39

GB 08 04

Operation

FF

FF

F

ilterilter

ilterilter

ilter

ss

ss

s

All filters should always be used, and their function

checked regularly. The mesh size of the filter in use

should always be smaller than the flow average of the

nozzles used. Therefore, pay attention to the correct

combination of filters, mesh size.

Self-cSelf-c

Self-cSelf-c

Self-c

leaning fleaning f

leaning fleaning f

leaning f

ilterilter

ilterilter

ilter

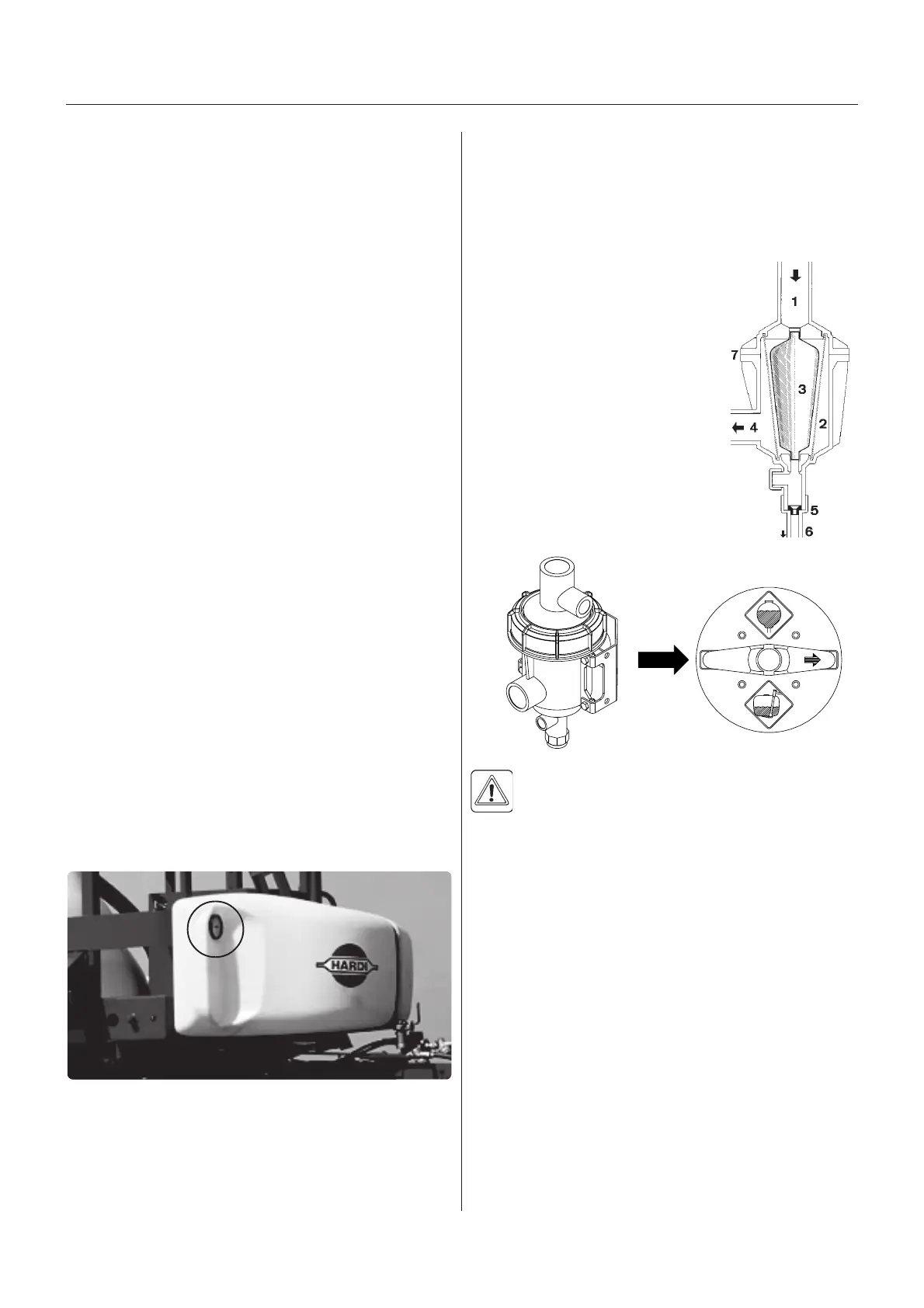

Operating diagram

1. From pump

2. Double filter screen

3. Guide cone

4. To operating unit

5. Replaceable restrictor

6. Return to tank

7. Screw-joint

The self-cleaning filter is operated

via the yellow MANIFOLD valve.

IMPORTANT! The yellow MANIFOLD valve

should normally be open, but must be closed in

the following cases:

1. If rinsing with water from the rinsing tank and a

quantity of spray liquid still remains in the main tank

(otherwise the spray liquid will be diluted).

2. If opening the self-cleaning filter and a quantity of

spray liquid still remains in the main tank (otherwise

there is a risk that spray liquid will flow out).

Choice of correct restrictor

It is important to have a large flow through the filter. This

is achieved by choosing the restrictor size in relation to

the liquid consumption of the spray boom.

4 restrictors are supplied. Use the green one (largest

orifice) first.

NOTE! HEREAFTER ADJUSTMENT OF PRESSURE

EQUALISATION WILL ONLY BE NEEDED WHEN:

1. YOU CHANGE TO NOZZLES WITH OTHER CA-

PACITIES

2. THE NOZZLE OUTPUT INCREASES AS THE NOZ-

ZLES WEAR

OperOper

OperOper

Oper

aa

aa

a

ting the contrting the contr

ting the contrting the contr

ting the contr

ol unit while sprol unit while spr

ol unit while sprol unit while spr

ol unit while spr

aa

aa

a

yingying

yingying

ying

In order to close the entire boom, switch ON/OFF A to

off position. This returns the pump output to the tank

through the return system.

The diaphragm Non-drip valves ensure instantaneous

closing of all nozzles.

In order to close one or more sections of the boom,

switch the relevant distribution valve V to off position.

The pressure equalisation ensures that the pressure

does not rise in the sections which are to remain open.

When the sprayer is put aside, the control box and the

multi plug must be protected against moisture and dirt.

A plastic bag may be used to protect the multi plug.

RR

RR

R

emote premote pr

emote premote pr

emote pr

essuressur

essuressur

essur

e ge g

e ge g

e g

augaug

augaug

aug

e (ife (if

e (ife (if

e (if

f f

f f

f

itted)itted)

itted)itted)

itted)

The remote pressure gauge is integrated in the front

locker. This gauge measures the working pressure in the

boom tubes as close to the nozzles as possible. This

pressure reading will always be slightly lower than the

reading at the operating unit pressure gauge.

The outputs stated in the nozzle charts are always based

on the pressure measured at the nozzle.

Always adjust pressure when calibrating and spraying

according to readings at the Remote pressure gauge.

(If no front locker is fitted to the trailer the pressure

gauge is situated at the platform instead).

T059-0001

T060-0118

T026-0096

Loading...

Loading...