L300P Supplement Explanation of functions

3.Standard specification list

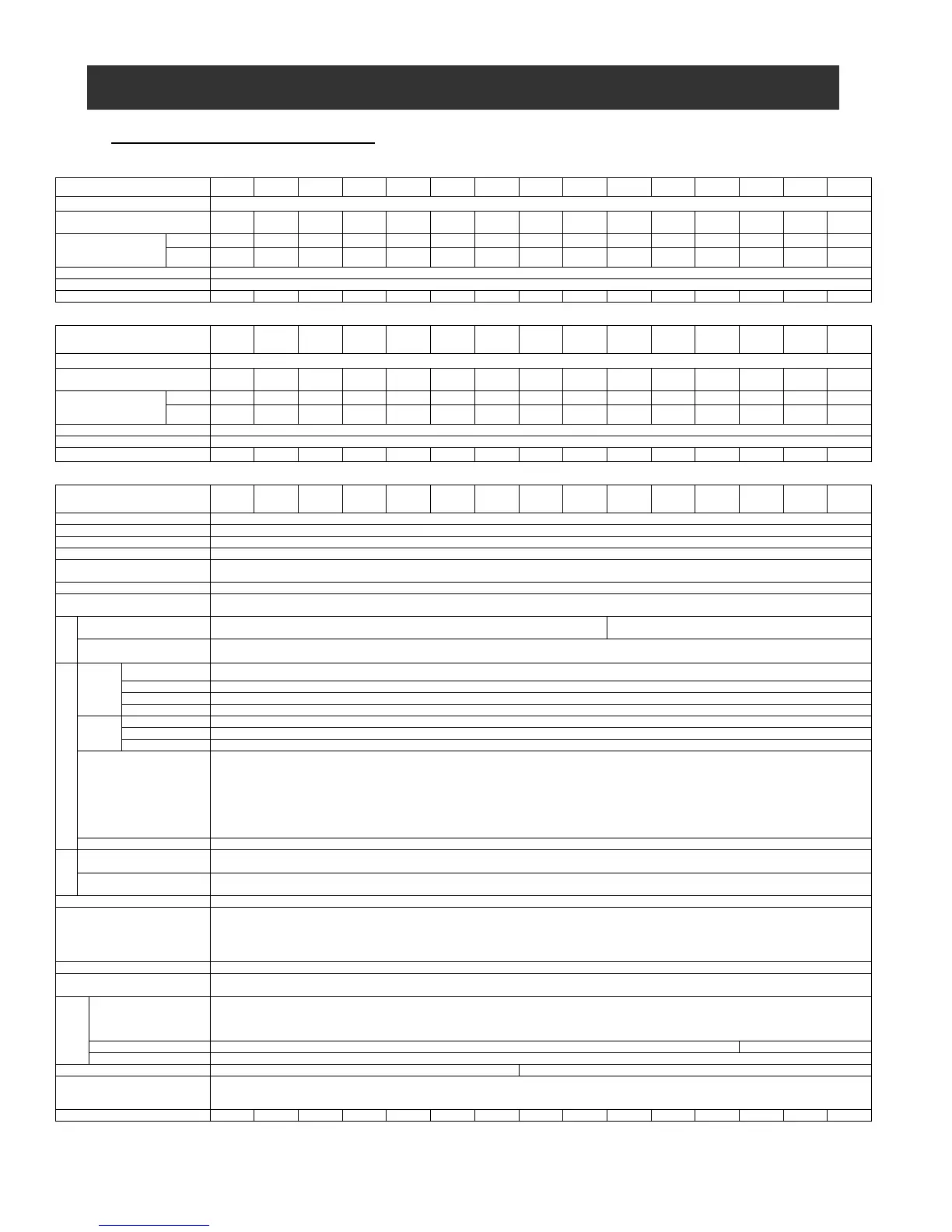

(1) 200V class

Inverter Model

L300P-

004LFU

L300P-

007LFU

L300P-

015LFU

L300P-

022LFU

L300P-

037LFU

L300P-

055LFU

L300P-

075LFU

L300P-

110LFU

L300P-

150LFU

L300P-

185LFU

L300P-

220LFU

L300P-

300LFU

L300P-

370LFU

L300P-

450LFU

L300P-

550LFU

Protection structure (note1)

IP20(NEMA1)

Max. Applicadie Motor 4P (kW)

(note2)

0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

200V

1.0 1.5 2.5 3.6 5.7 8.3 11.0 15.2 20.0 25.2 29.4 39.1 48.4 58.5 72.7

Rated input

Alternating

voltage(kVA)

240V

1.2 2.0 3.1 4.3 6.8 9.9 13.3 18.2 24.1 30.3 35.3 46.9 58.1 70.2 87.2

Rated input alternating voltage Three-phase 200-240V (+-10%) 50Hz/60Hz

Rated output voltage (note3) Three-phase 200-240V (This corresponds to receiving voltage.)

Rated output current (A)

3 5 7.5 10.5 16.5 24 32 44 58 73 85 113 140 169 210

(2) 400V class

Inverter Model

-

L300P-

007HF

U

L300P-

015HF

U

L300P-

022HF

U

L300P-

037HF

U

L300P-

055HF

U

L300P-

075HF

U

L300P-

110HFU

L300P-

150HF

U

L300P-

185HF

U

L300P-

220HF

U

L300P-

300HF

U

L300P-

370HF

U

L300P-

450HF

U

L300P-

550HF

U

Protection structure (note1)

IP20(NEMA1)

Max. Applicadie Motor 4P (kW)

(note2)

-

0.75 0.15 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

400V

-

1.5 2.5 3.6 5.7 8.3 11.0 15.2 20.0 25.6 29.7 39.4 48.4 58.8 72.7

Rated input

Alternating

voltage(kVA)

480V

-

2.0 3.1 4.3 6.8 9.9 13.3 18.2 24.1 30.7 35.7 47.3 58.1 70.1 87.2

Rated input alternating voltage Three-phase 380-480V (+-10%) 50Hz/60Hz

Rated output voltage (note3) Three-phase 380-480V (This corresponds to receiving voltage.)

Rated output current (A)

-

2.5 3.8 5.3 8.6 12 16 22 29 37 43 57 70 85 105

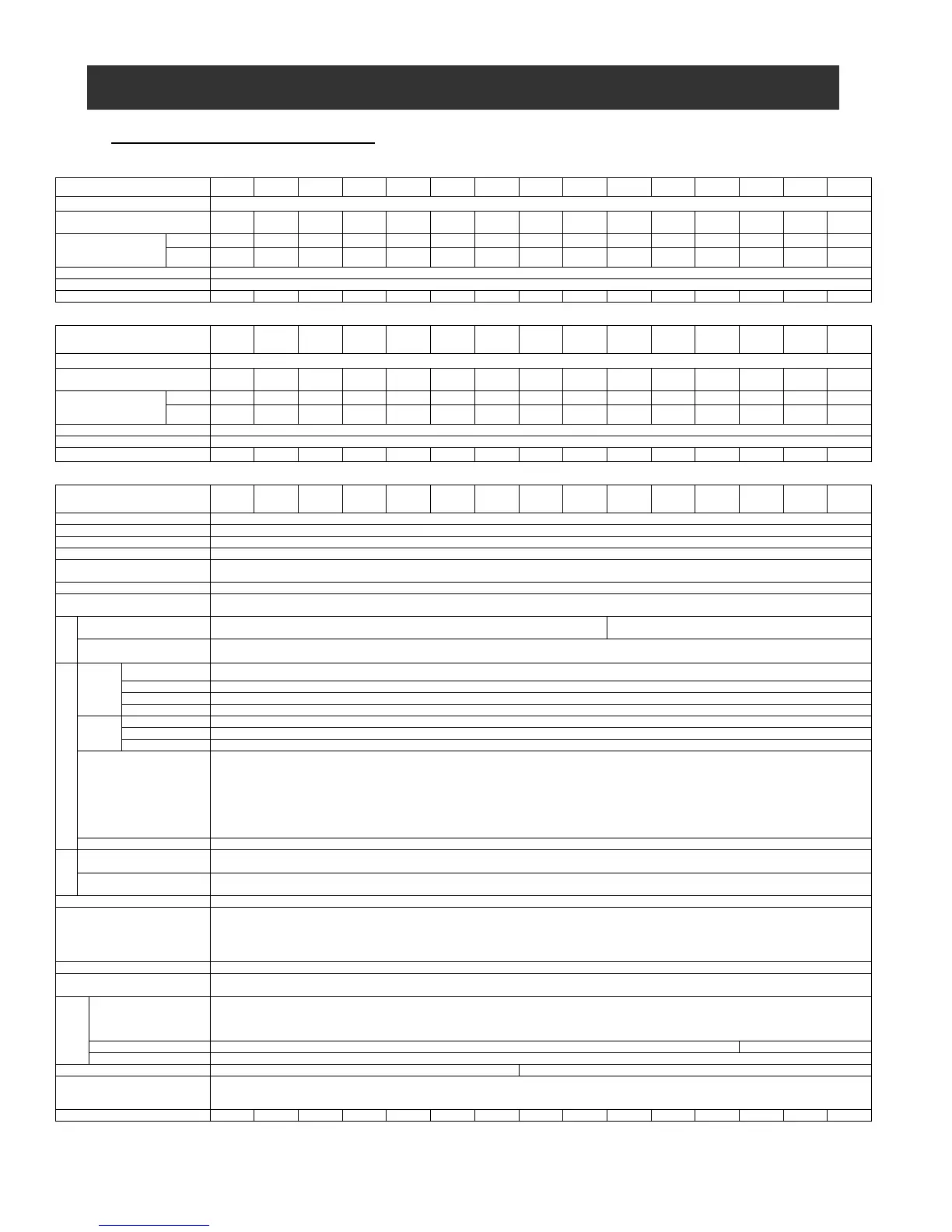

(3) Commom specification for 200V/400V class

Inverter Model

L300P-

004

LFU

L300P-

007

L/HFU

L300P-

015

L/HFU

L300P-

022

L/HFU

L300P-

037

L/HFU

L300P-

055

L/HFU

L300P-

075

L/HFU

L300P-

110

L/HFU

L300P-

150

L/HFU

L300P-

185

L/HFU

L300P-

220

L/HFU

L300P-

300

L/HFU

L300P-

370

L/HFU

L300P-

450

L/HFU

L300P-

550

L/HFU

Control system Sine-wave modulation PWM system.

Output frequency range (note4) 0.1-400Hz

Frequency accuracy Digital command +/-0.01% for Max. frequency, analog frequency +/-0.2%(25+-10C)

Frequency resolving power Digital setting: 0.01Hz, analog setting:Max. frequency /4000

Voltage/frequency

characteristic

V/f option variable, V/f control, (constant torque, reduced torque)

Overload current rate 120% for 60 seconds, 150% for 0.5second

Acceleration/

deceleration time

0.01-3,600seconds (straight or S-Curve on acceleration, deceleration is optional setting individually), 2

nd

adjustable setting is possible.

Regenerative Control

(short duration) (note5)

BRD circuit built-in

(Discharge resistance is required.)

Regenerative unit is required.

Contro

DC Braking

On starting and decelerating by stop command, inverter operates under operation setting frequency. Or inverter operates with external input

(Breaking power, time, frequency can be set.)

Operator

No Operator

Volum e

Setting with potentiometer on the digital operator (Built-in as standard) (Analog setting)

External Signal

DC 0 to 5V, -5 to +5V, 0 to 10V, -10 to +10V (input impedance 10k ohm), 4-20mA (input impedance 100 ohm)

Freq-

uency

External port

Setting with RS485 communication

Operator

No Operator

External signal

Forward Run/Stop (1a connect), reverse command is impossible on assigning of terminal (selection of 1a, 1b is possible), input of 3 wires is possible.

Run/

Stop

External port

Setting with RS485.

Intelligent input

terminal

Use by selecting terminals from;

Reverse command (RV), multi-speed1-4 (CF1-CF4), jogging (JG), external dc braking (DB), 2

nd

control (SET),2

nd

acceleration (2CH), free-run stop (FRS),

external trip (EXT),

USP function (USP), commercial change (CS),software lock (SFT), analog input voltage / current / select (AT), reset inverter (RS), 3 wire run (STA),3 wire

keep (STP),

3 wire direction selection (F/R), PID selection valid/invalid (PID), PID integrating reset (PIDC), remote control,up function (UP), remote control down function

(DWN),

remote control data clear (UDC), multi-speed bit 1-7(SF1-SF7),overload ristriction change (OLR), permissive input signal for FW/RV(ROK), no assign (NO)

Input signal

Thermistor input t erminal 1 terminal

In

ter

telligent output

minal

2 relay outputs (1a contact), relay(1c contact), output relay selection as follows;

(selection from during running, on arrival with constant speed, over setting frequency, PID over-deviation, running command distinction)

Output

Intelligent monitor

output terminal

Analog voltage output, analog current output, pulse line output

Display monitor Output frequency, output current, frequency conversion value, trip history, input output terminal state, input electric power, output voltage.

Other function

V/f free setting (5 points), Upper / lower frequency limitter, Frequency jump, Curve adjustable speed, Manual torque boost level / Braking point,Analog meter

adjustment,

Starting frequency, Carrier frequency adjustment, Electronic thermal free setting, External start/end (frequency/rate),Analog input selection, Trip retry,

Reduced voltage start,

Overload restriction

Carrier frequency range 0.5-12 kHz

Protection function

Over-current, over-voltage, under-voltage, electronic thermal level, abnormal trouble, ground fault current on starting, instantaneous stop, USP error,

open-phase error, control resistor overload, CT error, external trip, communication error

Frequency temperature

/Preservation

temperature

(note6) /humidty

-10 to 40 degrees (note7) / -20 to 65 degrees / 20 to 90% RH (installed with no dew condensation)

Vibration (note7) 5.9m

/ s

2

(0.6G), 10-55Hz 2.9m

/ s

2

(0.3G), 10-55Hz

Usage

surrounding

Using place Under 1,000m above sea level, indoors (installed away from corrosive gasses, dust)(note8)

Paint color Grey ( Munsell 8.5YR6.2 / 0.2 ) Blue (D.I.C14 version No.436)

Options

Remote operator, copy unit, cable for each operator, braking resistor, regenerative control unit, alternating reactor, D.C. reactor, EMC Mains filter, higher

harmonic

control unit, LCR filter, applied control installation

3.5 3.5 3.5 3.5 3.5 3.5 5 5 5 12 12 12 20 30 30 Schematic mass (kg)

(note1) Protective system bases on JME1030.

12

Loading...

Loading...