December 2001 What is a Machine Parameter? 4 – 3

4 Machine Parameters

4.1 What is a Machine Parameter?

A contouring control must have access to specific data (e.g., traverse

distances, acceleration) before it can execute its programmed instructions.

You define these data in machine parameters.

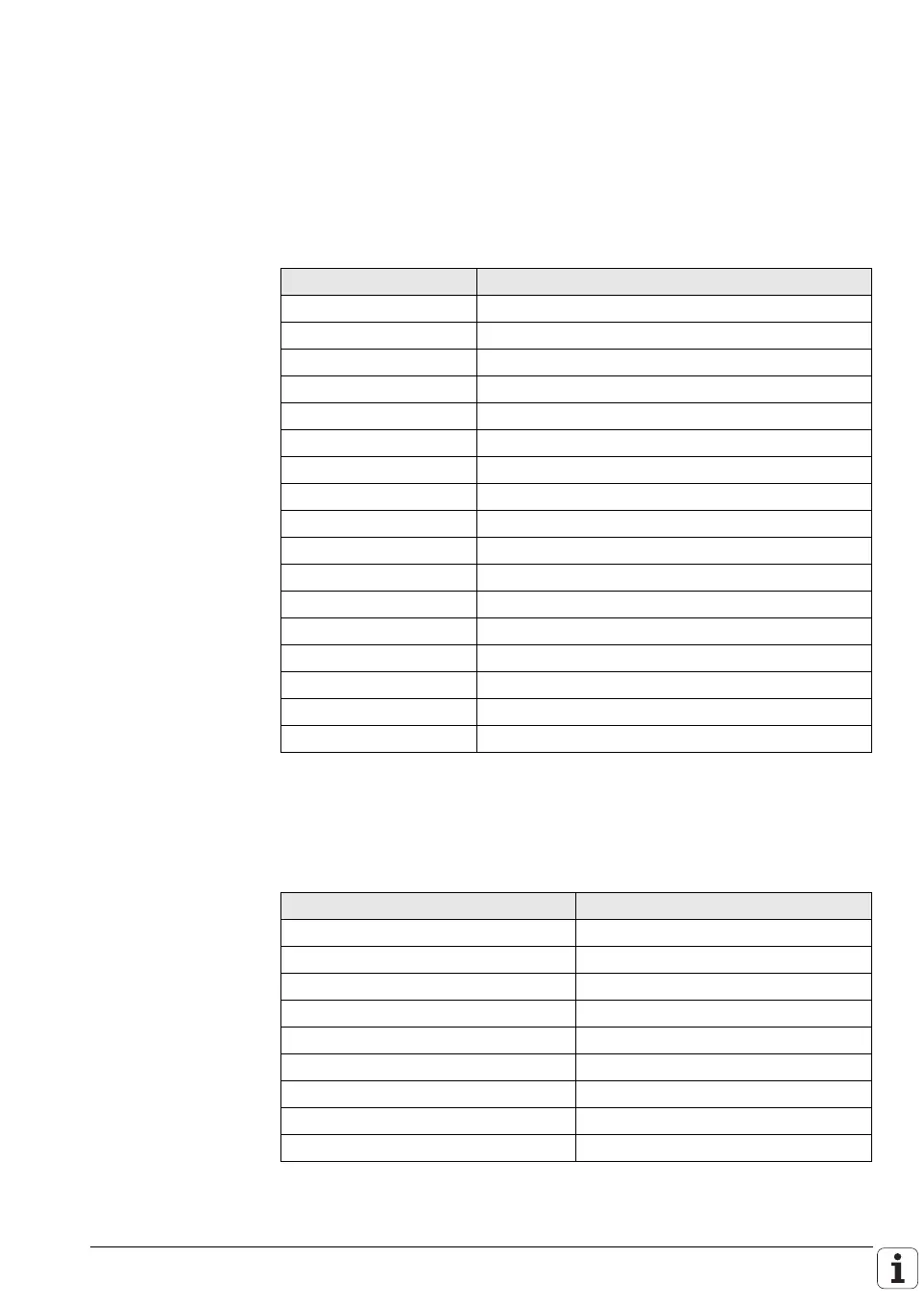

This list of machine parameters is divided into groups according to topic.

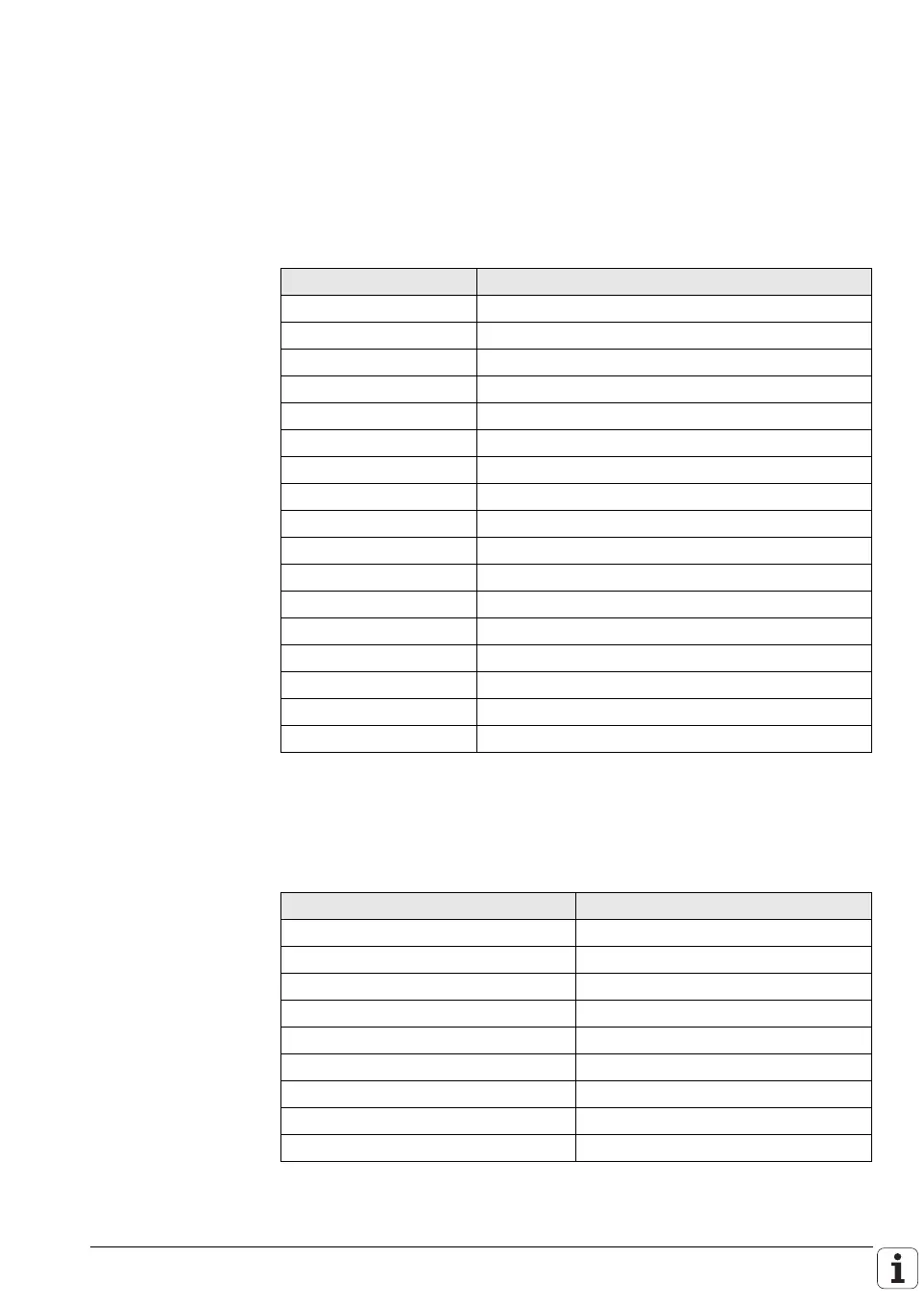

If there is more than one input value for a single function (e.g., a separate input

for each axis), the parameter number is extended by indices. Index zero is

always axis 1, index one is axis 2, etc.

Example:

Machine parameters Topics

10 to 999 Encoders and machines

1000 to 1399 Positioning

1400 to 1699 Operation with Velocity Feedforward Control

1700 to 1999 Operation with Following Error (Servo Lag)

2000 to 2999 Integrated Speed and Current Control

3000 to 3999 Spindle

4000 to 4999 Integral PLC

5000 to 5999 Data Interface

6000 to 6199 3-D touch probe

6200 to 6299 Digitizing with triggering touch probe

6300 to 6399 Digitizing with measuring touch probe

6500 to 6599 Tool measurement with triggering touch probe

7100 to 7199 Tapping

7200 to 7349 Programming and display

7350 to 7399 Colors

7400 to 7599 Machining and Program Run

7600 to 7699 Hardware

MP1010.0-8 Rapid traverse

MP1010.0 Rapid traverse for axis 1

MP1010.1 Rapid traverse for axis 2

MP1010.2 Rapid traverse for axis 3

MP1010.3 Rapid traverse for axis 4

MP1010.4 Rapid traverse for axis 5

MP1010.5 Rapid traverse for axis 6

MP1010.6 Rapid traverse for axis 7

MP1010.7 Rapid traverse for axis 8

MP1010.8 Rapid traverse for axis 9

Loading...

Loading...