23

Troubleshooting Guide

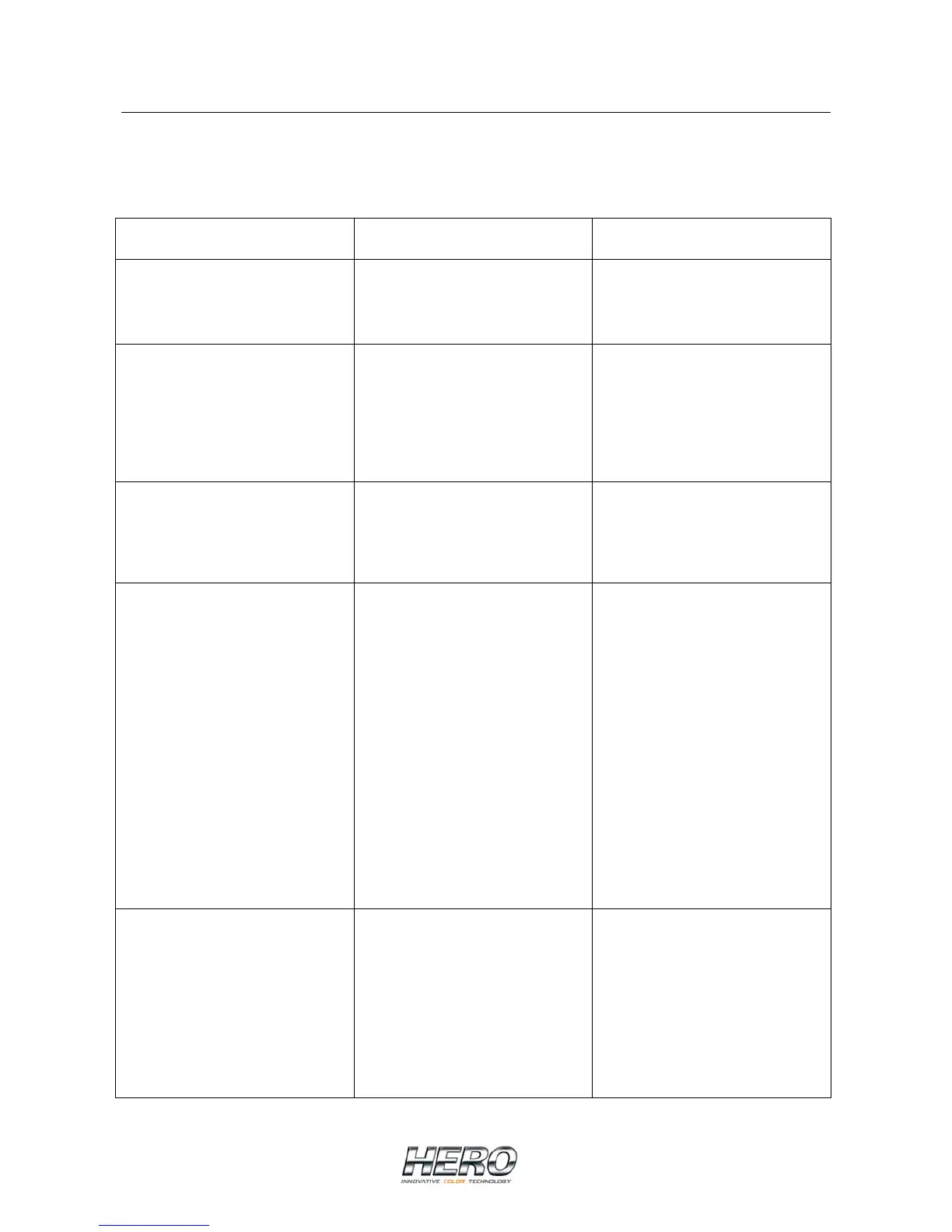

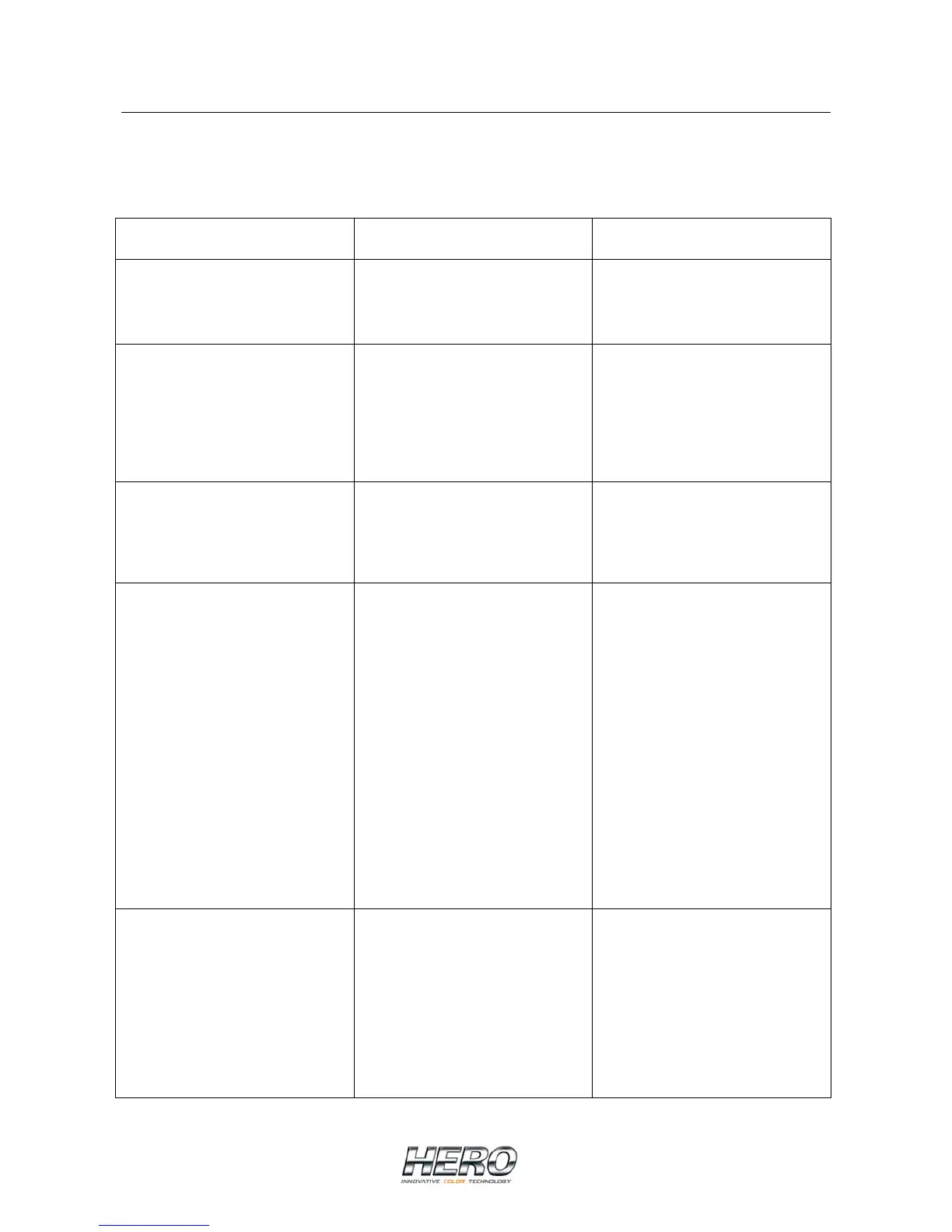

The following chart listing “Problem”, “Cause” and “Solution” should be consulted before

requesting service.

When in doubt, please contact HERO EUROPE S.r.l.’s service department before any

attempts are made to repair the equipment.

PROBLEM

CAUSE

SOLUTION

Colourant leaks from the flange

connecting the pump motor to the

canister

Broken pump

Canister replacement

Colourant dripping from the

nozzle

• Air in the circuit

• The pull-back function

parameters are not set

correctly

• Purge the circuit until you

see a regular colorant

flow, free from air bubbles

• Program the pull-back

function parameters

correctly

When dispensing ends the

colorant goes back towards the

canister through the nozzle thus

emptying the tubing

Worn pump

Canister replacement

During operation, the circuit

dispenses in a noisy, irregular

way

• The cable connecting the

electronic card and the

pump motor is not

plugged in correctly

• The cable connecting the

electronic card and the

pump motor is damaged

• Motor has broken down

• Electronic card is not

working

• Stalled pump

• Check that the cable

between the electronic

card and the motor is

properly connected on

both ends

• Replace the cable

connecting the electronic

card and the motor

• Replace the canister

• Replace the electronic

card

• Start the pump by hand

slowly until it unblocks.

Increase the purging

frequency and if

necessary, thin the

colourant

The sensors don’t work

and/or

The pump motors don’t work

and/or

The mixing motors don’t work

The connection between the PC

and the machine is no longer

functioning

• No power

• The machine’s power

cable is disconnected

• The power cable for the

electronic card is not

plugged in

• A fuse has blown

• Verify that the unit has

power

• Connect the machine’s

power cable to the power

outlet

• Make sure the power

cable to the electronic

card is plugged in

• Replace the fuse

Loading...

Loading...