V4730C/V8730C/V4734C · Edition 05.23

EN-2

2 CHECKING THE USAGE

The 1:1 Gas/Air Servo Regulated Valves, with an

additional venturi mixing unit (VMU) and a fan, are

used for modulating premixing units, such as gas

burners, gas boilers, roof units, fresh air units and

process applications.

This function is only guaranteed when used within

the specified limits – see page 10 (11 Technical

data). Any other use is considered as non-compliant.

See instruction sheet VMU "VMU Series Venturi

Mixing Unit for V473xC/V873xC Combination Gas

Controls" www.docuthek.com.

Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

2.1 Type code

V Safety shut-off valve

4 Line voltage

73 Combination control

0 Small body size models

4 Large body size models

C Integrated gas/air 1:1

xxxx Specification number

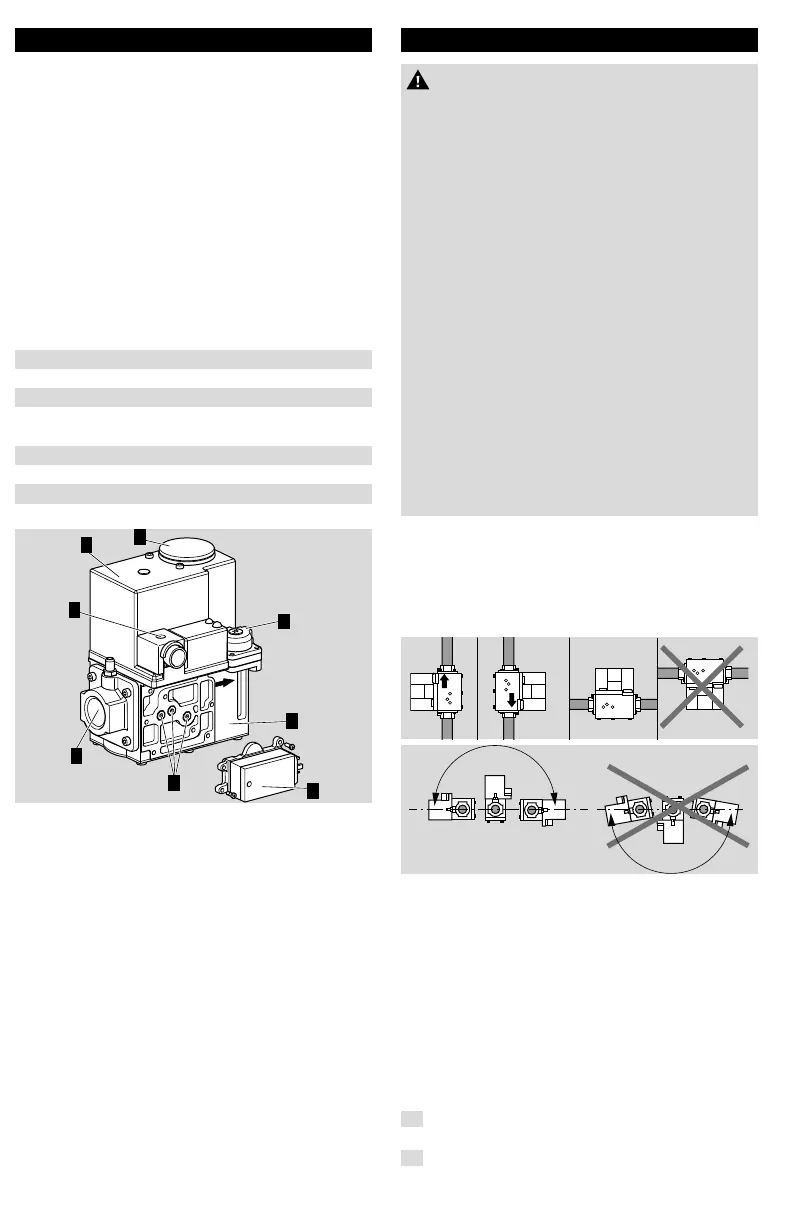

2.2 Part designations

4

6

1

5

2

8

7

1 Main body

2 Cover

3 Cap

4 Servo regulator gas/air 1:1

5 Pressure tap points

6 Inlet flange

7 Electrical connection

(connector type: ISO 4400/DIN43650 Form A)

8 Pressure switches (Option)

3 INSTALLATION

CAUTION

Incorrect installation

Please observe the following to ensure that the

unit is not damaged during installation and oper-

ation:

– Sealing material and dirt, e.g. thread cuttings,

must not be allowed to get into the valve

housing.

– Dropping the device can cause permanent

damage. In this event, replace the entire device

and associated modules before use.

– Turn off gas supply before installation.

– Disconnect power supply to the valve actuator

before beginning the installation to prevent

electrical shock and damage to the equipment.

– Do not remove the seal over valve inlet and

outlet, until ready to connect piping.

– The valve must be installed so that the arrow on

the valve points in the direction of the gas flow

(gas pressure helps to close the valve).

– Screws which are protected against unauthor-

ised removal must not be loosened. This will

invalidate the warranty!

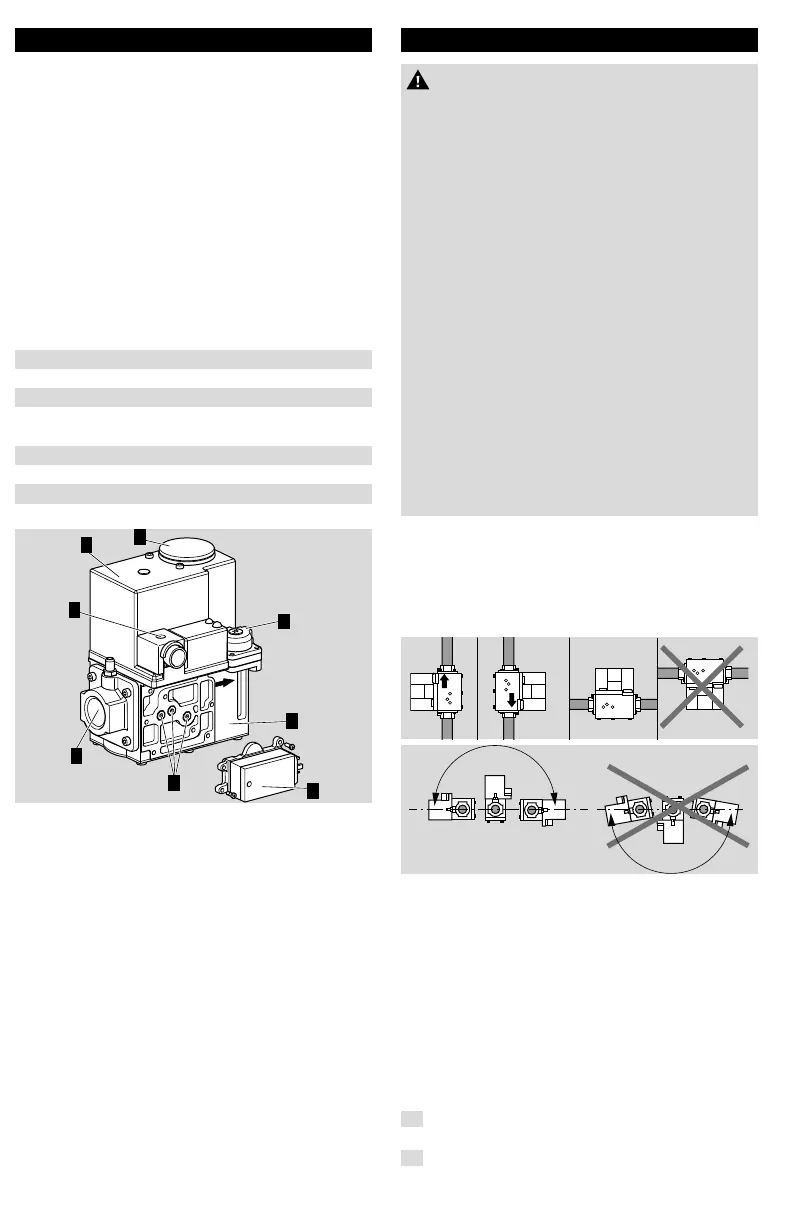

3.1 Installation position

Solenoid actuator in the vertical upright position or

tilted up to the horizontal, not upside down.

Gas valves with integrated gas/air 1:1: The factory

settings are made in a horizontal installation position.

A vertical installation may require readjustments.

The distance between the gas valve and the wall/

ground, must be at least 30 cm.

➔ The valve can be mounted up to ±90 degrees

from this position without affecting the fuel/air

metering at medium and high firing rates (3000

to 5000 rpm of the blower), but at lower firing

rates (1000 rpm) the fuel might be reduced up

to 10% when the valve is not mounted horizontal.

To counter this, the low fire gas flow may be

carefully field adjusted for non-horizontal mount-

ing as described below.

3.2 Install valve

1

Take care that dirt does not enter the gas valve

during handling.

2

Remove flanges from the valve (if factory

mounted).

Loading...

Loading...