70

5 Programming: Tools

5.2 Tool Data

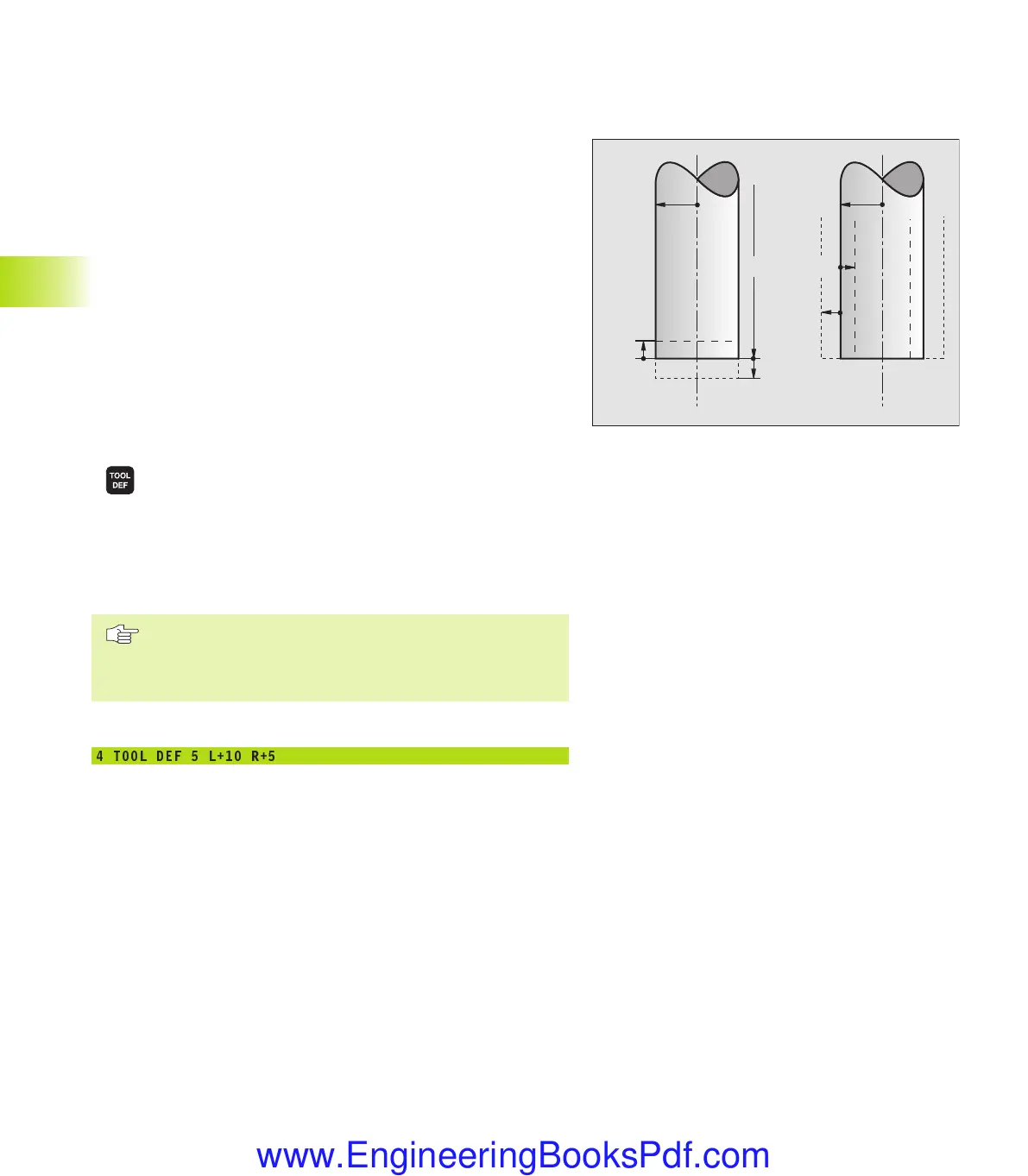

DR<0

DR>0

DL<0

R

DL>0

L

R

Tool radius R

You can enter the tool radius R directly.

Delta values for lengths and radii

Delta values are offsets in the length and radius of a tool.

A positive delta value describes a tool oversize (DL, DR, DR2>0). If

you are programming the machining data with an allowance, enter

the oversize value in the TOOL CALL block of the part program.

A negative delta value describes a tool undersize (DL, DR, DR2<0).

An undersize is entered in the tool table for wear.

Delta values are usually entered as numerical values. In a TOOL

CALL block, you can also assign the values to Q parameters.

Input range: You can enter a delta value with up to ± 99.999 mm.

Entering tool data into the program

The number, length and radius of a specific tool is defined in the

TOOL DEF block of the part program.

ú

To select tool definition, press the TOOL DEF key.

ú

Enter the Tool number: Each tool is uniquely identified

by its number.

ú

Enter the tool length: Enter the compensation value

for the tool length.

ú

Enter the Tool radius.

In the programming dialog, you can transfer the value for

tool length directly into the input line with the actual-

position-capture key. You only need to make sure that the

highlight in the status display is placed on the tool axis.

Resulting NC block:

4 TOOL DEF 5 L+10 R+5

Fkap5.pm6 30.06.2006, 07:0370

www.EngineeringBooksPdf.com

Loading...

Loading...