217HEIDENHAIN TNC 426 B, TNC 430

Before programming, note the following:

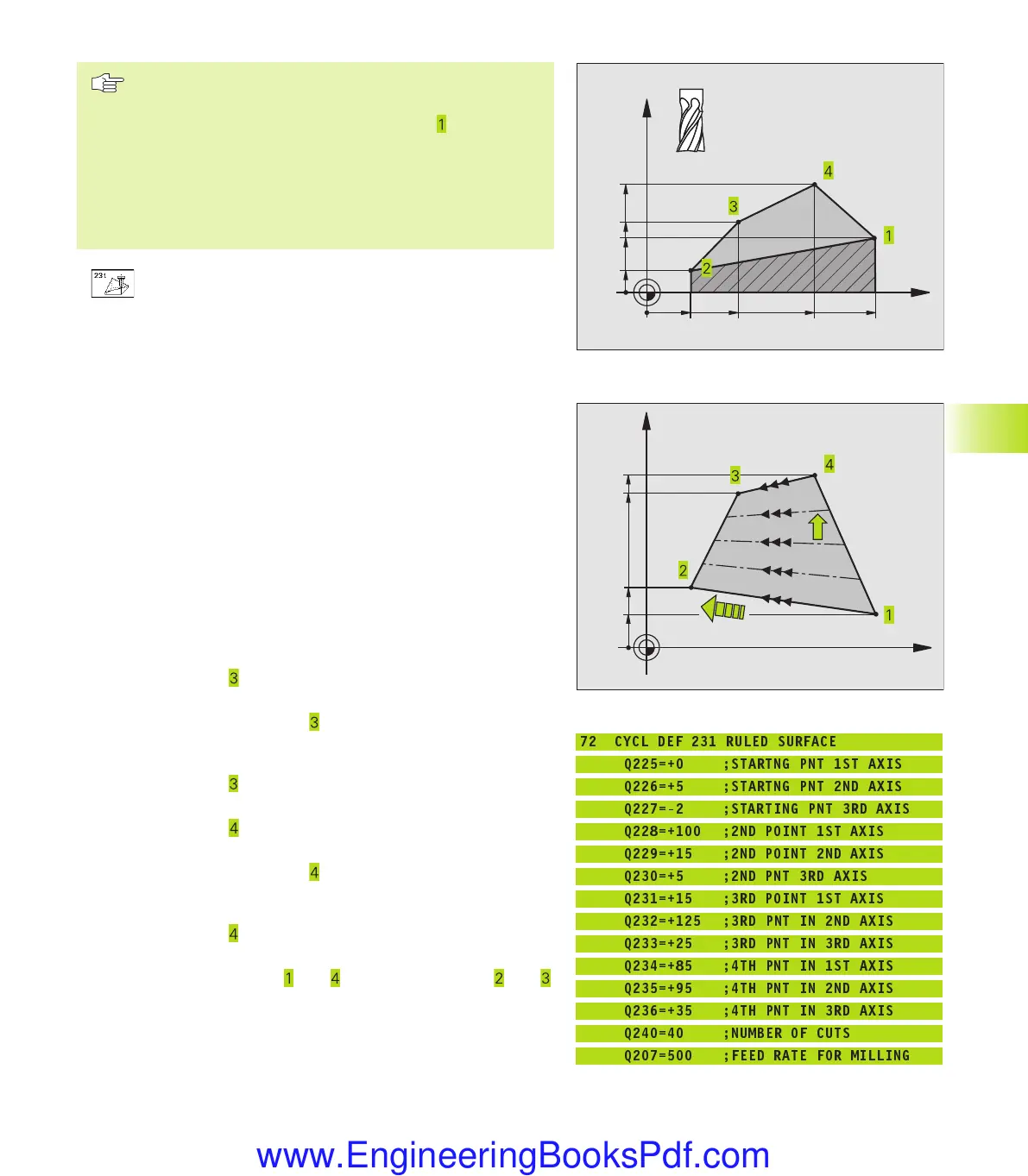

From the current position, the TNC positions the tool in a

linear 3-D movement to the starting point

. Pre-position

the tool in such a way that no collision between tool and

clamping devices can occur.

The TNC moves the tool with radius compensation R0 to

the programmed positions.

If required, use a center-cut end mill (ISO 1641).

ú

Starting point in 1st axis Q225 (absolute value):

Starting point coordinate of the surface to be

multipass-milled in the main axis of the working plane

ú

Starting point in 2nd axis Q226 (absolute value):

Starting point coordinate of the surface to be

multipass-milled in the secondary axis of the working

plane

ú

Starting point in 3rd axis Q227 (absolute value):

Starting point coordinate of the surface to be

multipass-milled in the tool axis

ú

2nd point in 1st axis Q228 (absolute value): Stopping

point coordinate of the surface to be multipass milled

in the main axis of the working plane

ú

2nd point in 2nd axis Q229 (absolute value): Stopping

point coordinate of the surface to be multipass milled

in the secondary axis of the working plane

ú

2nd point in 3rd axis Q230 (absolute value): Stopping

point coordinate of the surface to be multipass milled

in the tool axis

ú

3rd point in 1st axis Q231 (absolute value): Coordinate

of point in the main axis of the working plane

ú

3rd point in 2nd axis Q232 (absolute value):

Coordinate of point in the subordinate axis of the

working plane

ú

3rd point in 3rd axis Q233 (absolute value): Coordinate

of point in the tool axis

ú

4th point in 1st axis Q234 (absolute value): Coordinate

of point in the main axis of the working plane

ú

4th point in 2nd axis Q235 (absolute value):

Coordinate of point in the subordinate axis of the

working plane

ú

4th point in 3rd axis Q236 (absolute value): Coordinate

of point in the tool axis

ú

Number of cuts Q240: Number of passes to be made

between points and , and between points and

ú Feed rate for milling Q207: Traversing speed of the

tool in mm/min while milling. The TNC performs the

first step at half the programmed feed rate.

8.6 Cycles for Multipass Milling

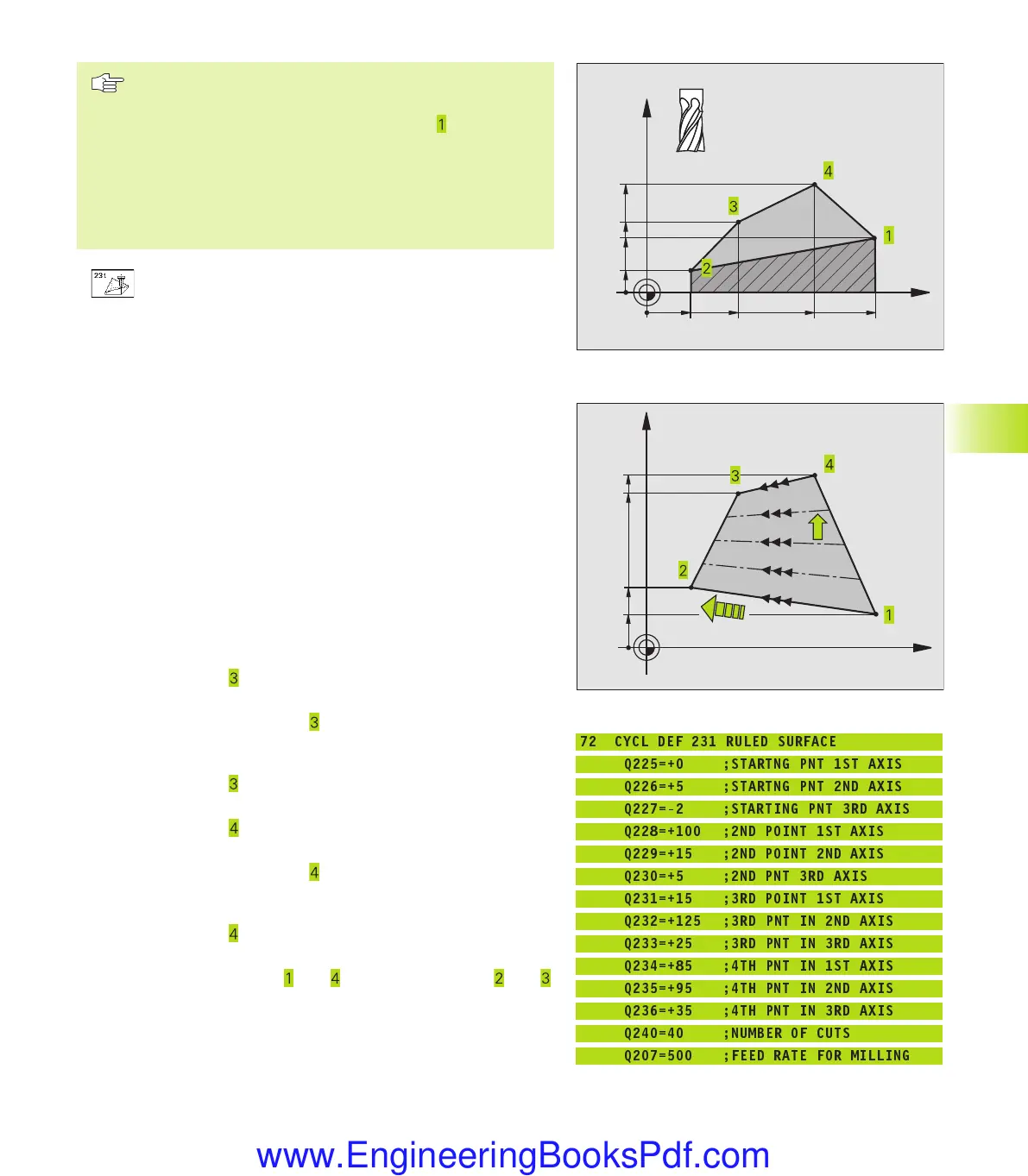

X

Y

Q229

Q207

N = Q240

Q226

Q232

Q235

X

Z

Q236

Q233

Q227

Q230

Q228 Q225Q234Q231

Example NC blocks:

72 CYCL DEF 231 RULED SURFACE

Q225=+0 ;STARTNG PNT 1ST AXIS

Q226=+5 ;STARTNG PNT 2ND AXIS

Q227=-2 ;STARTING PNT 3RD AXIS

Q228=+100 ;2ND POINT 1ST AXIS

Q229=+15 ;2ND POINT 2ND AXIS

Q230=+5 ;2ND PNT 3RD AXIS

Q231=+15 ;3RD POINT 1ST AXIS

Q232=+125 ;3RD PNT IN 2ND AXIS

Q233=+25 ;3RD PNT IN 3RD AXIS

Q234=+85 ;4TH PNT IN 1ST AXIS

Q235=+95 ;4TH PNT IN 2ND AXIS

Q236=+35 ;4TH PNT IN 3RD AXIS

Q240=40 ;NUMBER OF CUTS

Q207=500 ;FEED RATE FOR MILLING

kkap8.pm6 30.06.2006, 07:04217

www.EngineeringBooksPdf.com

Loading...

Loading...