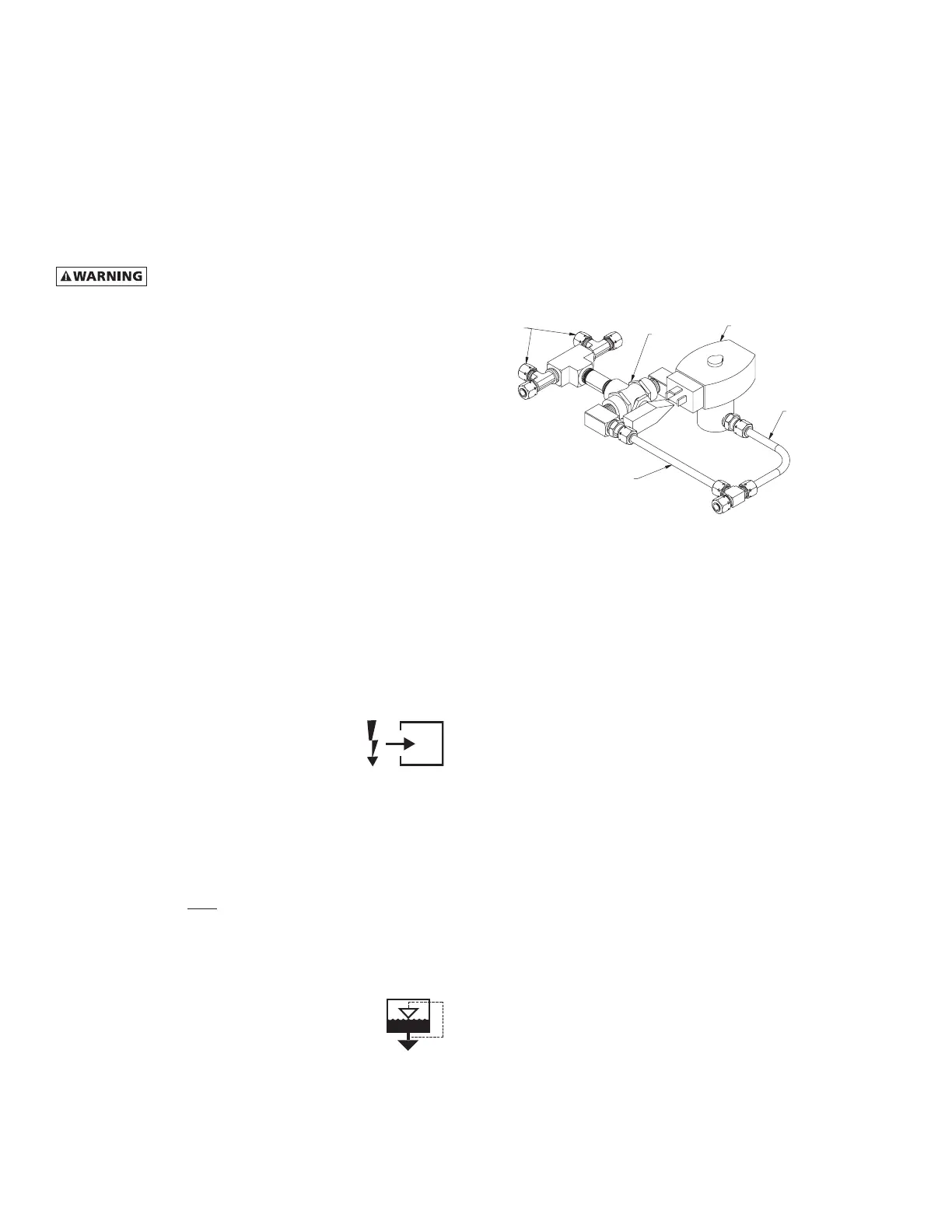

Solenoid Valve

Automatic Discharge

Line

Manual Discharge Line

3-Way Valve

Drain Inlets

• ManualDraining-Drainvalvehandleshallberotated

slightly past the drain isolation position to allow

throttlingthroughthevalveformanualdischargeand

depressurization.

NOTE: Discharge is at system pressure. Drain line should be

anchored.

NOTE: Condensate may contain oil. Comply with applicable

laws concerning proper disposal.

Loading...

Loading...