70

GB 14 08 04

Maintenance

Occasional maintenance Occasional maintenance

Occasional maintenance Occasional maintenance

Occasional maintenance

The maintenance and renewal intervals for the following

will depend very much on the conditions under which the

sprayer will be operated and are therefore impossible to

specify.

Pump vPump v

Pump vPump v

Pump v

alvalv

alvalv

alv

es and diaes and dia

es and diaes and dia

es and dia

phrphr

phrphr

phr

aa

aa

a

gms rgms r

gms rgms r

gms r

eneene

eneene

ene

ww

ww

w

alal

alal

al

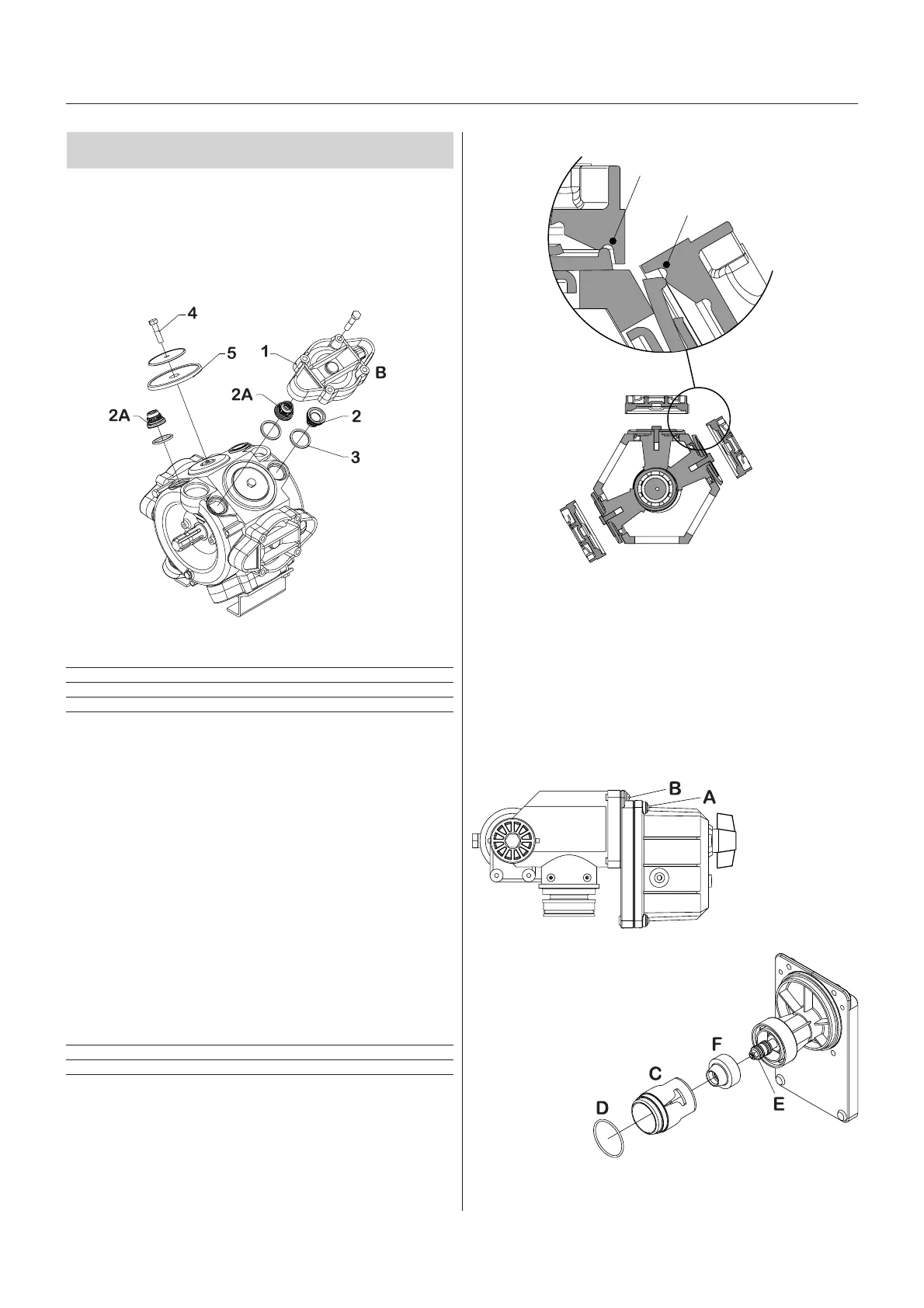

Diaphragm pump overhaul kit (valves, seals, diaphragms etc.)

Pump model HARDI part No.

363 750342

463 750343

Valves

Remove valve cover 1 before changing the valves 2 -

note their orientation so they are replaced correctly!

NOTE! A special valve with white flap 2A is used at the

two upperside inlets. It has to be placed in the valve

openings as shown. All others are the type with black flap.

It is recommended to use new gaskets 3 when changing

or checking the valves.

Diaphragms

Remove the diaphragm cover 4. The diaphragm 5 may

then be changed. If fluids have reached the crankcase,

re-grease the pump thoroughly. Also check that the drain

hole at the bottom of the pump is not blocked. Reas-

semble with the following torque setting.

Pump model Diaphragm cover Nm Diaphragm bolt Nm

463 90 90

463 90 90

1 Nm = 0.74 lbft

IMPORTANT! Before tightening the 4 bolts for the

diaphragm cover B the diaphragm must be positioned

between centre and top to ensure correct sealing be-

tween diaphragm pumphousing and diaphragm cover.

Turn crank shaft if necessary.

Cone cCone c

Cone cCone c

Cone c

hechec

hechec

hec

k/rk/r

k/rk/r

k/r

eneene

eneene

ene

ww

ww

w

al EVal EV

al EVal EV

al EV

C operC oper

C operC oper

C oper

aa

aa

a

ting unitting unit

ting unitting unit

ting unit

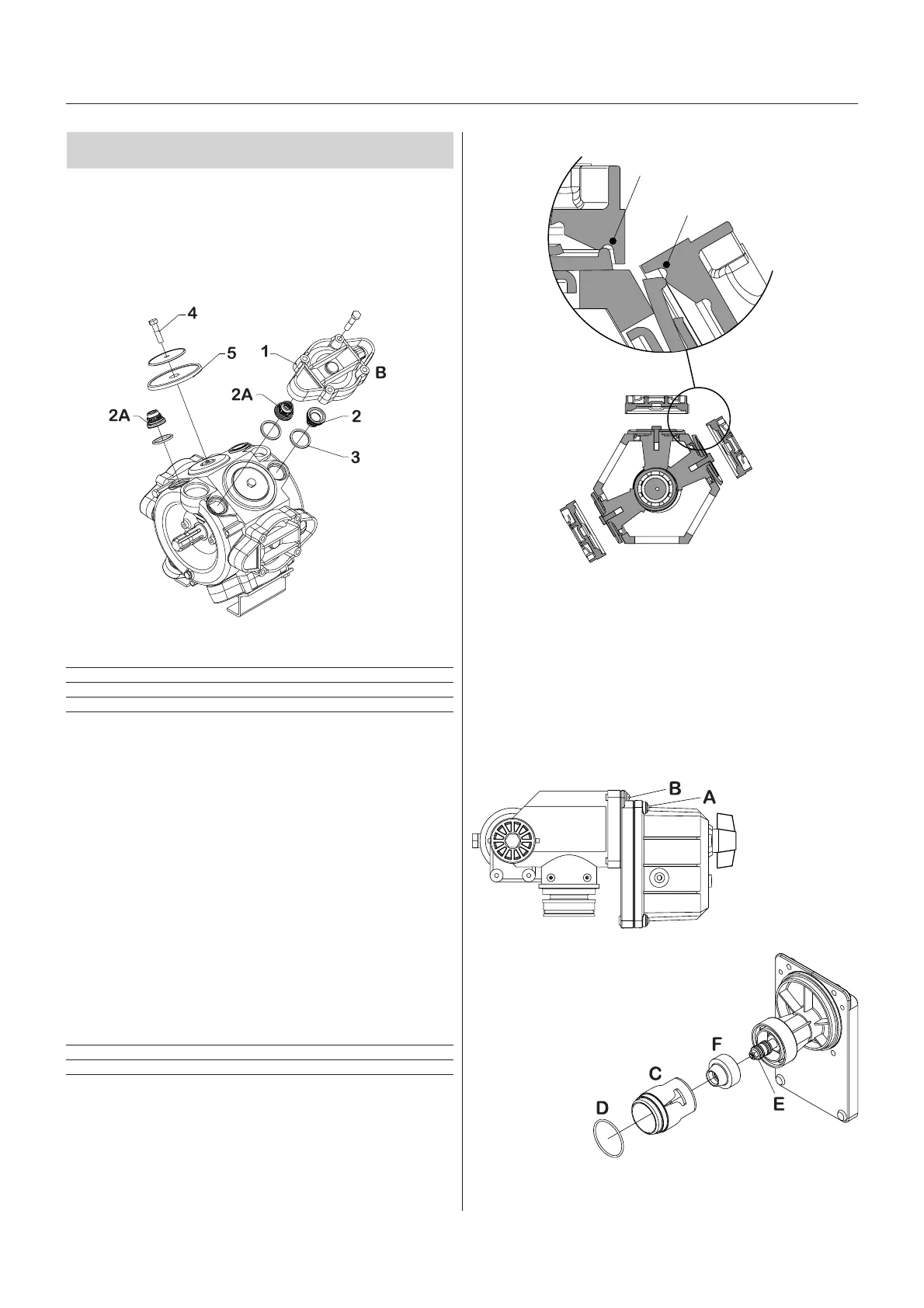

If it becomes difficult to build up sufficient pressure or if

pressure fluctuations occur, it may be necessary to

renew cone and cylinder. A HARDI kit is available for this

purpose. Ref. no. 741293.

1. Remove 4 x screws A and remove the housing.

2. Remove 4 x screws B.

3. Replace cylinder C and O-ring D.

4. Loosen the nut E, remove and replace

the cone F.

5. Reassemble in reverse

order.

T192-0005

correct

wrong

T192-0039

T261-0001

T192-0040

Loading...

Loading...