GB-7

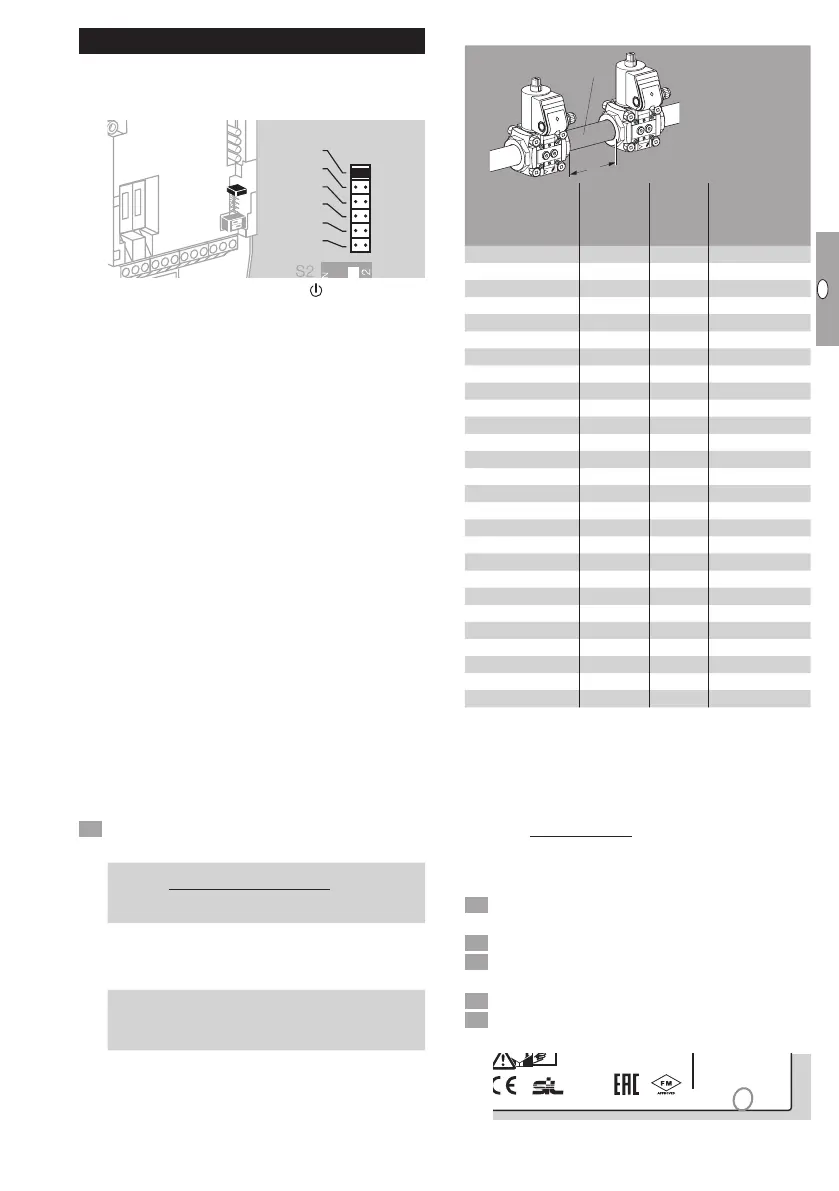

Setting measurement time t

M

▷

The measurement time t

M

can be set with a

jumper in increments of 5s to max. 30s.

▷ t

M

is set to 30s at the factory.

M

5s

10s

15s

20s

25s

30s

▷

No jumper: no function. The

LED is perma-

nently red, see page 8 (Assistance in the

event of malfunction).

▷

The longer the measurement timet

M

, the greater

the sensitivity of the tightness control. The longer

the measurement time, the smaller the leakage

rate at which a safety shut-down/fault lock-out

is triggered.

▷

For all CG versions, the measurement

timet

M

must be set to 5s on TC1C.

▷ If no leakage rate is specified, we recommend

the max. measurement time is set.

▷

Within the scope of the European Union, the

maximum leakage rate Q

L

is 0.1% of the maxi-

mum flow rate Q

max.

[m

3

/h (n)].

▷ If a leakage rate is specified, find the measure-

ment timet

M

from the following:

Q

max.

= max. flow rate [m

3

/h]

Q

L

= Q

max.

[m

3

/h] x 0.1% = leakage rate [ l/h]

p

u

= inlet pressure [mbar]

V

P

= test volume [ l ], see page7 (Values for

valve and pipe volume)

▷

The tightness control TC requires a minimum

start rate in order to carry out tightness tests

on slow opening valves:

up to 5l (1.3gal) test volume V

P

= 5% of maxi-

mum flow rateQ

max.

, up to 12l (3.12gal) test

volume V

P

= 10% of maximum flow rateQ

max.

.

Determine measurement time t

M

.

▷ Measurement times t

M

for V1 and V2:

t

M

[s] =

2.5 x p

u

[mbar] x V

P

[ l ]

Q

L

[ l /h]

▷

The entire test period is made up of the meas-

urement timest

M

of both valves and the fixed

opening timet

L

of both valves together:

t

P

[s] = 2 x t

L

+ 2 x t

M

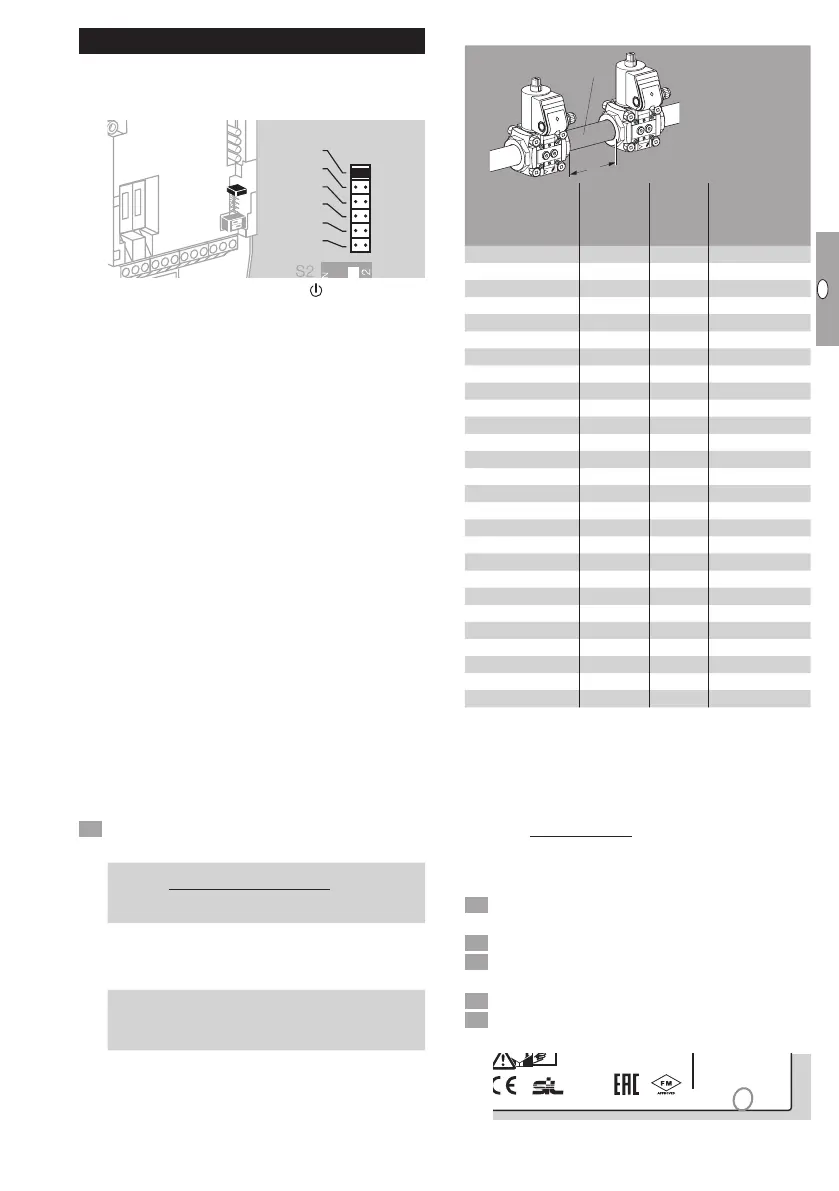

Values for valve and pipe volume

L

V

P

= V

V

+ L x V

V

P

V1

V2

Valves

Valve

volume

V

V

[ l ]

Nomi-

nal size

DN

Pipe

volume V

R

[ l/m]

VG 10 0.01 10 0.1

VG 15 0.07 15 0.2

VG 20 0.12 20 0.3

VG 25 0.2 25 0.5

VG 40/VK 40 0.7 40 1.3

VG 50/VK 50 1.2 50 2

VG 65/VK 65 2 65 3.3

VG 80/VK 80 4 80 5

VG 100/VK 100 8.3 100 7.9

VK 125 13.6 125 12.3

VK 150 20 150 17.7

VK 200 42 200 31.4

VK 250 66 250 49

VAS 1 0.08

VAS 2 0.32

VAS 3 0.68

VAS 6 1.37

VAS 7 2.04

VAS 8 3.34

VAS 9 5.41

VCS 1 0.05

VCS 2 0.18

VCS 3 0.39

VCS 6 1.11

VCS 7 1.40

VCS 8 2.82

VCS 9 4.34

Calculation example:

Q

max.

= 100 m

3

/h

p

u

= 100 mbar

V

P

= V

V

+ L x V

R

= 7 l

Q

L

= 100 m

3

/h x 0.1% = 100 l/h

2.5 x 100 x 7

= 17.5 s

100

Set the next highest value (in this example 20s)

with the jumper.

Disconnect the unit from the electrical power

supply.

Unscrew the housing cover.

4 Set the jumper to the position for the required

measurement time.

5 Position the housing cover and screw tight.

6 Mark the set measurement timet

M

on the type

label with a waterproof pen.

TC

D-49018 Osnabrück, Germany

t

M

(s) 5 10 15 20 25 30

▷ The entire test period for this example is as fol-

lows: 2 x 3 s + 2 x 20 s = 46 s.

Loading...

Loading...