10 Programming: Q Parameters

252

10.1 Principle and Overview

10.1 Principle and Overview

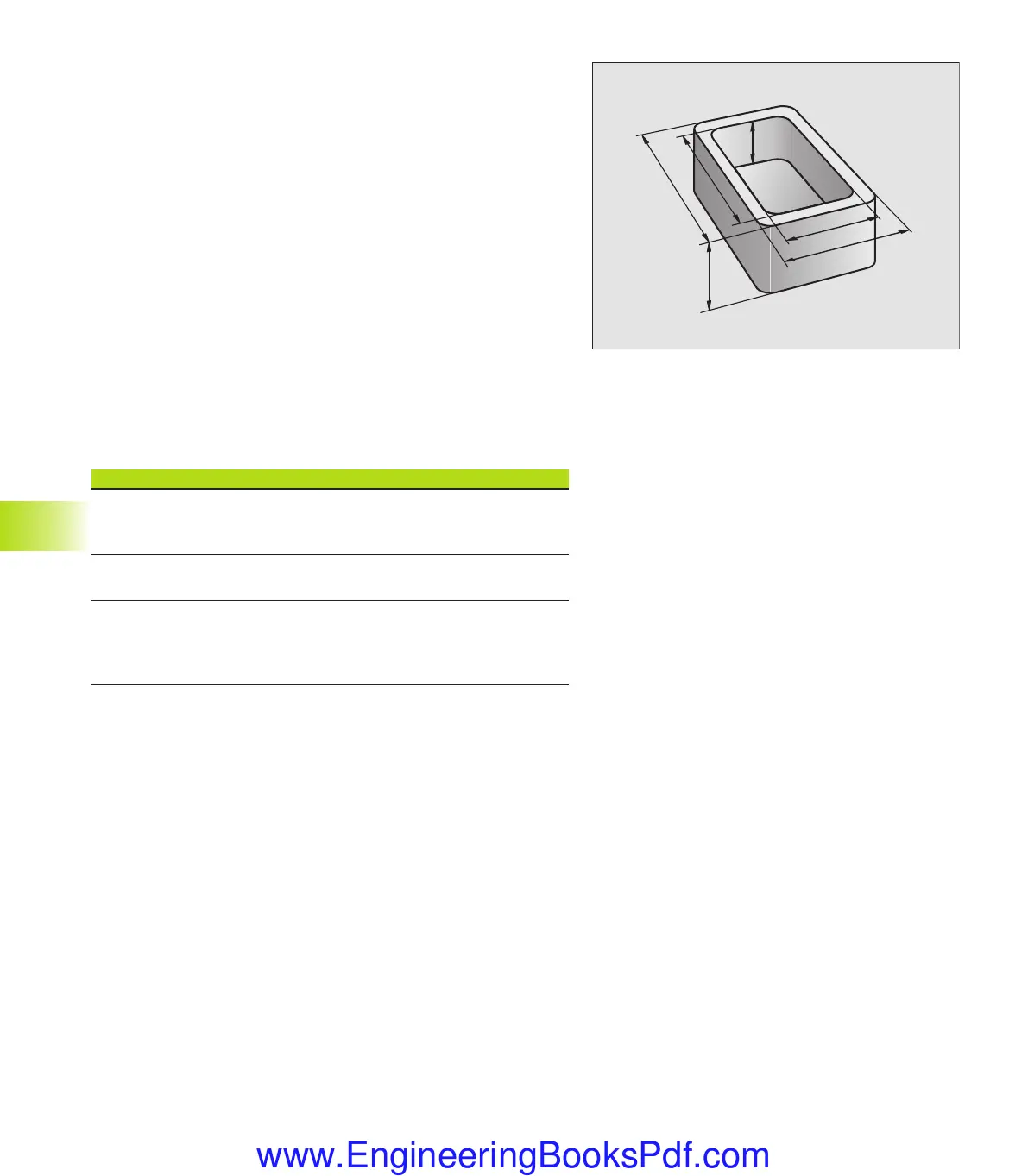

You can program an entire family of parts in a single part program.

You do this by entering variables called

Q parameters

instead of

fixed numerical values.

Q parameters can represent information such as:

■ Coordinate values

■

Feed rates

■

RPM

■

Cycle data

Q parameters also enable you to program contours that are defined

through mathematical functions. You can also use Q parameters to

make the execution of machining steps depend on logical

conditions. In conjunction with FK programming you can also

combine contours that do not have NC-compatible dimensions with

Q parameters.

Q parameters are designated by the letter Q and a number between

0 and 299. They are grouped according to three ranges:

Meaning Range

Freely applicable parameters, global Q0 to Q99

for all programs in the TNC memory.

Parameters for special TNC functions Q100 to Q199

Parameters that are primarily used for cycles, Q200 to Q399

globally effective for all

programs that are stored in the TNC memory

Programming notes

You can mix Q parameters and fixed numerical values within a

program.

Q parameters can be assigned numerical values between

–99 999.9999 and +99 999.9999. Internally, the TNC can calculate

up to a width of 57 bits before and 7 bits after the decimal point

(32-bit data width corresponds to a decimal value of 4 294 967 296).

Q4

Q2

Q3

Q1

Q5

Q6

MKAP10.PM6 30.06.2006, 07:04252

www.EngineeringBooksPdf.com

Loading...

Loading...