18

GB 05 06 03 04

Sprayer setup

HyHy

HyHy

Hy

drdr

drdr

dr

aulics - joaulics - jo

aulics - joaulics - jo

aulics - jo

yy

yy

y

sticstic

sticstic

stic

k handle (type Z only)k handle (type Z only)

k handle (type Z only)k handle (type Z only)

k handle (type Z only)

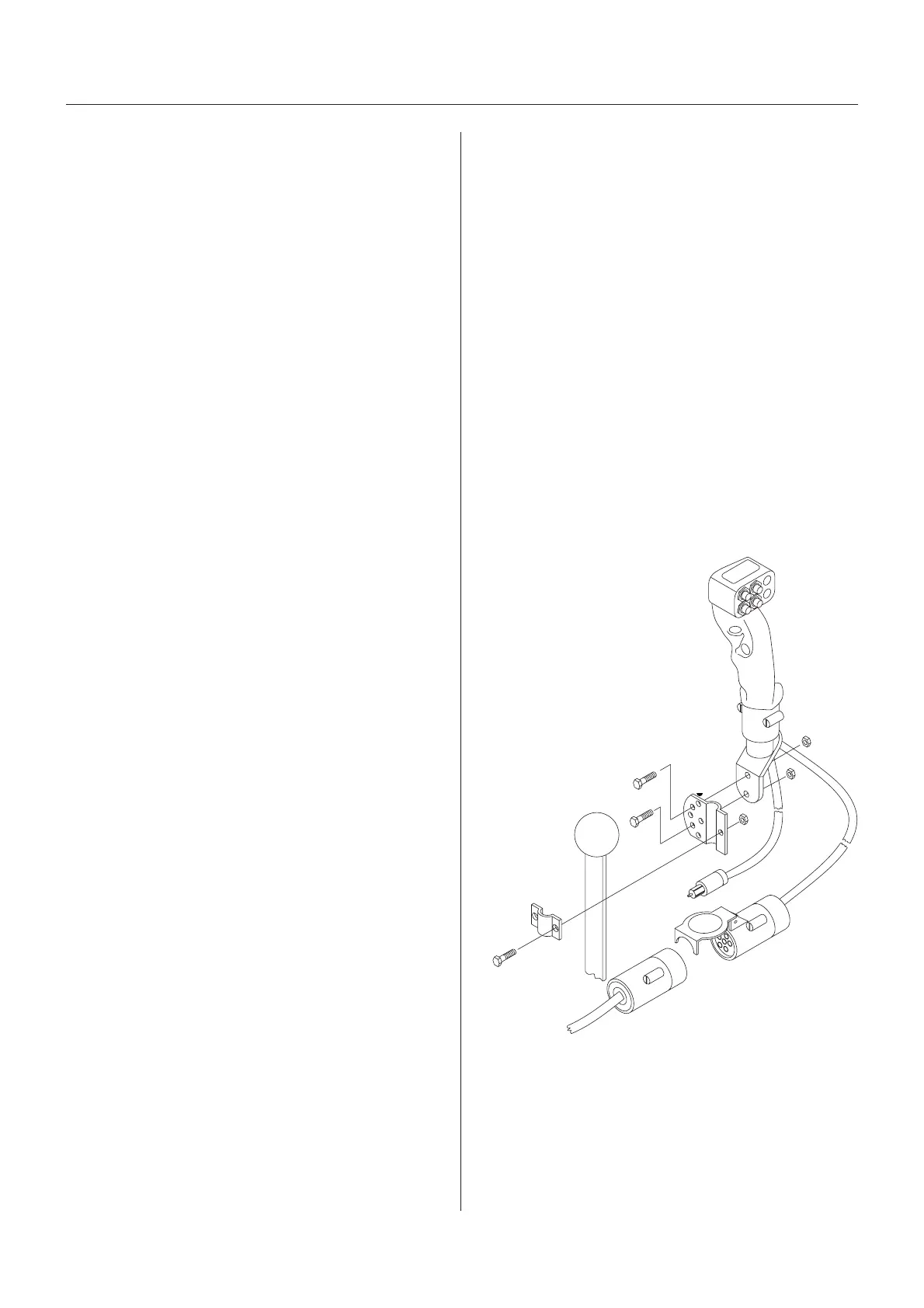

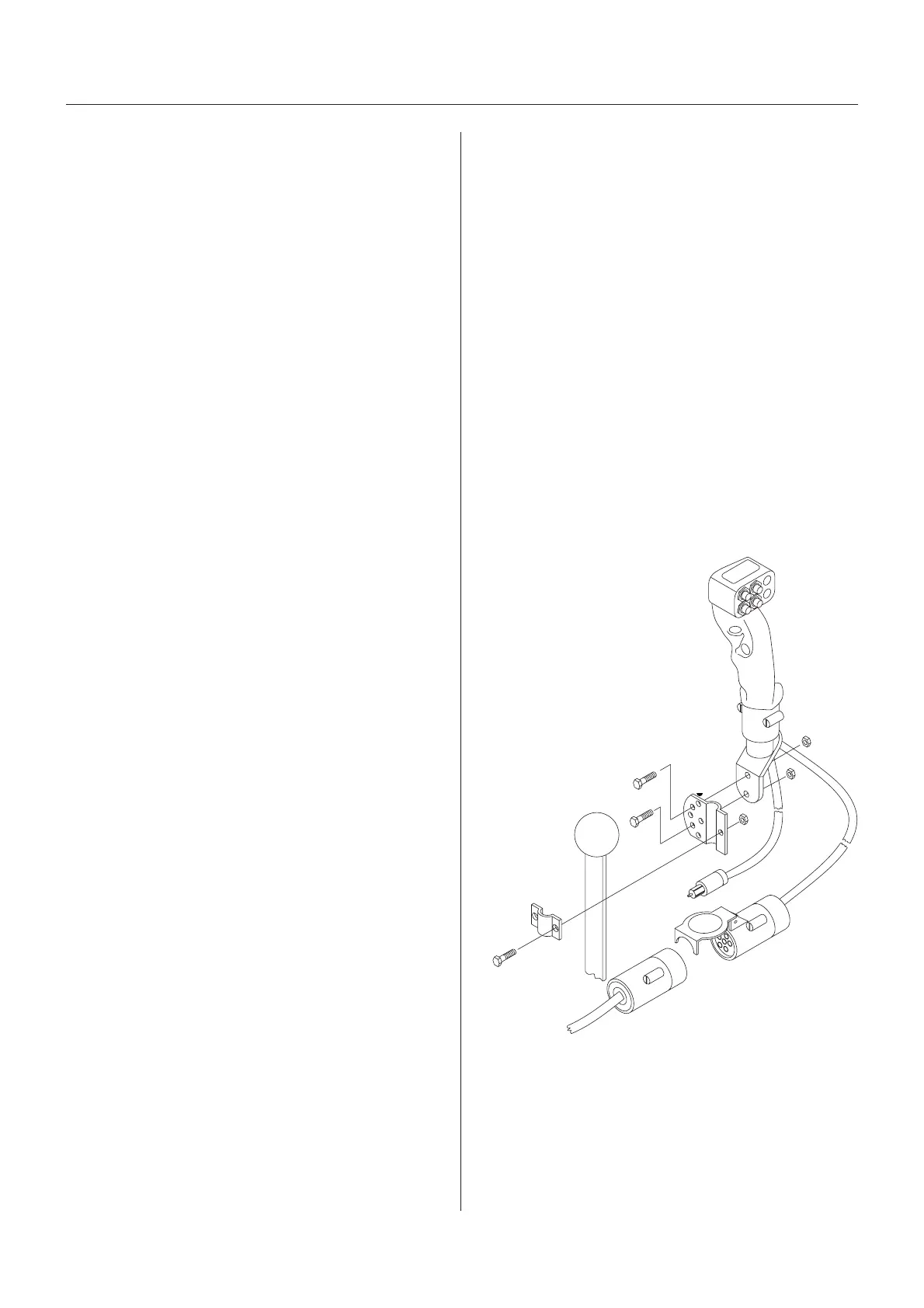

Installation of handle

1. Attach the control handle/joystick A to the hydraulic

lever that operates the double acting outlet to be

used. The universal mounting bracket B is very

flexible and a number of different mounting positions

can be used.

2. Connect the plug C to the tractors 12V power system.

Try to hook-up the handle as close as possible to the

battery power supply. HARDI recommends using an

electric distribution box (ref. no. 817925) to ensure a

good power supply to various 12V attachments.

Note! Check with your dealer or tractor operators

manual for the best location to hook up the 12V system.

Note polarity: BROWN wire = Positive (+)

BLUE wire = Negative (-)

3. Connect electric plug D from sprayers hydraulics to

plug E on handle.

HyHy

HyHy

Hy

drdr

drdr

dr

aulic syaulic sy

aulic syaulic sy

aulic sy

stemsstems

stemsstems

stems

Indirect Acting Hydraulic system (I.A.H.)

Connection requirements for SPB-Y and SPB-Z are:

One single acting outlet for the lift function of the

spray boom

One double acting outlet for the folding function

Ensure that snap couplers are clean before connection!

NOTE! The hydraulic system requires a minimum oil

pressure of 130 bar, max. oil pressure of 210 bar and an

oil capacity of approx. 5 litres. After having operated the

boom and the system has been filled with oil, check

tractors hydraulic oil level and top up if necessary.

IMPORTANT! Due to the variation in tractor hydraulic

systems and capacities, care should be exercised when

initially operating the sprayer hydraulic cylinders. It is

advisable to adjust the hydraulic flow control down to the

minimum rate before operating the system. Adjust/

increase the flow control after the system is bled of any

air, if necessary.

Hydraulic lever

A

B

C

D

E

T045-0011

Loading...

Loading...