32 / 46

CHAIN SHARPENING

The chain is dampened by both use and improper handling (for example, unintentional

grounding, rocking, etc.).

A correctly sharp chain will make your work easier and safer. You will know the chain needs to

be sharpened by the size of sawdust and the fact that the cutting is slower, the chainsaw ‘cuts

under’ (the cutting line is not even), or the there is a visible damage to the cutting edges.

The chain can be sharpened in two ways. Using a file or a grinder. In general, we always sharpen

using a grinder after any contact with material other than wood and in case of noticeable

blunting. Use a file to for sharpening as needed and especially during breaks while working.

The chain is better to grind more often by a file and keep it sharp as you go along than having

it grinded once in a while. (Frequent sharpening by a file will not remove as much of the cutting

tooth and the chain will last longer.) File sharpening should be done with one to three strokes

each time the fuel tank is used up. It is necessary to understand how and what it cuts and to

know at least two sharpening angles for the correct sharpening of the saw chain. A common

mistake when sharpening the chain is that it is "sharpened" outside the cutting part in the tooth

gum. See the detail of the cutting tooth to understand.

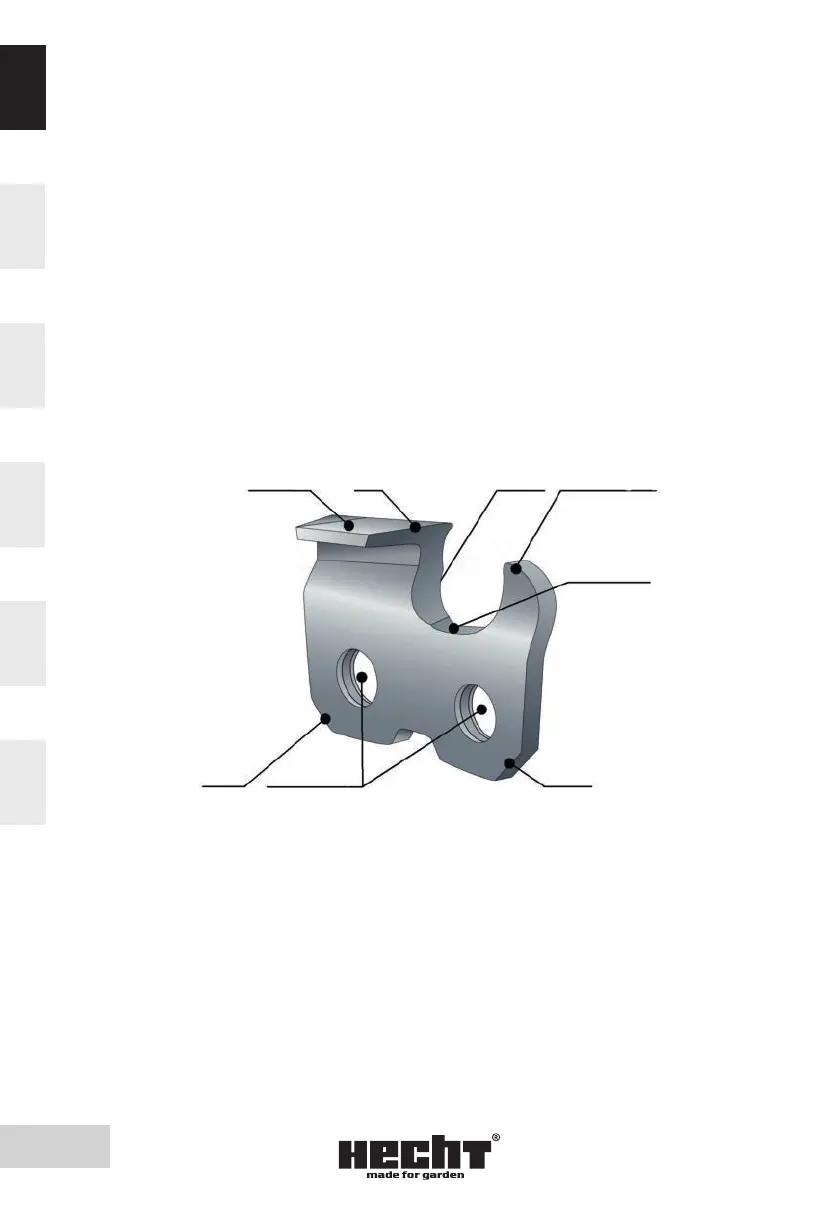

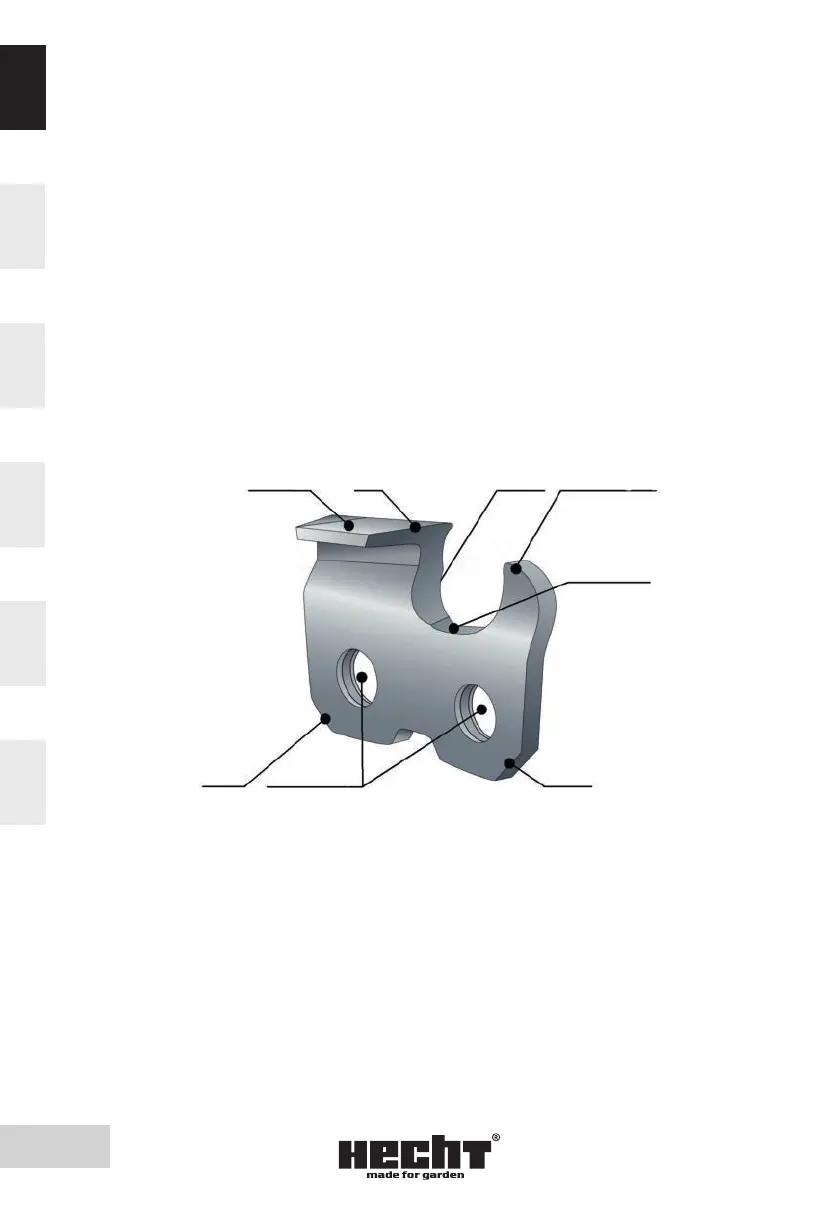

Top plate Cutting corner

Side plates

Depth gauge

Gullet

Heet

Rivet hole

Toe

As can be seen from the drawing, the edge is the highest point on a tooth and so it is necessary

to sharpen it in particular and not just the side of a tooth.

The sharpening is done with a round file of a diameter indicated by the chain producer. In

addition to the file diameter, the angle of sharpening and the horizontal angle must be known

for proper chain sharpening. The angle of the edge is given by the file diameter.

HECHT_925_R_MANUAL_2022_EN.indd 32HECHT_925_R_MANUAL_2022_EN.indd 32 28.03.2023 11:58:0328.03.2023 11:58:03

Loading...

Loading...