S9361A207X INTEGRATED BOILER CONTROLLERS

3 69-2751—05

14,000,485-016 1/4 in. (6.35 mm) diameter, 1-1/4 in.

(31.75 mm) length glass cartridge Fuse, 1 A,

Slow-Blow.

120650 Heat Conductive Compound.

Ignition Cables:

32004766-012—36-in. standard ignition cable (one

end with 90° boot, and other end with 1/4-in. quick

connect).

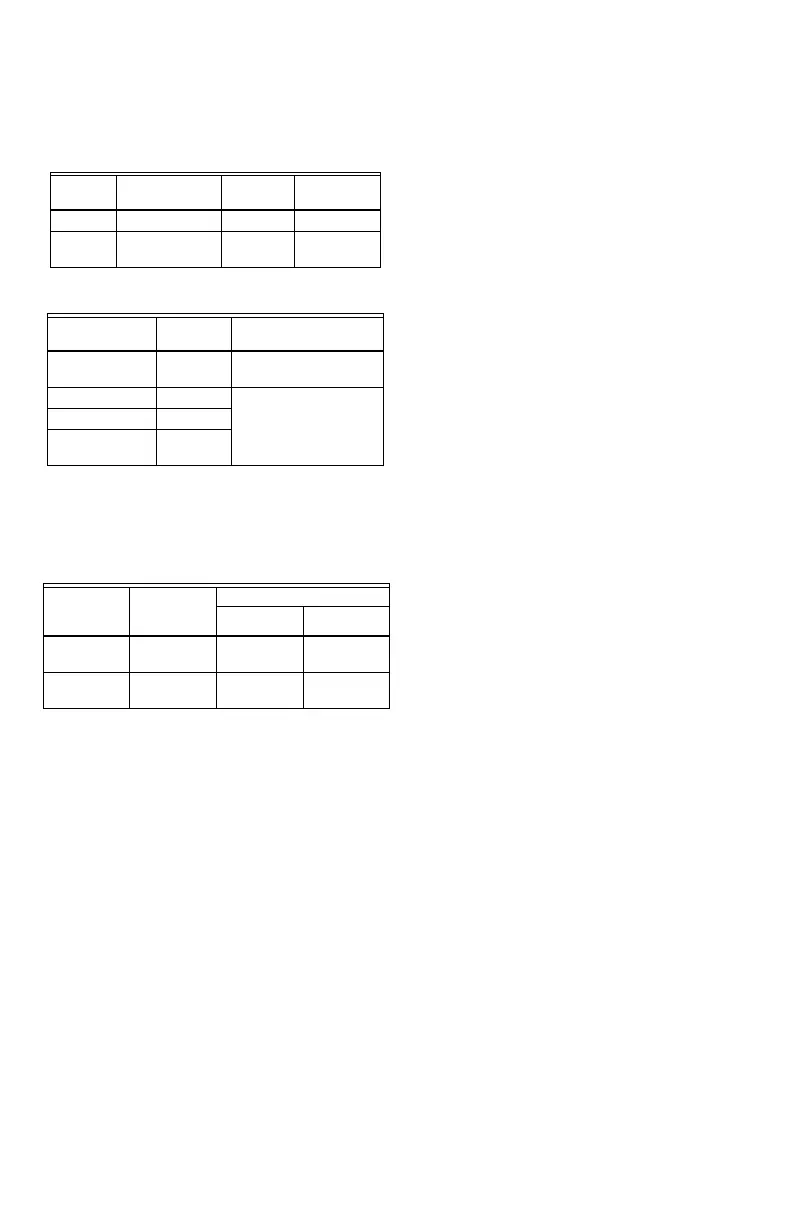

Use cable types recommended in Table 3.

Table 3. Recommended Ignition Cables.

Transformer Requirement:

Add current ratings of module, pilot valve, main valve,

vent damper and any other components of the con-

trol system to determine transformer size require-

ment.

The AT150B1260—commonly used 50 VA transformer.

Approvals:

Varies with control model.

ANSI Z21.20 Automatic Gas Ignition Systems and

Components.

ANSI Z21.23 Gas Appliance Thermostats.

ANSI Z21.87: Automatic Gas Shutoff Devices for Hot

Water Supply Systems.

UL353 Limit Controls.

INSTALLATION

Automatic Ignition Control domestic and commercial

boiler systems are used on a wide variety of

equipment. Some of these applications may make

heavy demands on the controls, either because of

frequent cycling, or because of moisture, corrosive

chemicals, dust or excessive heat in the environment.

In these situations, special steps may be required to

prevent nuisance shutdowns and premature control

failures. These applications require Honeywell

Engineering review; contact your Honeywell Sales

Representative for assistance.

Frequent Cycling

These controls are designed for use on domestic and

commercial boiler systems that typically cycle less

than 10,000 cycles per year. In an application with

significantly greater cycling rates, we recommend

monthly checkout because the controls may wear out

more quickly.

Water or Steam Cleaning

Once a module or gas control has been wet, it may

operate unreliably and must be replaced. If the

appliance is likely to be cleaned with water or steam,

the controls and associated wiring should be covered

so that water or steam cannot reach them. The

controls should be high enough above the bottom of

the cabinet so they will not be subjected to flooding or

splashing during normal cleaning procedures. If

necessary, shield the controls to protect them from

splashing water. A NEMA 4 enclosure is

recommended.

High Humidity or Dripping Water

Over time, dripping water or high ambient humidity

can create unwanted electrical paths on the module

circuit board, causing the module to fail. Never install

an appliance where water can drip on the controls.

In addition, high ambient humidity can cause the

control to corrode and finally fail.

Where the appliance may be installed in a humid

atmosphere, make sure air circulation around the

module and gas control is adequate to prevent

condensation. It is also important to regularly check

out the system. A NEMA 4 enclosure may be needed.

Corrosive Chemicals

Corrosive chemicals can also attack the module and

gas control and eventually cause a failure. Where

chemicals may be used routinely for cleaning, make

sure the cleaning solution cannot reach the controls.

Where chemicals are likely to be suspended in the air,

as in some industrial and agricultural applications,

protect the module from exposure with a NEMA 4

enclosure.

Dust or Grease Accumulation

Heavy accumulation of dust or grease may cause the

controls to malfunction. Where dust or grease may be

a problem, provide covers for the module and gas

control that limit environmental contamination. A

NEMA 4 enclosure is recommended for the module.

Heat

The controls can be damaged by excessively high

temperatures. Make sure the maximum ambient

temperature at the control locations will not exceed

the rating of the control. If the appliance normally

operates at very high temperatures, insulation,

shielding, and air circulation may be necessary to

protect the controls. Proper insulation or shielding

should b provided by the appliance manufacturer;

make sure adequate air circulation is maintained

when the appliance is installed.

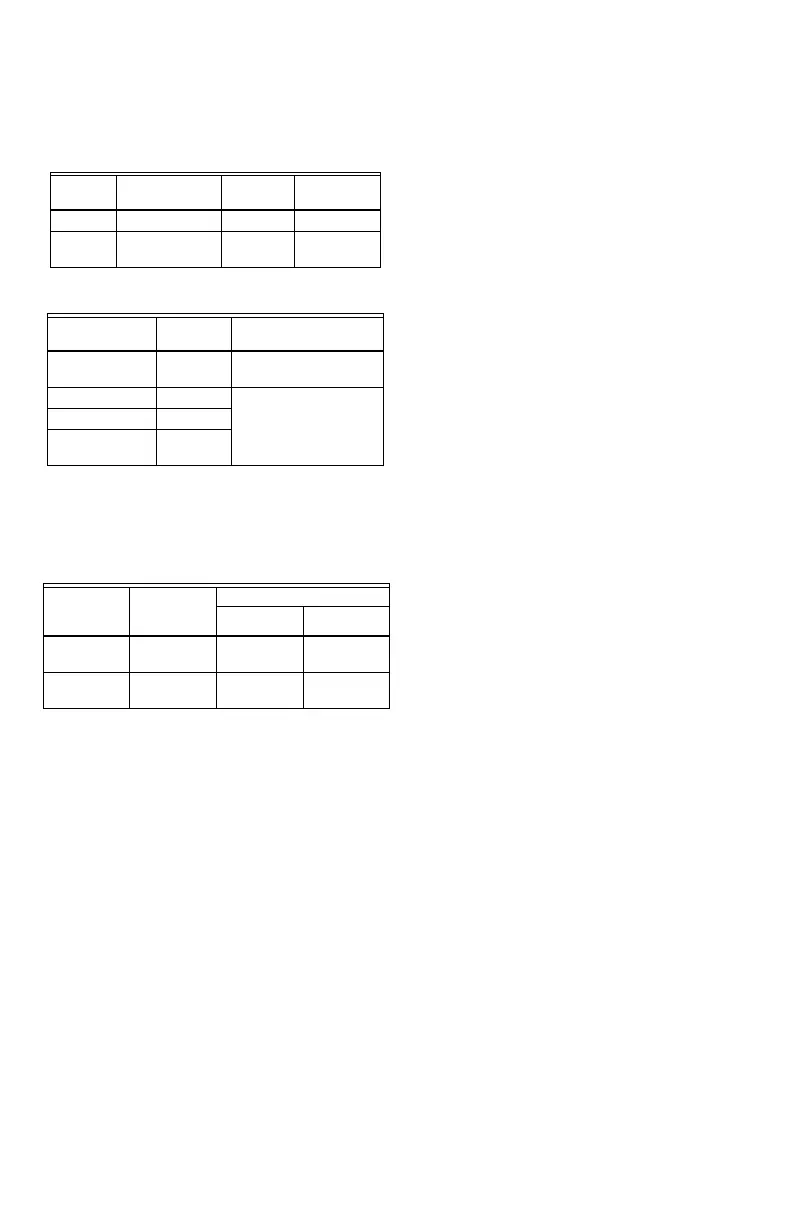

Table 1. Wells for Controller.

Part

Number

Spud Size

in. (mm)

Insertion

in. (mm)

Insulation

in. (mm)

123869A 1/2 (12.7) NPT 3 (76.2) 1-1/2 (38.1)

123870A 3/4 (19.05)

NPT

3 (76.2) 1-1/2 (38.1)

Table 2. Sensors for Controller.

Part Number

Length in.

(mm) Application

50001464-001 12 (304.8) Well-mounted

controls

50001464-003 24 (609.6) Flush-mounted

controls

50001464-004 36 (914.4)

50001464-005 48

(1219.2)

Cable Type

Voltage

Rating

(rms)

Temperature Rating

°C °F

UL Style

3217

10,000 150 302

UL Style

3257

10,000 250 484

Loading...

Loading...