79

8. STANDARD COMPONENTS AND SUBSYSTEMS [Capacity Control System]

Pressure

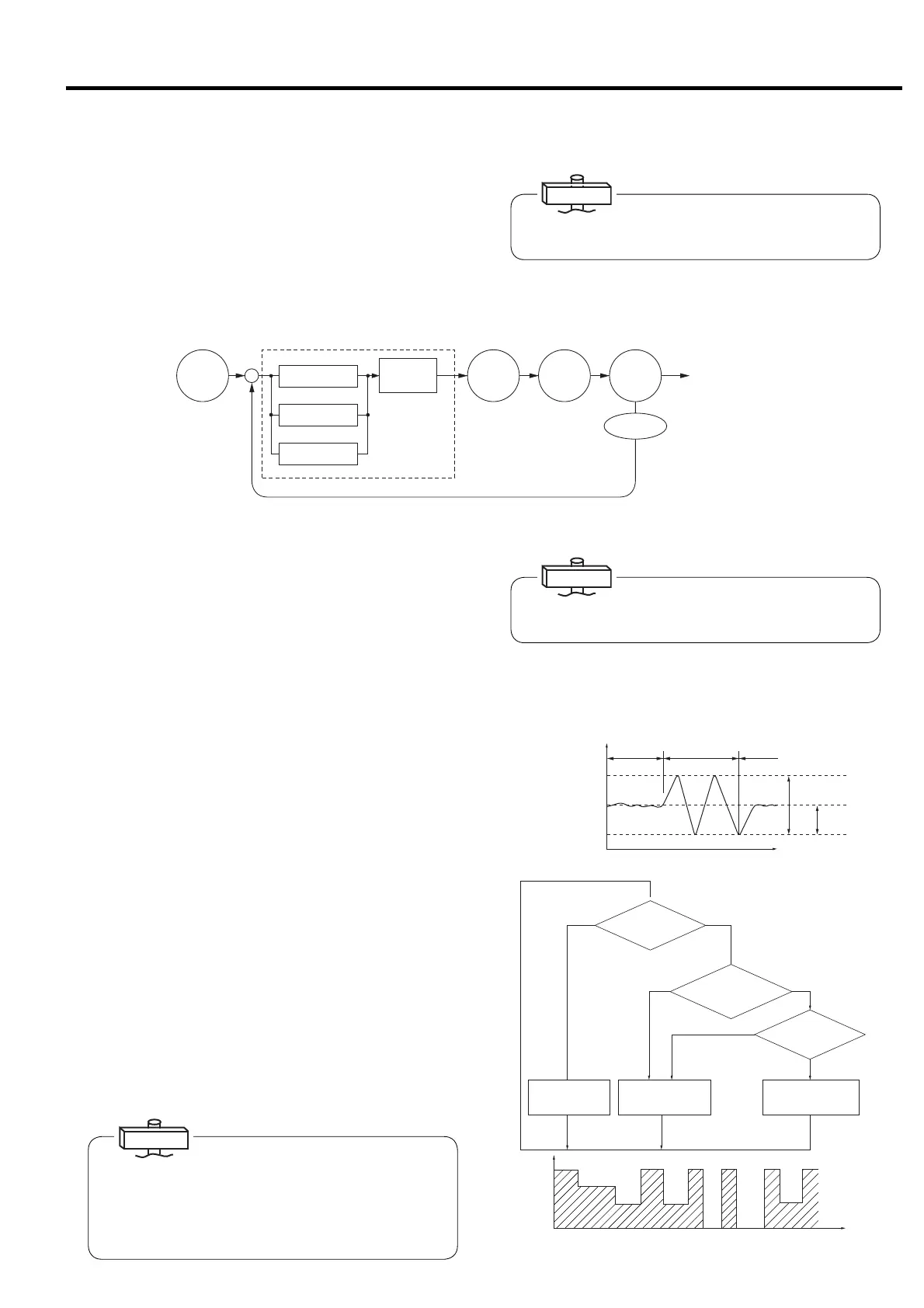

CPCS Motor Speed Control by Inverter and CPU

P: proportional

I : integral

D: differential

Inverter

Motor

DSP

Compressed

air

Pressure sensor

Constant Pressure

of the Discharge Air

PID stands for Proportional, Integral, and Differential.

CPCS stands for Constant Pressure Control System.

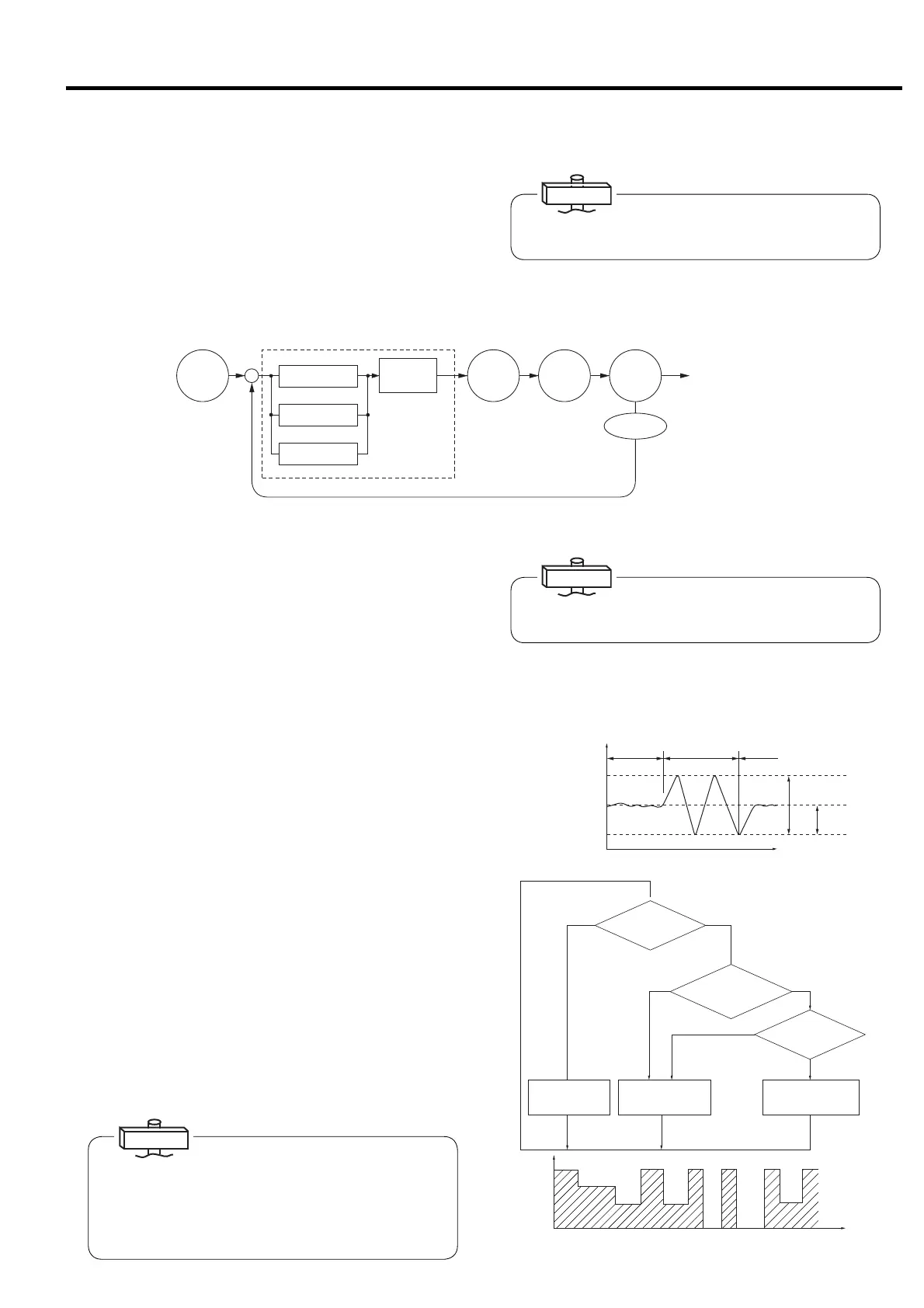

The differential range between the Cut-out pressure and

the Cut-in pressure must be 7 psi (0.05 MPa) or more.

①

②

①

Time

Pressure

Minimum

7psi

Minimum

1psi

Cut-in Pressure

Control Pressure

Cut-out Pressure

① ②

③

①

② ②

③ ③

②

100

0

The values are for air-cooled, 75 kW, 100 psi (0.69 MPa) type.

Q>50%

or

Hz>78

Operation Frequency Hz

(Q≦45%)

Q≦5%

or

T≧3 minutes

Air Consumption Q

or

Purging Time T

Number of

Motor Stopping N

(for 10 minutes

)

Q>5%

or

T<3 minutes

CPCS Motor

Speed Control

Two-Step Purge

Start/Stop Control

Motor Stop/Restart

Control

N≦1

Air Consumption

Q (%)

N>1

Q

≦

50%

or

Hz≦78

(1) Once the motor has stopped, it cannot restart for 15

seconds.

(2) The plant’s system pressure may drop drastically

before the motor restarts, 15 seconds later. To avoid

such problems, install an air receiver tank of 400 USgal

(1.24 m

3

) or larger.

IMPORTANT

IMPORTANT

IMPORTANT

① CPCS Motor Speed Control

Based on the pressure signals detected by the pressure

sensor, the built in circuit board’s CPU performs PID

operations or calculates the motor speed that meets the

compressed air consumption rate, and then inputs the

calculated results to the inverter. The inverter outputs

the instructions of the corresponding frequency to the

motor. The discharge pressure is controlled within a

targeted range due to the increasing and decreasing

speeds of the motor.

② Two-Step Purge Control

Two-Step Purge Control is activated if the following

conditions occur at the same time.

・The operating frequency drops to 78 Hz (equivalent to

50% of the air consumption).

・The pressure detected by the pressure sensor rises to

a cut-out (purge-start) pressure.

The blowoff solenoid valve (1) operates to start purging

the compressed air (contained between the airend and

the check valve) to atmosphere. The system decreases

the operating frequency to its lowest operating

frequency, 66 Hz, thus saving power. When the pressure

detected by the pressure sensor drops to a cut-in (purge-

stop) pressure, the system increases the frequency to 78

Hz and the blowoff solenoid valve (1) operates to stop

the purging, returning the system control back to CPCS

Motor Speed Control.

(Air-cooled 75 kW/100 psi (0.69MPa) Types)

③ Motor Stop/Restart Control

Motor Stop/Restart Control is activated under one of the

following conditions.

・Air consumption decreases to 5 %

・Purge operating continues for 3 minutes.

The system then automatically stops the motor. For

protection, the motor can only be stopped once every 10

operating minutes. When the pressure detected by the

pressure sensor drops to a cut-out (purge-stop) pressure,

the system automatically restarts the motor, returning

the system control to CPCS Motor Speed Control.

Loading...

Loading...