7

Procedure for Separator / Filter Element Replacement

THIS FILTER IS A PRESSURE CONTAINING

DEVICE. DEPRESSURIZE BEFORE SERVICING.

1. Isolatedryer(closeinletandoutletvalvesifinstalled)or

shutoffairsupply.

2. Removefrontpanelanddepressurizelterbyslowlyopen-

ing manual drain by-pass valve.

3. Disconnectdrainlinefrombottomofseparator.

4. Disassemblelterhousing.

a. Forallmodels-removethelterbowl,unscrewingit

fromthelterheadbyhandorstrapwrench.

5. Cleanlterbowl.

6. Remove and replace complete element.

a. Unscrewtheoldlterelementanddiscard.Also,

discardthesmallO-ringthatsealstheltertothelter

assembly head.

7. InstallnewlterelementandbowlwithnewO-ringsprop-

erlyseatedtoheadorbowl(dependentupondryersize).

8. Connect drain line and replace panel.

9. Repressurizedryerandresumeoperation.

3.3 Check separator daily to be sure automatic drain is

discharging.

3.4 Blow down separator weekly by pushing test button

on control panel.

3.5 Rebuild drain mechanism annually.

Tofacilitateservice,maintenancekitsareavailable.

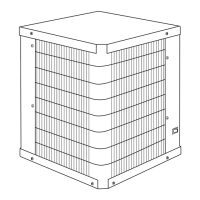

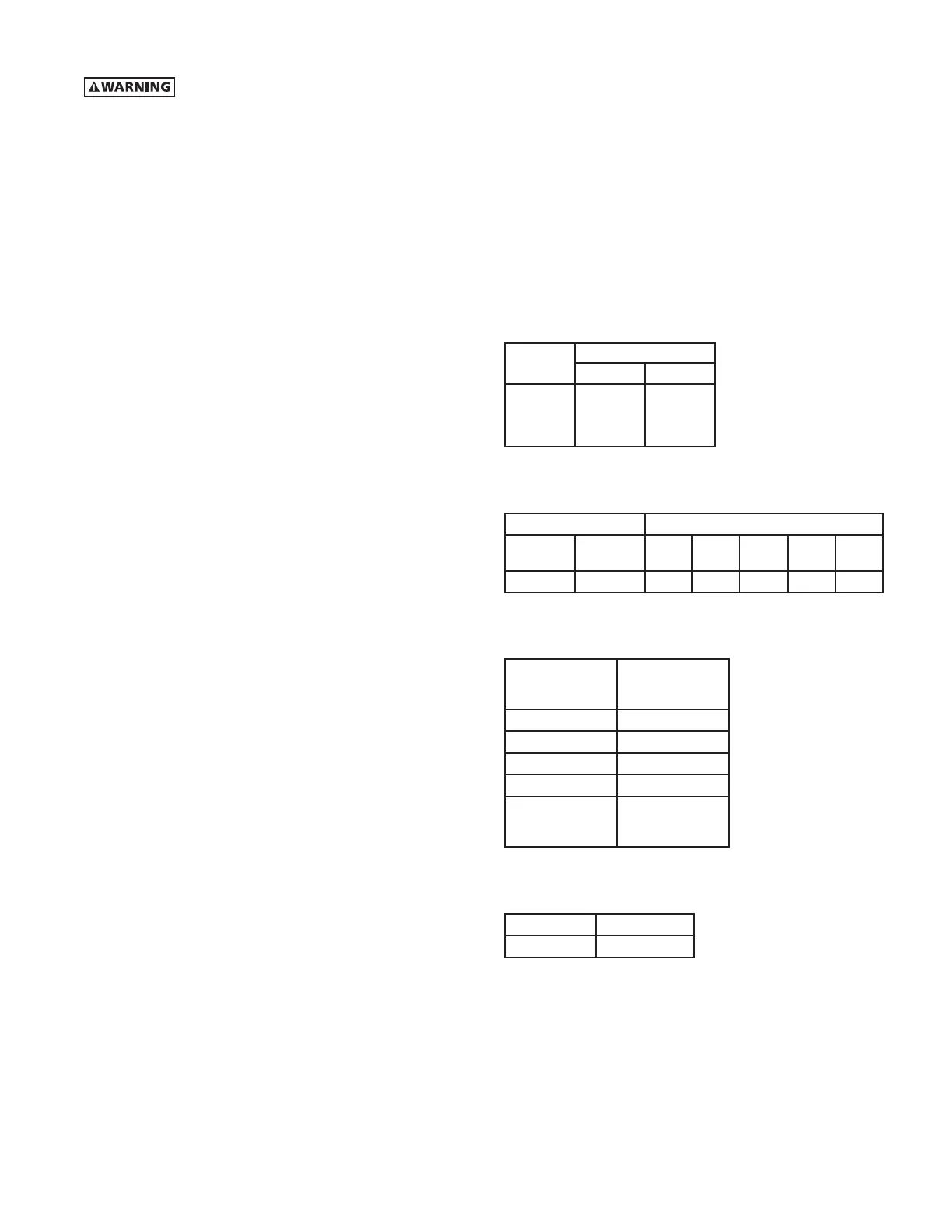

SIZING

Determining dryer capacity at actual operating conditions

Todeterminethemaximuminletowcapacityofadryeratvari-

ousoperatingconditions,multiplytheratedcapacityfromTable

1 by the multipliers shown in Table 2.

Example:Howmanyscfmcananair-cooledmodel4handle

when compressed air to be dried is at 350 psig and 90°F; am-

bient air temperature is 80°F?

Answer:1250x1.19x1.12=1666scfm.

Table 1. Rated Capacity

Ratedcapacity(scfm)@725psiginletpressure,100°Finlet

temperature,and100°Fambienttemperatureand60Hertz

operation.

MODEL

RATED FLOW

(scfm) m

3

/hr

4

6

7.5

10

1250

1750

2000

3000

2125

2975

3400

5100

Table 2. Capacity Adjustment Factors for Air Inlet

Temperature and Pressure

INLET PRESSURES INLET TEMPERATURES

(psig) (barg)

80°F

27°C

90°F

32°C

100°F

38°C

110°F

32°C

120°F

49°C

300 to 725 21 to 50 1.49 1.19 1.00 0.83 0.72

Table 3. Capacity Adjustment Factors for Ambient Air

Temperature

AMBIENT

TEMPERATURE

°F (°C)

CAPACITY

ADJUSTMENT

FACTOR

80°F(27°C) 1.12

90°F(32°C) 1.06

100°F(38°C) 1.00

110°F(32°C) 0.94

Water-cooled

(85°F, 29.4°C

coolingwater)

1.15

Table 4. Capacity Adjustment Factors for Electrical

Frequency

50 Hertz 60 Hertz

0.83 1.00

Loading...

Loading...