108

10. CAUTIONS FOR A LONG TERM OPERATION SUSPENSION

CAUTION

● If the air compressor stops for a week or more without taking action described in this page, serious

damage for the airend may occur due to the lack of lubrication or airend internal rusting.

● Use unload stop button not only for long operation suspension but also for daily operation to prevent

the airend from the rusting.

● If the air compressor can’t be operated weekly, rust prevented action and periodical inspection is

required. Contact the local HITACHI distributor/master dealer or representative office for the detail.

UP/

DOWN

+/-

AUTO

MONITOR

MENU

SET

SELECT/WIDE

2

RUNNINGCONTROL

STARTREMOTE

1

FUNC

[×10h]

ALARM

STR

REMOTE

RUNNINGMODE

AUTOSTART

POWER

LOAD

RESET

SHUTDOWN

STOP

MONITOR

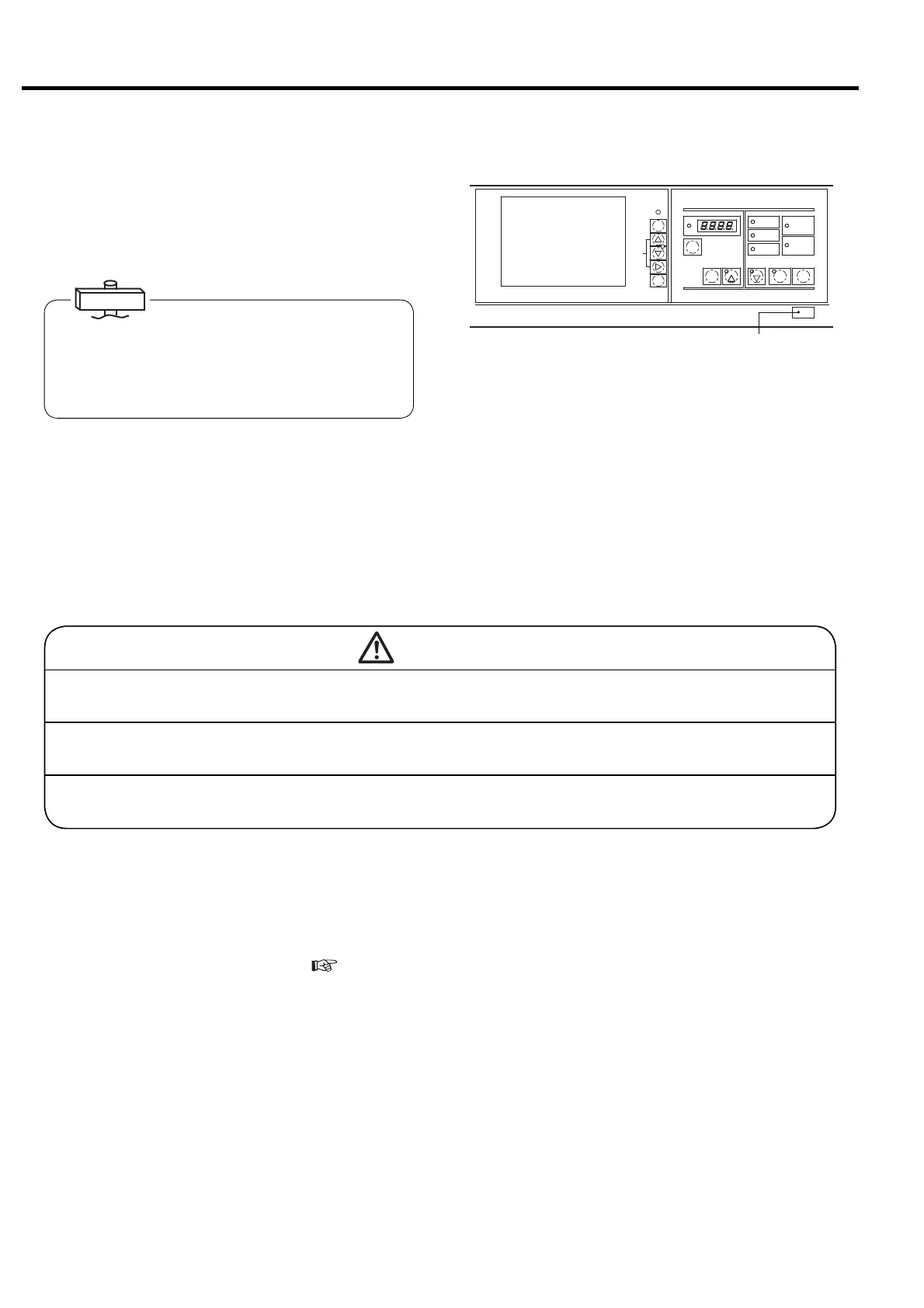

UNLOAD STOP button

UNLOAD STOP

■ How to perform the unload stop action with

lead-lag or multi unit control operation (option)

Unload stop button is ineffective when the operation

mode setting is NOT “Single”. (

3.3.5 )

Deactivate the lead-lag or multi unit control at once

and perform unload stop. When the air compressor is

restarted, set the operation setting to required mode.

① If the compressor is not to be used for a week or

more, be sure to press the UNLOAD STOP button on

the instrument panel.

The compressor then unloads for 5 minutes and

automatically stops when the airend and the piping

are dry.

② To prevent the inside of airend from rusting, press the

UNLOAD STOP button and dry the compressor for 5

- 10 minutes a week.

③ Be sure to turn off the power if the compressor is not

to be used for an extended period of time.

If unloading is executed before the compressor is stopped,

moisture will be removed from the second-stage air end.

To prevent the second-stage air end from rusting during a

long-time suspension, it is effective to dry the inside of the

air end before stopping the compressor..

IMPORTANT

Loading...

Loading...