GB 08 00 MA

Operation - liquid system

FF

FF

F

illing ofilling of

illing ofilling of

illing of

c c

c c

c

hemicalshemicals

hemicalshemicals

hemicals

Chemicals can be filled in the tank in two ways:

1. Through tank lid.

2. HARDI FILLER chemical filling device.

WARNING! Always wear correct protective

clothing before handling chemicals!

1. F1. F

1. F1. F

1. F

illing thrilling thr

illing thrilling thr

illing thr

ough tank lidough tank lid

ough tank lidough tank lid

ough tank lid

The chemicals are filled through the tank lid - Note

instructions on the chemical container!

WARNING! Be careful not to slip or splash

chemicals when carrying chemicals up to the

tank lid!

1. Make sure the EVC is switched off.

2. Set the MANIFOLD valves to correct position. Black

valve “Suction from main tank”, green valve towards

“Agitation”

3. Engage the pump and set P.T.O. revolutions to 540

r/min.

4. Add the chemicals through the main tank hole.

5. When the spray liquid is well mixed, turn handle on

the Pressure Manifold towards “Spraying” position.

Keep P.T.O. engaged so the spray liquid is continu-

ously agitated until it has been sprayed on the crop.

2. HARDI FILLER c2. HARDI FILLER c

2. HARDI FILLER c2. HARDI FILLER c

2. HARDI FILLER c

hemical inductorhemical inductor

hemical inductorhemical inductor

hemical inductor

(optional equipment)(optional equipment)

(optional equipment)(optional equipment)

(optional equipment)

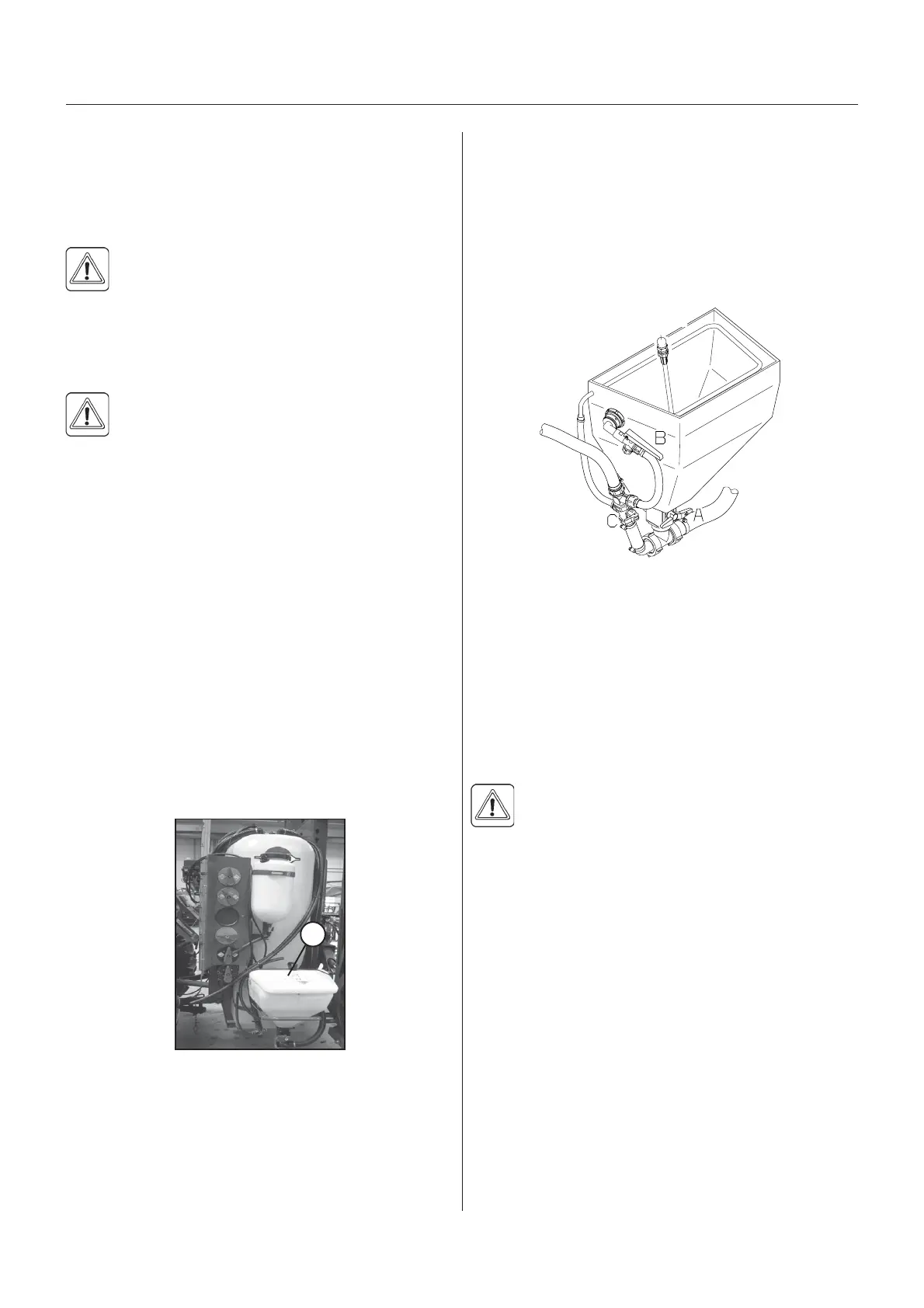

HARDI FILLER (G)

Filling of Liquid chemicals

1. Fill the main tank at least

1

/

3

with water (unless

something else is stated on the chemical container

label). See section “Filling of water”.

2. Turn the handle at the Suction Manifold towards

“Main tank”. Turn blue valve towards “Agitation and

NOTE! The scale in the hopper can only be used if the

sprayer is parked at level ground! It is recommended to

use a measuring jug for best accuracy.

7. Open the bottom valve A and the chemical is trans-

ferred to the main tank.

8. If the chemical container is empty it can be rinsed by

the container rinsing device (if fitted). Place the

container over the multi-hole nozzle and press the

lever B.

WARNING! Do not press lever B unless the

multi-hole nozzle is covered by a container to

avoid spray liquid hitting the operator.

IMPORTANT! Rinsing device uses spray liquid to rinse

containers for concentrated chemicals. Always rinse the

chemical containers with clean water several times until

they are clean before disposal.

9. Engage the hopper rinsing device by opening valve C.

10. Close valve C again when the hopper is rinsed.

IMPORTANT! The hopper rinsing device is using spray

liquid for rinsing the hopper for concentrated chemical!

The FILLER must always be cleaned together with the

rest of the sprayer when the spray job is done.

11. Close valve A and the FILLER lid again.

12. When the spray liquid is well mixed, turn handle on

the Pressure Manifold towards “Spraying” position.

Keep P.T.O. engaged so the spray liquid is continu-

ously agitated until it has been sprayed on the crop.

T102-0016

G

green valve towards “HARDI FILLER”. Close remain-

ing valves.

3. Check that bottom valve A at the FILLER is closed.

4. Engage the pump and set P.T.O. speed at 540 r/min.

5. Open FILLER lid.

6. Measure the correct quantity of chemical and fill it into

the hopper.

Loading...

Loading...