Maintenance

e

Wa

挝

te

町

d

怡

1

怡

eak

,阳

ag

伊

Star! the engioe and check that 00 water

leaks from the joints between Ihe. exhaust

cover

, cylinder head, and body cylinder

EM

U

四

"。

Engine

oilleakage

Check for oilleaks on the around Ihe engine.

NOTE:

1I

any leaks are found, consult your dealer.

Checking

prope

lJ

er

,帽

You

could

be

seriously

injured

if

the en-

gine

accidentally starts when

you

are

near the propeller.

• Before inspecting

, removirig,

or

install-

ing

the

propeller, remove the

spark

plug

caps

from the

spark

plugs.

Also

,

place

the

shift

control

In

neutral,

turn

the

main

switch

to

"OFF" (off)

and

re-

move

the

key

,

and

remove the lanyard

from the engine stop switch. Turn

off

the battery

cut-off

switch

if

your

boat

has

one

.

•

00

not

use yoUr hand

to

hold

the

pro-

peller when loosenlng

or

tightening

the

propeller

nu

t.

Put a

wood

block

be-

tween

the

anti-cavitation plate

and

the

propeller

to

prevent the propeller

from

turning.

39

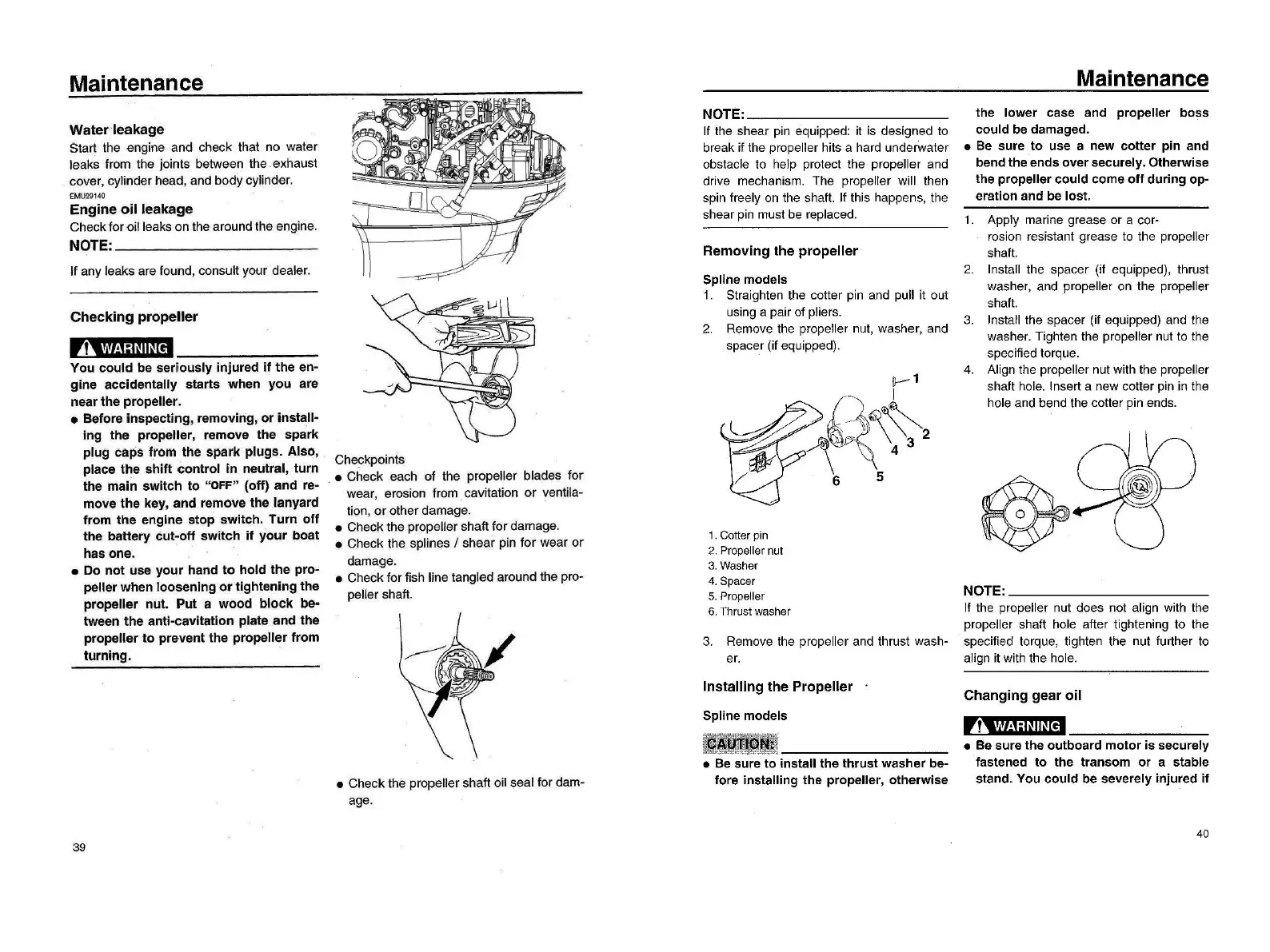

Checkpoints

• Check each of the propeller blades for

wear, erosion from cavitation

or

ventila-

tion,

or

other damage.

• Check the propeller shaft for damage.

• Check the splines / shear pin for wear

or

damage.

• Check for fish line tangled around the pro-

pe"er shaft

• Check the prope"er shaft oil seal for dam-

age

NOTE:

If Ihe shear pin equipped: il

is

designed to

break if Ihe propeller hils a hard underwaler

obslacle

10

help prolecl the propeller and

drive mechanism. The propeller will then

spin freely on the shaf

t.

If Ihis happens, the

shear

pin

must be replaced.

Re

町、

oving

the

propeller

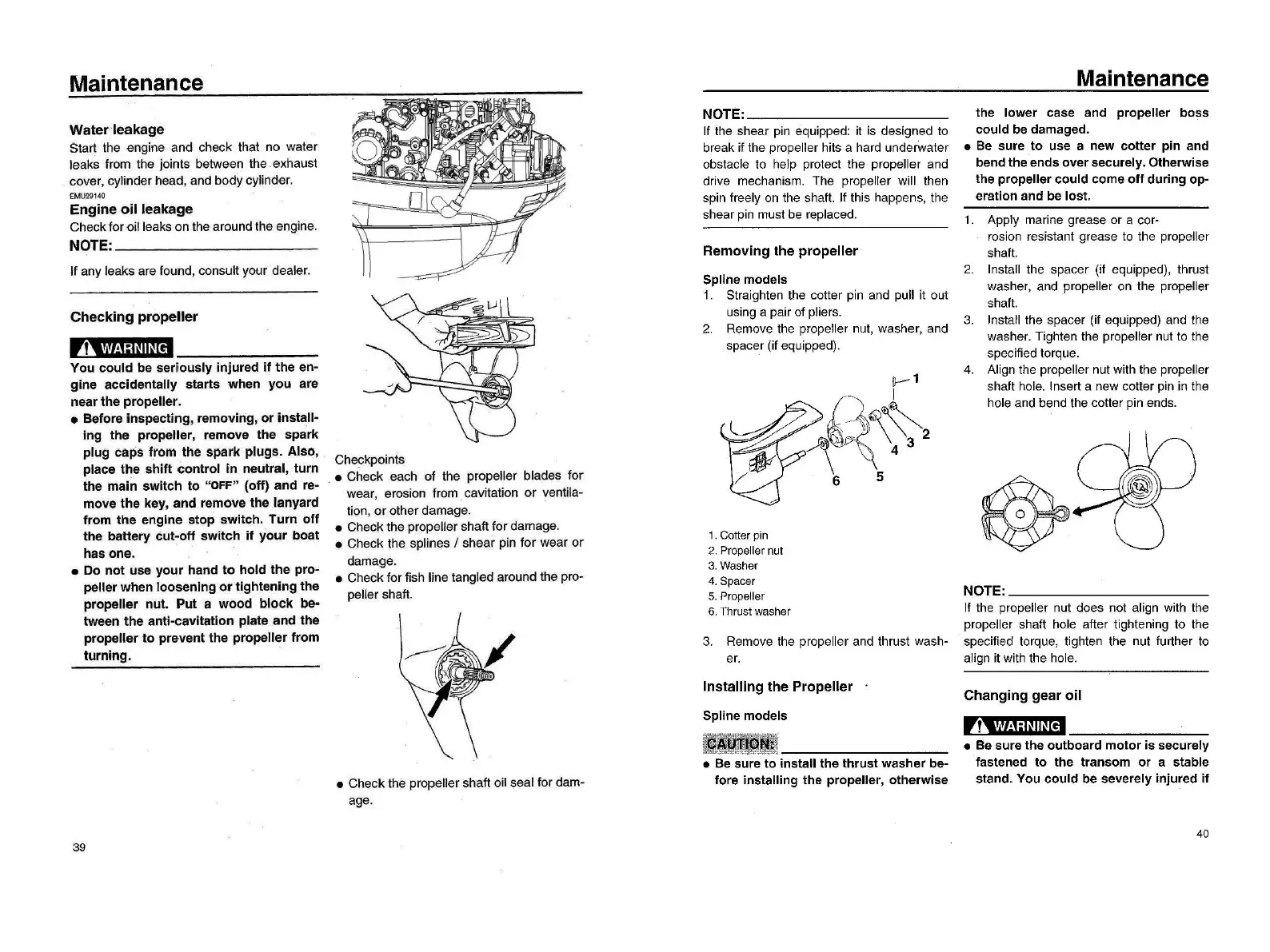

Spline models

1.

Straighten the cotter pin

and

pull it out

using a pair of pliers.

2.

Remove the propeller nut, washer, and

spacer (if equipped).

1.

Cotterpin

2.

Propeller

nut

3.

Washer

4.

Spacer

5.

Propeller

6.

Thrust

washer

3.

Remove the propeller

and

thrust wash-

自『

Installing

the

Propeller

Spline models

Maintenance

the lower case and propeller boss

could be damaged.

• Be sure

to

use a new cotter

pin

and

bend the ends over securely. Otherwise

the propeller could come

off

during

Op-

eration and be

los

t.

1.

Apply marine grease or a cor-

rosion resislanl grease

10

Ihe propeller

shaft

2.

Insta" the spacer (if equipped), thrusl

washer

, and propeller

on

the prope"er

shaf

t.

3.

Insta" the spacer (if equipped) and the

washe

r.

Tighten the prope"er nut

10

the

specified torque.

4.

Align the prope"er nut with the prope"er

shaft hole. Insert a new cotter pin

in

the

hole and bend the

co

忧

er

pin

ends

NOTE:

If the prope"er nut d

Ci

es not align with the

prope"er shaft hole after tightening

10

the

specified torque, tighlen the nut

fu

r!her

10

align it with Ihe hole

Changing

gear

oil

,?‘

.'1'1

土

.':I~II~rl

帽

麟意麟

iii

-Besu

陀

the

outboard

motor

is

…肉

• Be sure

to

install the

thrust

washer be- fastened

to

the transom

or

a stable

fore installing the propeller, otherwise stand. You

could

be severely injured

if

40

Loading...

Loading...