User Manual Installation, Assembly and Commissioning

EM1 Series AC Servo Motors EM1-01-0-EN-2110-MA Page 42 of 72

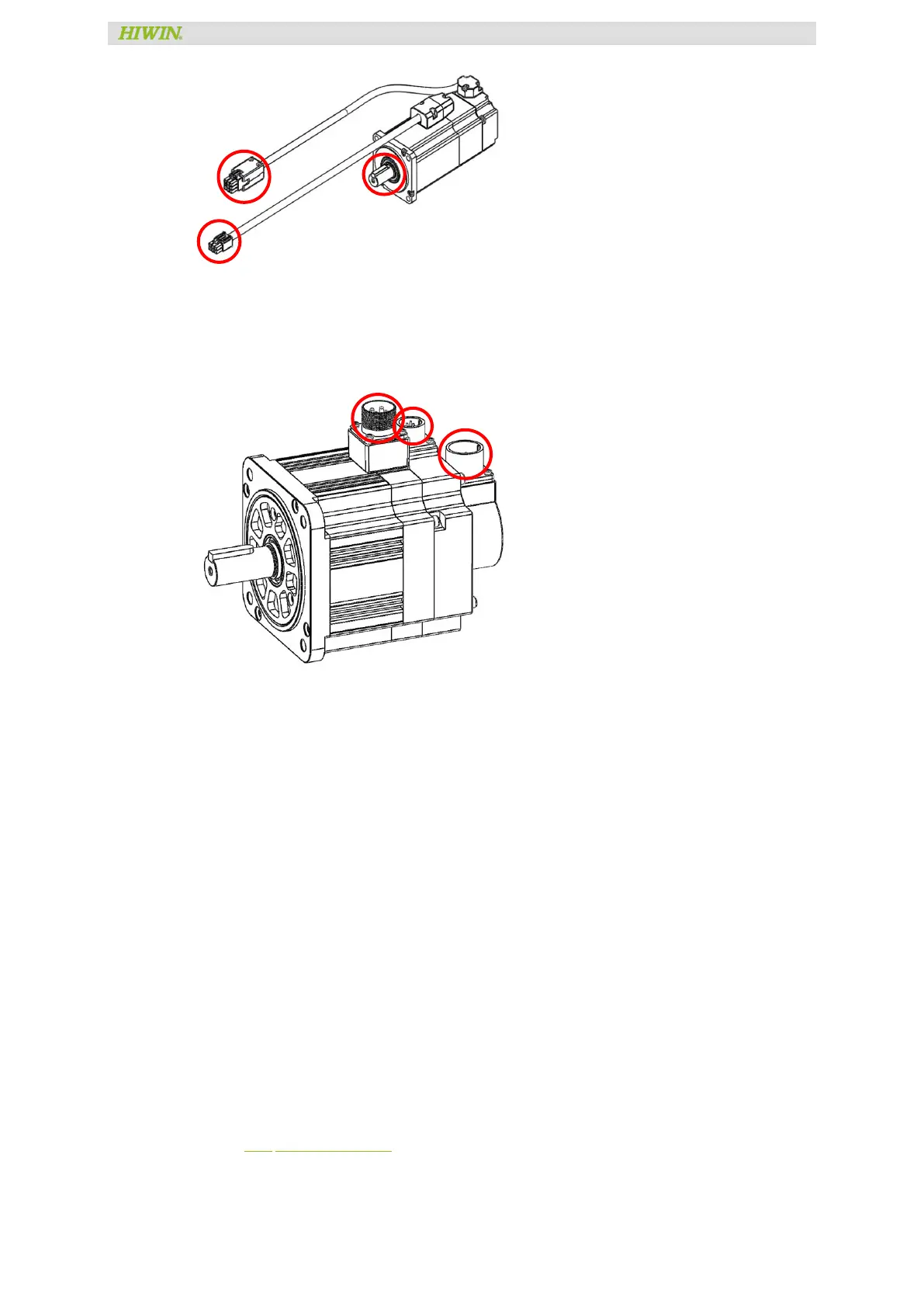

– 1 kW to 2 kW: IP65

For 1 kW to 2 kW servo motors, the protective structure specifications can only be satisfied

when military connector connecting with cable.

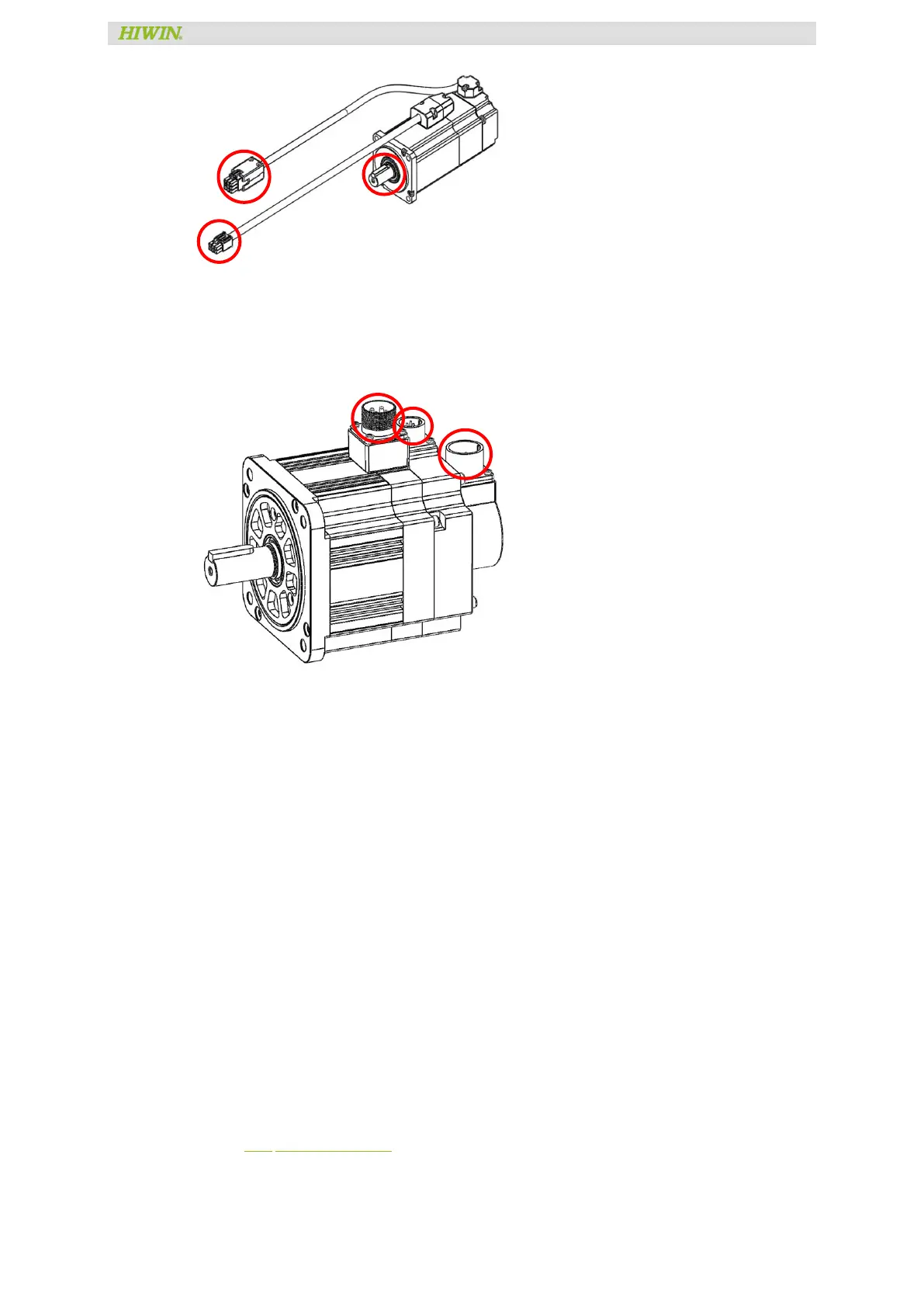

Motor through shaft section need to add oil seal which is optional for all type of AC servo

motor.

Preparation

Prepare motor assembly as following instructions:

1. Procure tools, supplies, measuring and test equipment.

2. Check all components for visible damage. Damaged components may not be

mounted.

3. Ensure that dimensions and tolerances on the system side are suitable for motor

attachment (for details, see the dimension sheet).

4. Inspect all components, mounting surfaces and threads to ensure they are clean.

5. Make sure that the assembly can be carried out in a dry and dust-free environment.

6. Make sure that the holder for the motor flange is deburred.

7. Remove the protective sleeve of the motor drive shaft and keep it for further use.

Assembly

Assemble the motor and observe that:

1. Avoid pinching or jamming the centering collar on the motor side.

2. Avoid damage to the insertion fitting on the system side.

3. Connect the motor with the machine and observe the tightening torques.

4. Check whether the connection is firm and accurate before carrying out any further

steps.

After having assembled the motor mechanically, prepare it for electrical connection. (See

Chapter 8.2.3 Electrical Connection

)

Loading...

Loading...