GB-8

7 Switch on the power supply.

▷

The

LED flashes yellow (0.2 s on/off). After

10s, the TC accepts the new setting and

is

yellow or green, see table on page 8 (Com-

missioning).

Commissioning

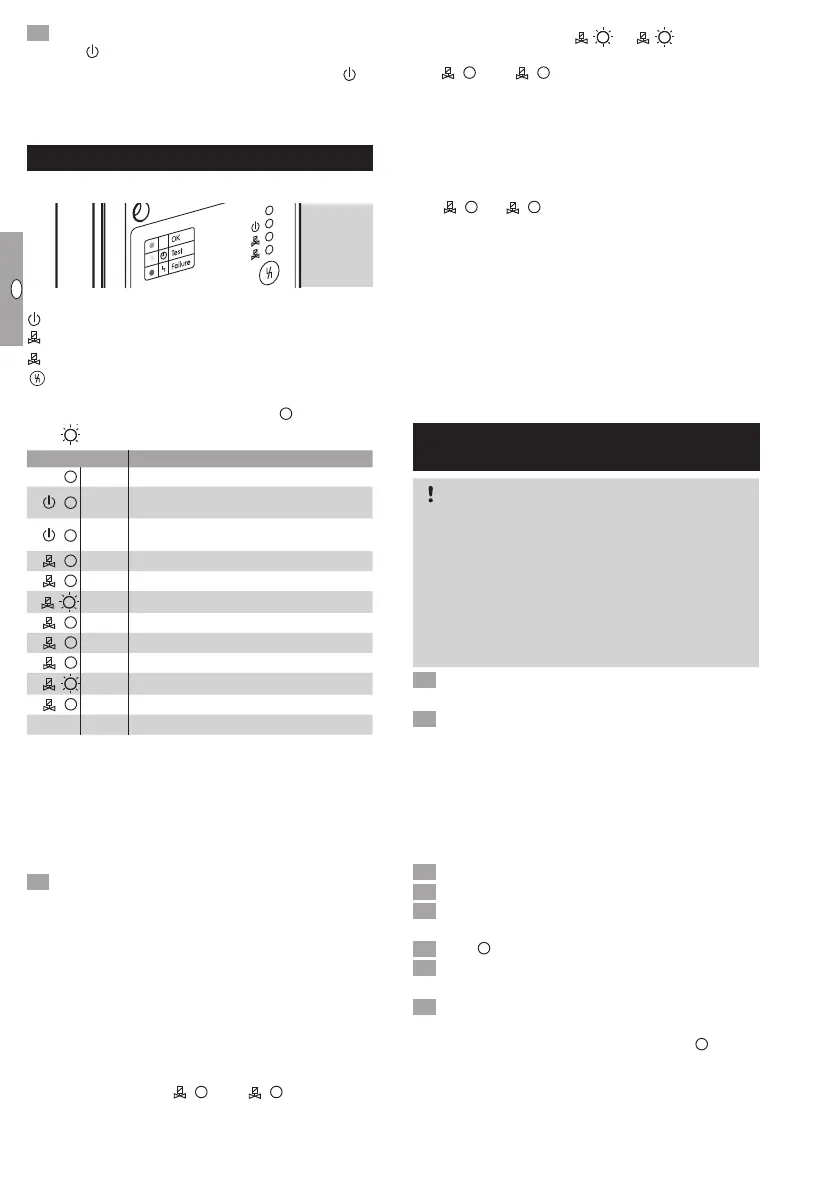

Indicators and operating controls

1

2

Power

= power supply

= operating signal

= valve 1

= valve 2

= reset button

The LEDs can display messages using three colours

(green, yellow, red) and permanent

or flashing

light

:

LED Messages/Operating status

green Power supply OK

yellow

TC is ready for operation; no safety

interlock* input signal

green

TC is ready for operation; active

safety interlock* input signal

green V1 is tight

yellow V1 is untested

1

yellow Tightness test is running on V1

red V1 is leaking

green V2 is tight

yellow V2 is untested

2

yellow Tightness test is running on V2

red V2 is leaking

All yellow Initialization

* Linking of all the relevant safety control and switching

equipment for the use of the application. The burner

start enable signal is issued via the safety interlock

output (terminal 6).

▷

For further messages, see page 8 (Assis-

tance in the event of malfunction).

Switch on the mains voltage.

▷

All LEDs are yellow for 1s. The TC is in the

initialization phase.

▷

The test starts according to the test instant

(Mode) which has been set.

Mode 1 or Mode 3, test before burner start-up:

voltage is applied to terminal 10 (thermostat/

start-up signalϑ).

Or

Mode 2, test after burner run: the TC shows the

last operating status. In the case of untested

valves, the LEDs

and

are yellow.

There is mains voltage at terminal1 and renewed

test after switching off the voltage to terminal10

(thermostat/start-up signalϑ).

▷ During the test, the

1

or

2

LED flashes

yellow.

The

and

LEDs are green:

▷ Both valves are tight.

Mode 1 or Mode 3: the enable signal is issued via

terminal6 when voltage is applied to terminal5.

Or

Mode 2: the enable signal is issued via terminal6

when voltage is applied to terminals 10 and5.

The

or

LED is red:

▷ A valve is leaking.

▷ Voltage at terminal 12. A fault signal is output.

Power failure

▷ If the power fails briefly during the test or during

operation, the tightness test will restart in accord-

ance with the test procedure described above.

▷ If there is a fault message, the fault is displayed

again after a power failure.

Assistance in the event of

malfunction

CAUTION

Electric shocks can be fatal!

– Before working on possible live components,

ensure the unit is disconnected from the power

supply.

– Fault-clearance must only be undertaken by

authorized trained personnel!

– (Remote) resets may only be conducted by au-

thorized trained personnel.

• Faults may be cleared only using the measures

described below.

• Press the reset button to test whether the TC

restarts.

▷

If the tightness control will not start even though

all faults have been remedied, remove the entire

TC (in the case of TC 3, including auxiliary valves

and corresponding valve block) and send it to

the manufacturer for inspection.

? Fault

! Cause

• Remedy

?

red and permanently lit?

! There is over-/undervoltage. The TC performs a

safety shut-down.

• Check the mains voltage. As soon as there is

no longer over-/undervoltage, the TC returns to

normal operating mode and the

LED is

green. It is not necessary to reset the device.

Loading...

Loading...