OPERATION

HOLZMANN Maschinen GmbH www.holzmann-maschinen.at Seite 22

Drechselbank / wood turning lathe D 460FXL

13.2 Electrical connection

DANGER

When working on a non-earthed machine:

Severe injuries from electric shock in case of malfunction possible!

Therefore:

Machine must be grounded and be connected to a grounded outlet.

14 OPERATION

14.1 Before Operation

Before starting check the correct fit of moving parts.

Check that the workpiece is clamped correctly.

When the material to be machined to foreign matter such as Wires, nails, etc as well as irregu-

larities in the material such as knots.

Check whether the movable parts function perfectly and do not stick or whether parts are

damaged. All parts must be fitted correctly and fulfill all conditions to ensure the proper opera-

tion.

Turn each before turning by hand to ensure the clamped workpiece that it runs freely and the

palm rest is not affected.

You here Check also that the workpiece was clamped as centered as possible! The machine has

0.5 horsepower and a weight of 33kg. Unbalanced clamped and non-centric workpieces can

quickly lead to strong vibrations during operation.

Put your editing tools never expire on the machine bed. Check before switching on whether

there are any tools, etc. are on the machine bed.

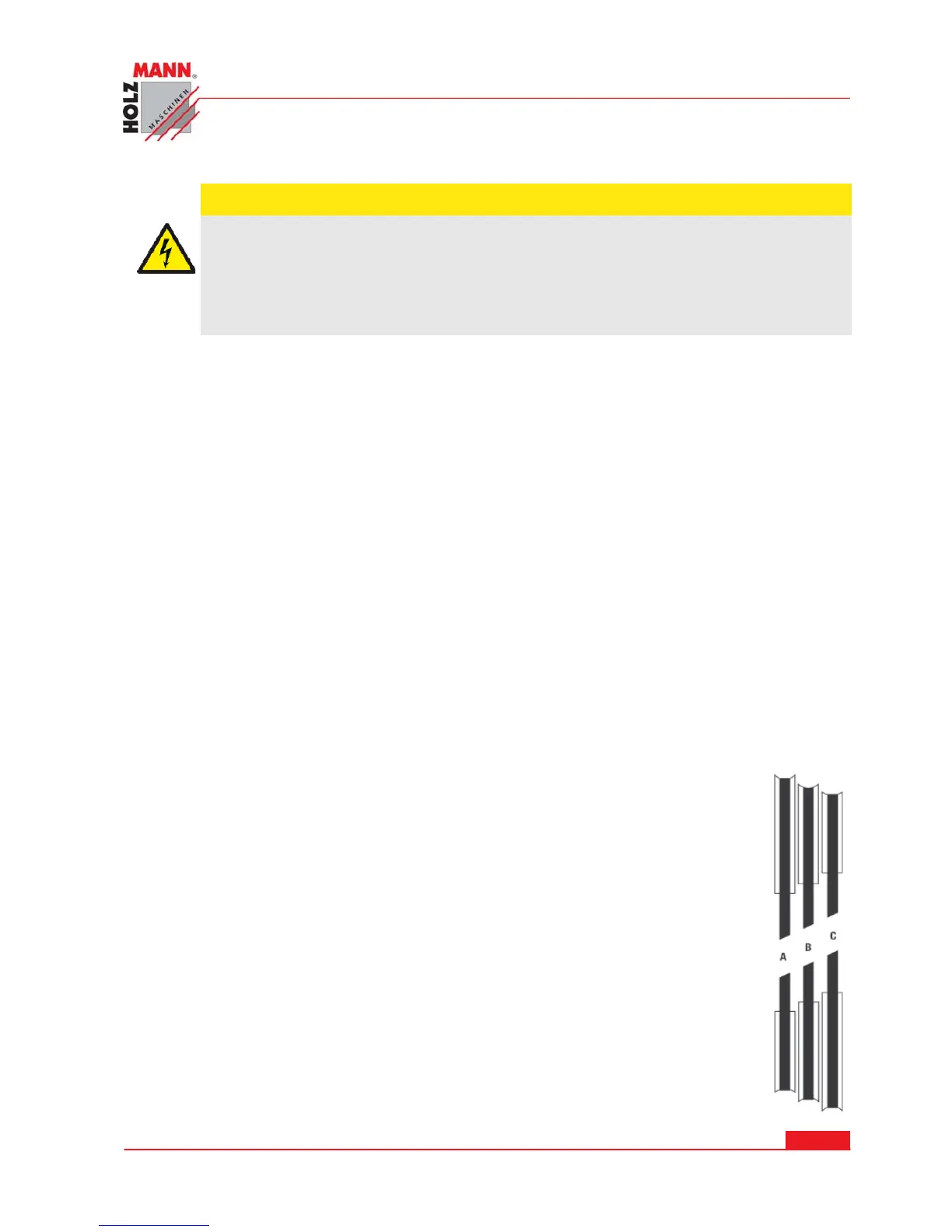

14.2 Wahl der Geschwindigkeit

When D 460FXL the speed by moving the belt must be adjusted according to the

picture. To do this, open the cover behind the headstock to obtain access to the belt

pulleys and place the belt accordingly. Relax the Transmission belt is explained in

section 8.3.

When D 460FXL they can speed through the potentiometer, positioned on the head-

stock, easily adjusted continuously via the rotary knob.

Low speeds must be used for:

Coarse roughing the workpiece / rough machining / the workpiece is to bring in a

centric form / is unbalanced - to to minimize vibration.

To avoid with large workpieces to high centrifugal forces.

High speed must be used for:

When waxing, grinding, during boring.

The smaller and centric, the workpiece, the greater may be the speed.

A: 650 - 1430 min

-1

B: 1240 - 2790 min

-1

C: 1600 - 3800 min

-1

Loading...

Loading...