Flex 402 & Flex 404 Instruction Manual — P/N 52194:D4 3/27/2015 47

Appendix A: NFPA Standard-Specific Requirements

The Flex 402 and Flex 404 have been designed for use in commercial, industrial, and institutional

applications and meet the requirements for service under the National Fire Protection Association

(NFPA) Standards outlined in this Appendix. The minimum system components required for

compliance with the appropriate NFPA standard are listed below:

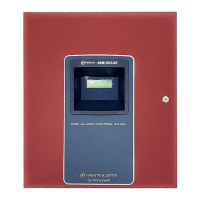

Flex 402/Flex 404 Control Panel

Contains the main control board, cabinet (backbox and door), main power supply transformer, and

power supply.

Batteries

Refer to “Power Supply Calculations” on page 43, for Standby Power Requirements.

Initiating Devices

Connected to one of the control panel's Initiating Device Circuits.

Notification Appliances

Connected to the control panel's Notification Appliance Circuits via a control module.

A.1 Central Station/Remote Station Transmitter: Connection

to FACP Dry Contacts

The dry contacts of the FACP programmable relays can be used to trip a UL-864 Listed Central

Station/Remote Station Transmitter. The FACP contacts must be supervised by the Central

Station/Remote Station Transmitter module using End-of-Line Resistors (ELRs) with a value

determined by the Transmitter manufacturer. Power is also provided by the Central Station/Remote

Station Transmitter manufacturer. Refer to the Central Station/Remote Station Transmitter

manufacturer’s manual for details.

B+ B- B+ B-

ZONE 1 ZONE 2

B+ B- B+ B-

ZONE 3 ZONE 4

C TRBL NORM

TROUBLE

C NC NO

ALARM SUPV

C NC NO

JP3

Figure A.1 FACP Dry Contacts Connection to Central Station/Remote Station Transmitter

Typical Central Station/Remote Station Transmitter Module

Typical Input Zone Triggers

FACP Main Circuit Board

Alarm

Trouble*

Supervisory

*Note: The Trouble Relay is a

fail-safe relay. With power

applied to the FACP and no

troubles in the panel, the wiring

should be connected to the C

and TRBL contacts as indicated

in the illustration.

ms4cdryxmit.wmf

Loading...

Loading...