8 Programming: Cycles

162

ú

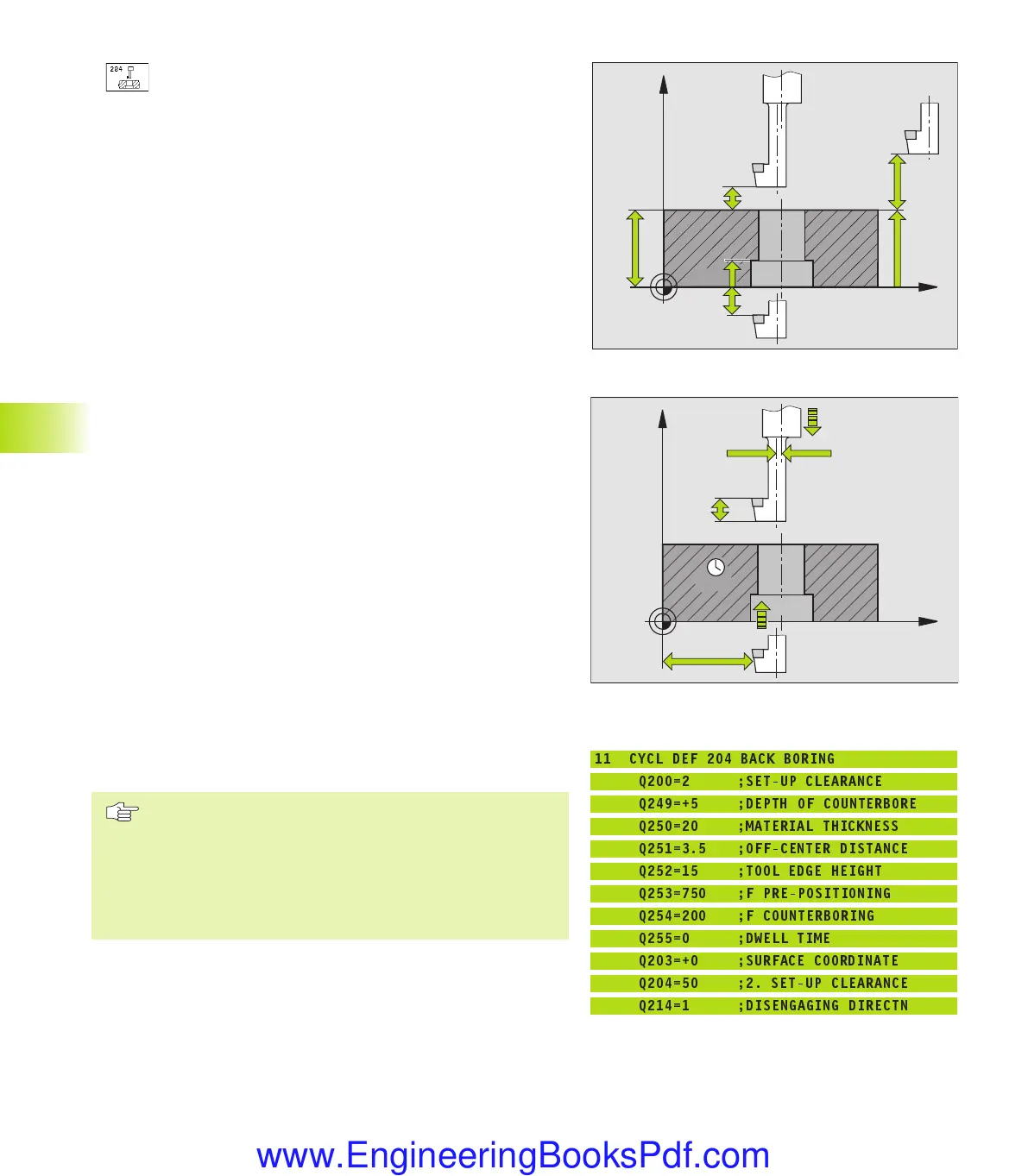

Set-up clearance Q200 (incremental value): Distance

between tool tip and workpiece surface.

ú

Depth of counterbore Q249 (incremental value):

Distance between underside of workpiece and the

top of the hole. A positive sign means the hole will be

bored in the positive spindle axis direction.

ú

Material thickness Q250 (incremental value): Thickness

of the workpiece

ú

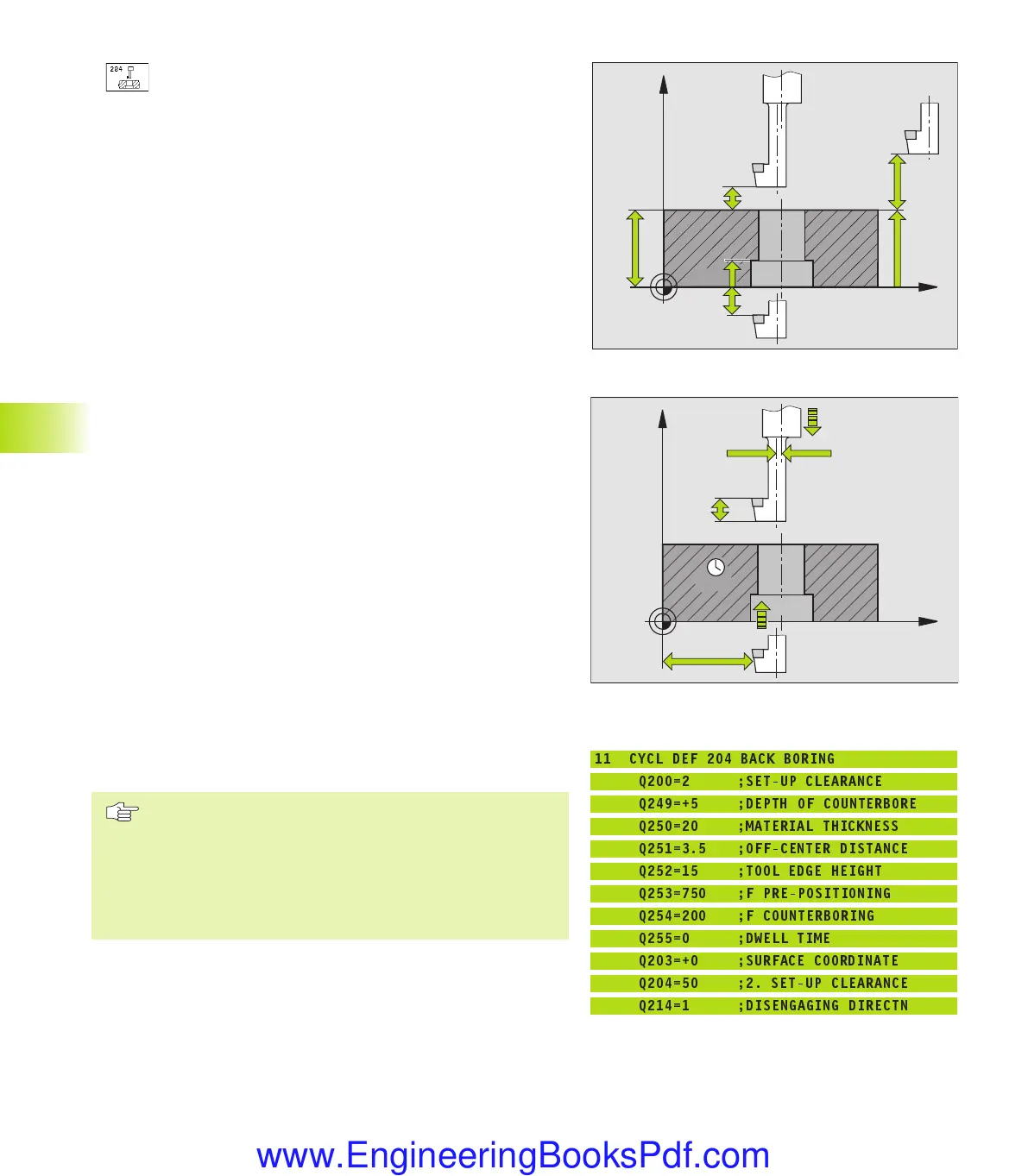

Off-center distance Q251 (incremental value): Off-

center distance for the boring bar; value from tool data

sheet

ú

Tool edge height Q252 (incremental value): Distance

between the underside of the boring bar and the main

cutting tooth; value from tool data sheet

ú

Feed rate for pre-positioning Q253: Traversing speed

of the tool when moving in and out of the workpiece,

in mm/min

ú

Feed rate for counterboring Q254: Traversing speed of

the tool during counterboring in mm/min

ú

Dwell time Q255: Dwell time in seconds at the top of

the bore hole

ú

Workpiece surface coordinate Q203 (absolute value):

Coordinate of the workpiece surface

ú

2nd set-up clearance Q204 (incremental value):

Coordinate in the tool axis at which no collision

between tool and workpiece (clamping devices) can

occur.

ú

Disengaging direction (0/1/2/3/4) Q214: Determine the

direction in which the TNC displaces the tool by the

off-center distance (after spindle orientation).

1: Displace tool in the negative main axis direction

2: Displace tool in the negative secondary axis direction

3: Displace tool in the positive main axis direction

4: Displace tool in the positive secondary axis direction

Danger of collision!

Check the position of the tool tip when you program a

spindle orientation to 0° (for example, in the Positioning

with Manual Data Input mode of operation). Align the

tool tip so that it is parallel to a coordinate axis. Select a

disengaging direction in which the tool can plunge into

the hole without danger of collision.

8.2 Drilling Cycles

X

Z

Q250

Q203

Q204

Q249

Q200

Q200

X

Z

Q255

Q254

Q214

Q252

Q253

Q251

Example NC blocks:

11 CYCL DEF 204 BACK BORING

Q200=2 ;SET-UP CLEARANCE

Q249=+5 ;DEPTH OF COUNTERBORE

Q250=20 ;MATERIAL THICKNESS

Q251=3.5 ;OFF-CENTER DISTANCE

Q252=15 ;TOOL EDGE HEIGHT

Q253=750 ;F PRE-POSITIONING

Q254=200 ;F COUNTERBORING

Q255=0 ;DWELL TIME

Q203=+0 ;SURFACE COORDINATE

Q204=50 ;2. SET-UP CLEARANCE

Q214=1 ;DISENGAGING DIRECTN

kkap8.pm6 30.06.2006, 07:03162

www.EngineeringBooksPdf.com

Loading...

Loading...