6

2.4 Timer Drain Programming Mode

1. Pressthe“DrainIntervalProgram”button.The“Conden-

sateDraining”LEDwillstarttoash,andtheilluminated

LEDonthe“DewPointTemperatureIndicator”willidentify

thefactorysettingfor“MinutesBetweenDrainCycles.”

(SeeTable1)

2. Pressandreleasethe“DrainIntervalSelector”buttonto

sequencethe“MinutesBetweenDrainCycleLED’s”from

lefttorightuntilreachingyourselection.The“Red”LEDis

notused(ReferenceTable2for“DrainCycleIntervals”)

3. Toinitiatethenewsetting,pressthe“DrainIntervalPro-

gram”button(thiswillstorethenewsettingandexitthe

program).

4. ExitingtheProgramwillcausetheTimerDraintodis-

charge and begin a new cycle.

NOTE:Failuretoperformstep3within25secondsofcom-

pletingstep2willcausetheunittorevertbacktotheprevious

setting.

NOTE:Intheeventofabrieforextendedperiodofpower

loss,theunitwillretaintheexistingprogramsettingandwill

begin a new cycle once power is reapplied. Had drain been

readytodrainbeforethelossofpower,thedrainbowl’scapac-

itywouldpreventdownstreamooding.Condensatewilldrain

completelywithinacoupleofcycles.(Manuallypressingthe

“Push-to-Test”buttonwoulddrainbowlimmediately)

2.5 Operating Check Points

Checkthefollowingonaperiodicbasis:

A. Green power on light is illuminated.

B. Dew point indicator is in green area.

C. Condensateisdischargingfromdrain.

Condensate Draining

(Flashes in

programmingmode)

Drain Interval

Program

Dew Point

Temperature

Indicator

Drain Interval

Selector

(LED illuminated

indicates drain

cyclesetting)

3.0 MAINTENANCE

3.1 Condenser Coil

A. Air-cooled-cleanoffaccumulateddustanddirtmonthlyor

as necessary in dirty environments.

B. Water-cooled-cleanstrainermonthly,moreoftenif

required.Shutoffwater,removesmallplugtorelievepres-

sure, then remove large plug to remove strainer. Clean

strainer and replace.

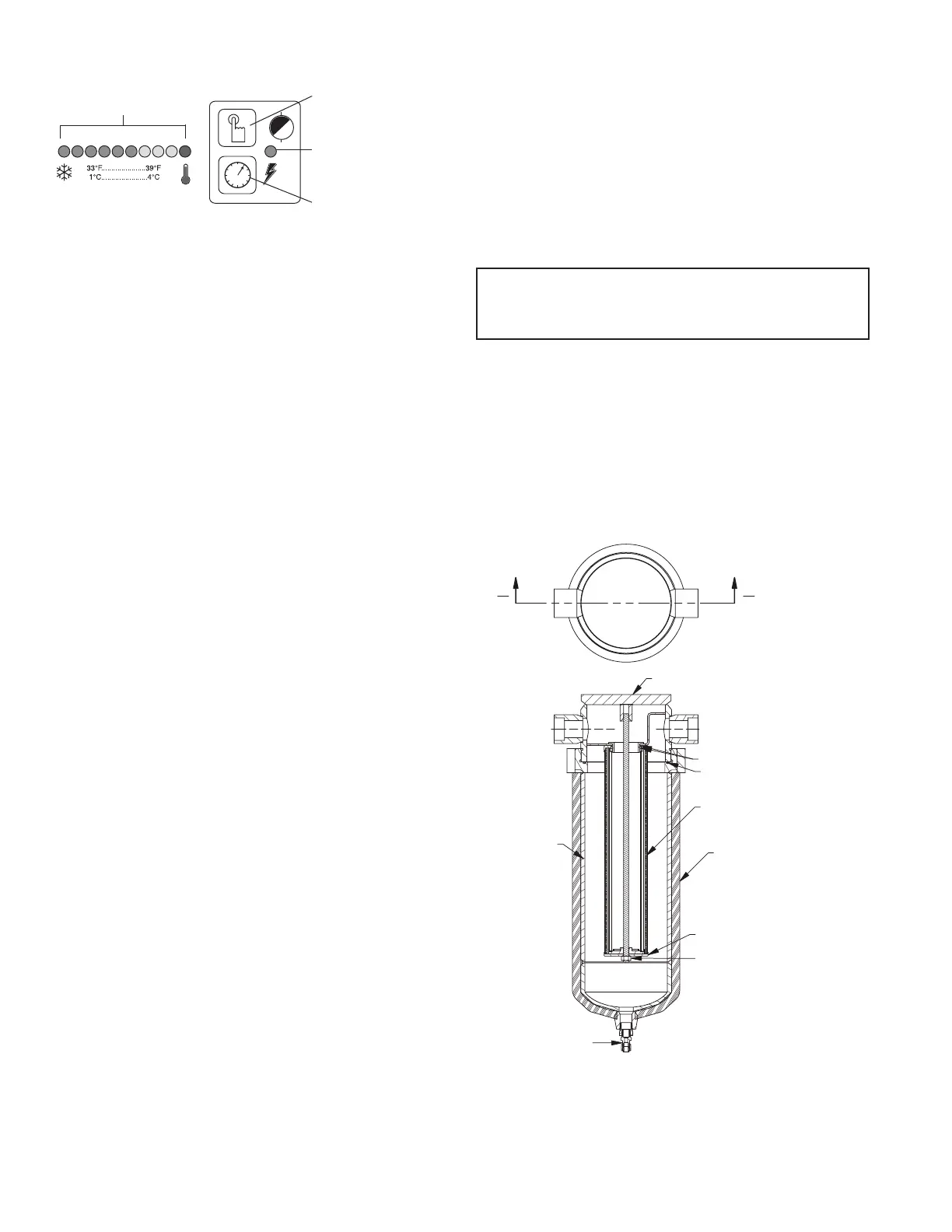

3.2 Moisture Separator/Oil Removal Filter

NOTE: Prepackagedmaintenancekitsareavailablethat

includeallnecessarylterandtimeddrainvalvecomponents.

MaintainmaximumperformanceandefciencywithGenuine

Parts.Seepage15fororderinginformation.

When to replace the Separator/Filters

Replacelterelementannually,orwhenpressuredrop

acrossdryerisexcessive.

Whenremovingliquidsatratedowconditions,anin-

creaseinpressuredropwilloccurastheseparator/lter

elements become loaded with solid particles.

A A

Separator Head

Separator Element O-Rings

Separator Bowl O-Ring

Separator Element Replacement Sleeve

Separator Bowl Insulation

Separator Element Bottom Cap

Separator Element Nut

Drain Compression Fitting

Separator Bowl

Air Inlet

Air Outlet

Loading...

Loading...