V4730C/V8730C/V4734C · Edition 05.23

EN-11

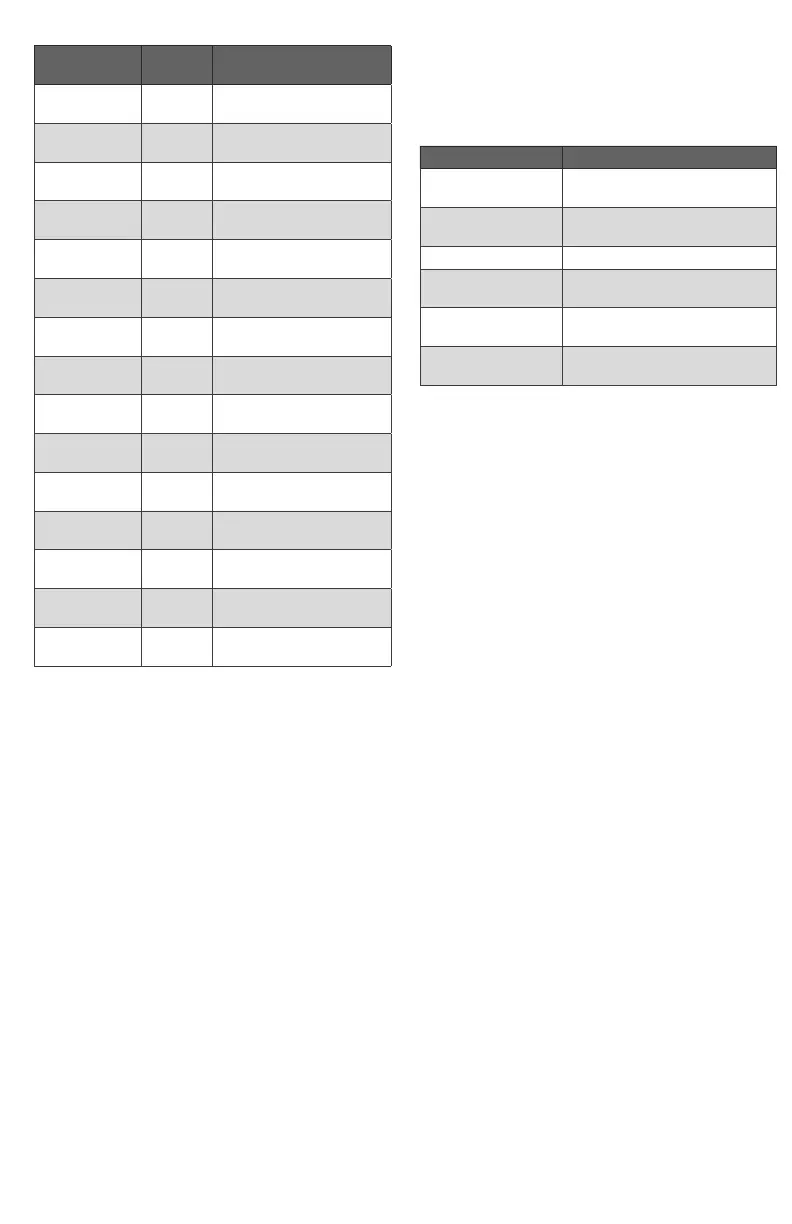

Capacity:

Type VMU

Capacity (natural gas

0.64kg/m

3

)

V4730C1006 150

22–150kW

(73–512 kBtu/hr)

V4730C1014 185

26–185kW

(89–622 kBtu/hr)

V4730C1022 300

43–300kW

(144-1009 kBtu/hr)

V4730C1022 335

48–335kW

(161-1127 kBtu/hr)

V4730C1030 300

43–300kW

(144–1009 kBtu/hr)

V4730C1030 335

48–335kW

(161–1127 kBtu/hr)

V4734C1002 400

55–382kW

(185–1300 kBtu/hr)

V4734C1002 500

71–500kW

(245–1710 kBtu/hr)

V4734C1002 680

97–680kW

(326–2287 kBtu/hr)

V8730C1007 150

22–150kW

(73–512 kBtu/hr)

V8730C1015 185

26–185kW

(89–622 kBtu/hr)

V8730C1023 300

43–300kW

(144–1009 kBtu/hr)

V8730C1023 335

48–335kW

(161–1127 kBtu/hr)

V8730C1031 300

43–300kW

(144–1009 kBtu/hr)

V8730C1031 335

48–335kW

(161–1127 kBtu/hr)

Maximum operating pressure (UL)

1.45psi (100mbar),

except for 1-1/4inch size:

(24V): 1psi (70mbar),

(120V): 1.45psi (100mbar).

CSA Approved to 0.5psi (34mbar).

Torsion and bending stress

Pipe connections meet group 2 according to

EN13611 requirements.

Electrical connections:

Standard plug connector (according DIN43650)

with 36inch (914mm) lead wires.

Valve position indicator lamps:

Inboard (closest to the valve body) - V1.

Outboard - V2.

Ambient temperature range:

5 to +140°F (-15 to +60°C)

Storage temperature = transport temperature:

-20 to +40°C (-4 to +104°F).

Coil insulation solenoid valves:

Class F insulation system.

Body Material:

Aluminum alloy, die-cast.

Strainer:

Fine mesh screen (0.135 in. [0.34mm] diameter).

AISI 303 steel, serviceable after removing inlet flange

screws. Meets EN161 requirements for strainers.

Seals and Gaskets:

Hydrocarbon-resistant NBR and Viton rubber types.

Enclosure: NEMA 1 (IP 40)

11.1 Tightening torque

Recommended tightening torques for the connec-

tion parts:

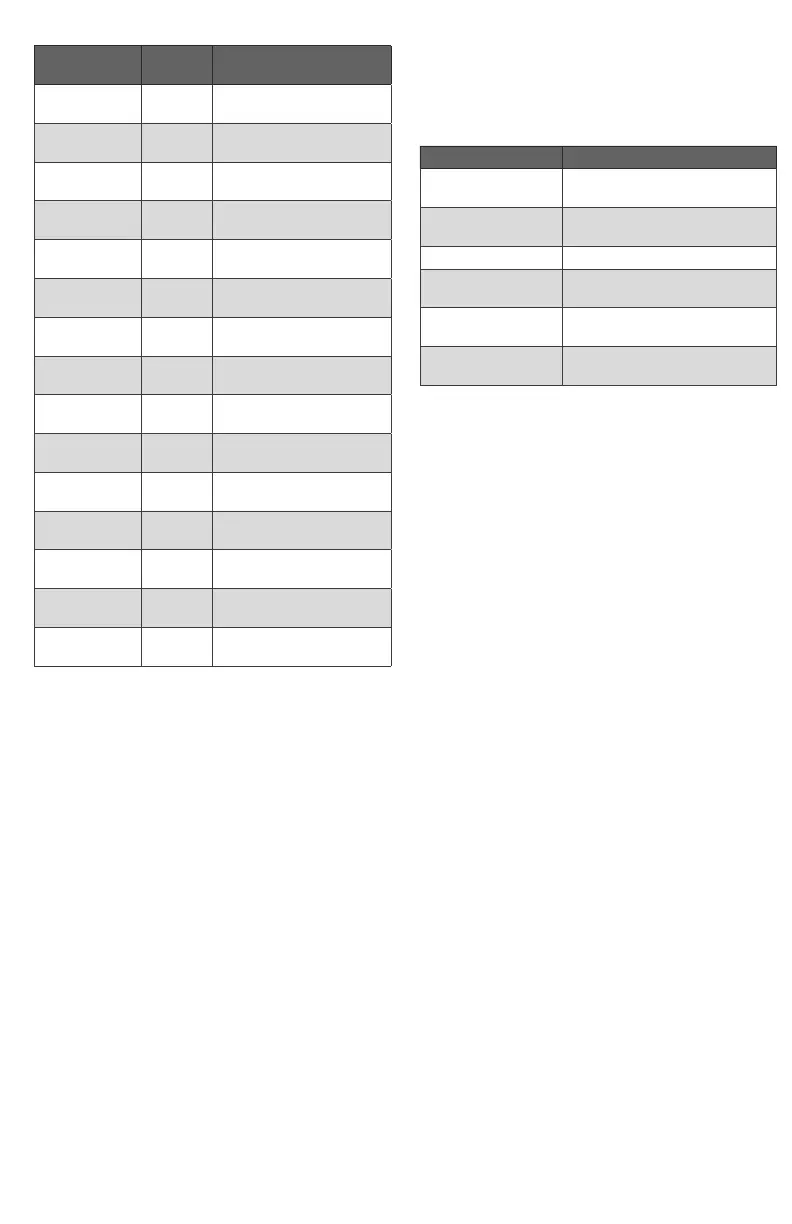

Screw type Tightening torque

Throttle screw

adjustment

max. 4.4 lb-in

min. 0.35 lb-in

Flanges

max. 8.8 lb-in

min. 0.04 lb-in

Pressure tap plug 62 ± 8.8 lb-in

Pressure switch

mounting

22 ± 13 lb-in

Pressure switch

cover

10.6 ± 1.8 lb-in

Inlet/outlet flange

screw

38 ± 3.5 lb-in

11.2 Perfomance characteristics

Opening time:

Dead time maximum 1 second.

First valve opening: <0,5 second.

Second valve opening: reaches 50% of the adjusta-

ble outlet pressure within 5 seconds.

Maximum allowable leakage:

Outerwall, safety valve and main valve = 2.5inch

3

/h

(40 cm

3

/h for upto DN 25 and 3inch

3

/h (50 cm

3

/h)

for DN 32 at test pressure of 0.87psi (6mbar) and

1.5 x maximum operating pressure.

High pressure test:

In the “OFF” condition, the valve will withstand

21.75psi (1.5bar) inlet pressure without damage.

Operational voltage range:

The combination gas valve will function satisfactorily

between 85% and 110% of the rated voltage.

Gas Valve Connection to Venturi (Field-Assembled):

Four screws and an O-ring are used to connect the

gas valve to the venturi/manual shutoff valve.

The metal tube provided with the venturi must be

connected between the venturi and the gas valve

regulator.

Fan Connection:

The venturi is connected to the fan using six bolts

(which are included with VMU).

Minimum Load:

The minimum load for which the system can be

used is 14–17% of the reference load, which equals

a minimum pressure differential of 0.2inch WC

(50Pa) of the 1:1 venturi/servo regulator gas control.

Loading...

Loading...