45

5. INSTALLING AND PIPING THE DSP [Piping the DSP Air Compressor]

・ This is to prevent the reciprocating compressor's air

pulsation from affecting this air compressor.

・ Typical operation is to run this air compressor as long

as possible as the primary and start, and stop the

reciprocating air compressor in parallel as a floating

trim air compressor, as required by the compressed air

demand.

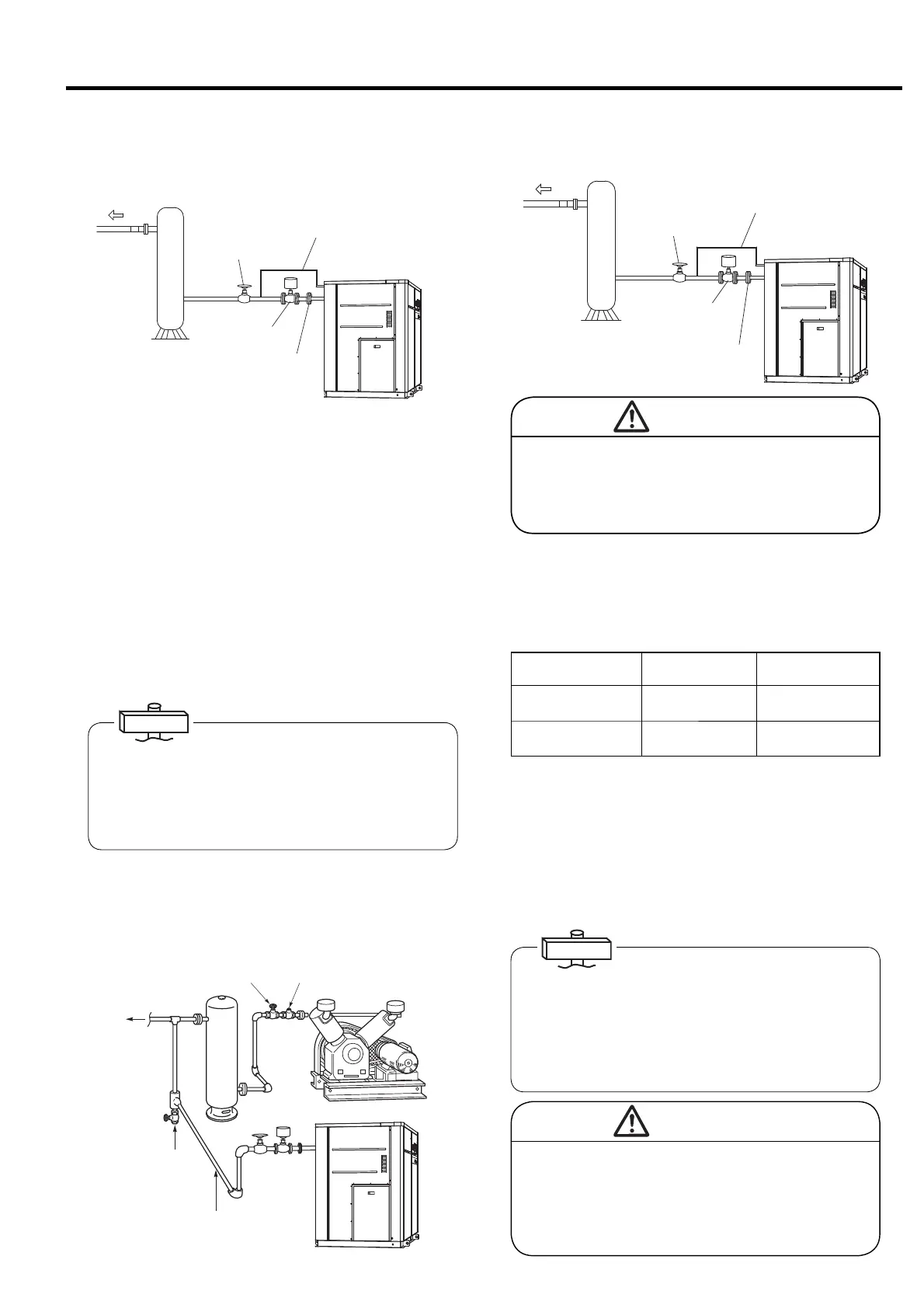

①

Install the air receiver tank because this air

compressor is equipped with 2-step capacity control

system. To prevent the pressure fluctuation and to

maximize the energy saving feature, the minimum size

of the air receiver tank is indicated in the table blow.

5.4.5 Air Receiver Tank

② Install the air receiver tank of 620 USgal (2.26m

3

) of

more for the

AUTO operation, multi-unit control or

lead/lag operation in order to achieve the better energy

saving effect.

③ Install the air receiver tank of 620 USgal (2.26m

3

)of

more for using ECOMODE in order to achieve the

better energy saving effect on all load ratio.

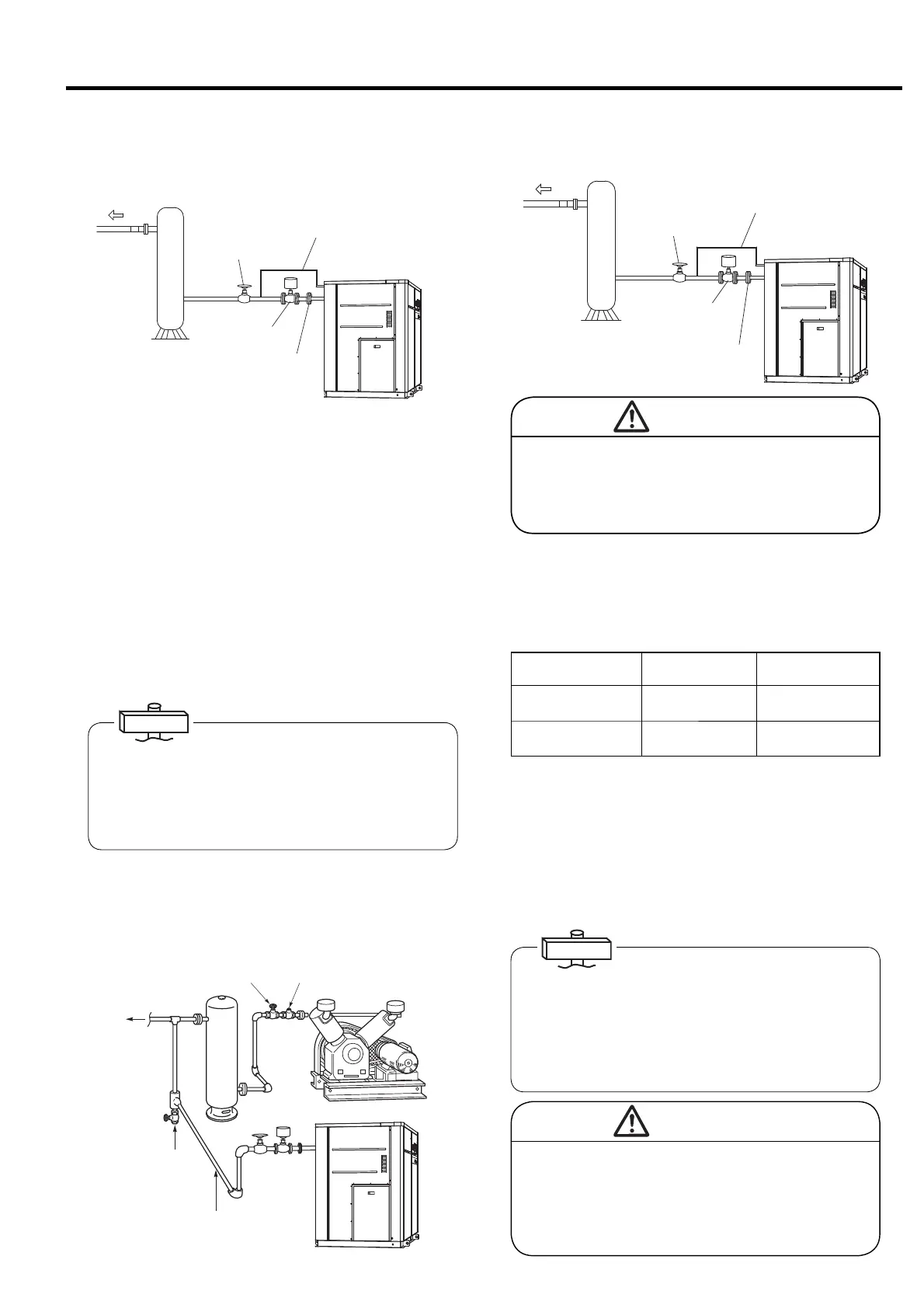

Pressure detecting piping

Discharge

air

Stop valve

Flange

Motorized

isolation valve

Air receiver tank

5.4.4 Reciprocating Compressor and

Parallel Piping

Check valveStop valve

Discharge air

Stop valve

Piping to air receiver

tank outlet

Model

Discharge pressure

psi (MPa)

Minimum capacity of

air receiver tank (m

3

)

DSP-45/55/75ATN

DSP-45/55/75WTN

100/125

(0.69/0.86)

620 USgal (2.26)

DSP-55/75VATN

DSP-55/75VWTN

100/125

(0.69/0.86)

400 USgal (1.24)

CAUTION

Do not install a check valve between this air

compressor and the air receiver tank. This

could result in short cycling (frequent loading

and unloading) and operating problems to the

capacity control system.

5.4.3 How to Install Automatic

Discharge Valve

The air compressor is equipped with AUTO restart/stop

function as a standard function. The pressure for

capacity control is detected at the secondary side of the

motorized isolation valve. Install the motorized isolation

valve and pressure detecting piping (standard accessory).

Connect the pressure detecting piping from upper side of

main piping to pressure detecting port of the air

compressor as above.

Install the pressure detecting piping as close as

motorized isolation valve. The operation with NOT

installed pressure detecting piping results in the relief

valve action.

Motorized

isolation

valve

Discharge

air

Stop valve

Flange

Pressure detecting piping

Air receiver tank

The motorized isolation valve is closed when the air

compressor is stops. The operation WITHOUT the

motorized isolation valve results in the backflow of

condensate from the plant compressed air system. Then

it results in the early damage of check valve, aftercooler

and etc by rusting

IMPORTANT

IMPORTANT

Failure to install an adequately sized air

receiver tank may cause the air compressor to

frequently load/unload. This may shorten the

mechanical life of the air compressor.

CAUTION

Loading...

Loading...