21

8 Transport and installation

The following checks must be performed before installation:

■ Has the rotary heat exchanger been damaged during

transport (visual inspection of casing and wheel)?

■ Has the correct model been supplied (type, series, size,

options)?

■ How must the exchanger be mounted (purge sector)?

(Note labels!)

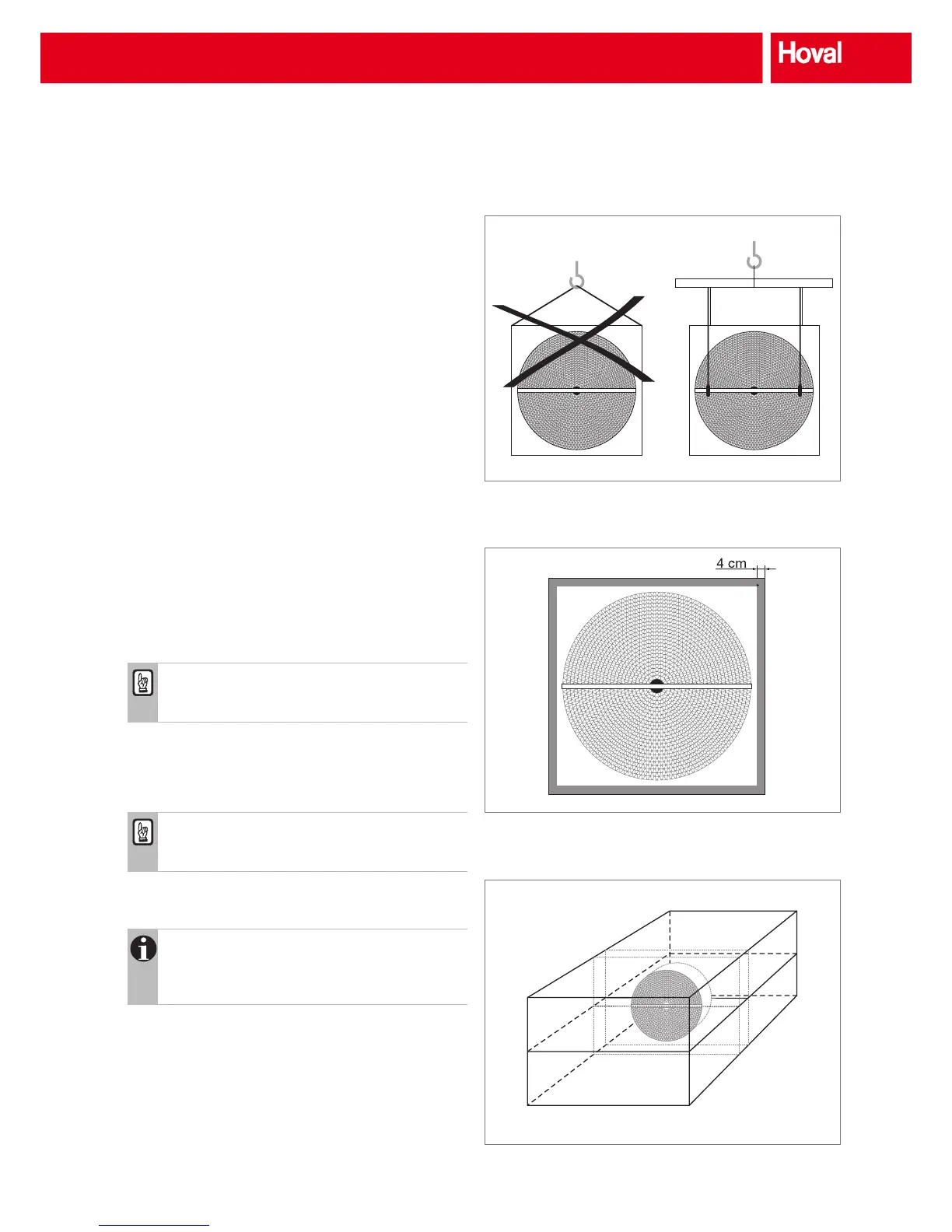

8.1 Transport

■ The wheel should always be vertical during transport.

■ The rotary heat exchanger should be attached to the

crossbars of the casing. The pulling direction should be

vertical to prevent damage.

■ The following general items are applicable: Do not lift the

exchanger at a single point but always suspend it by a

crane beam (Fig. 20).

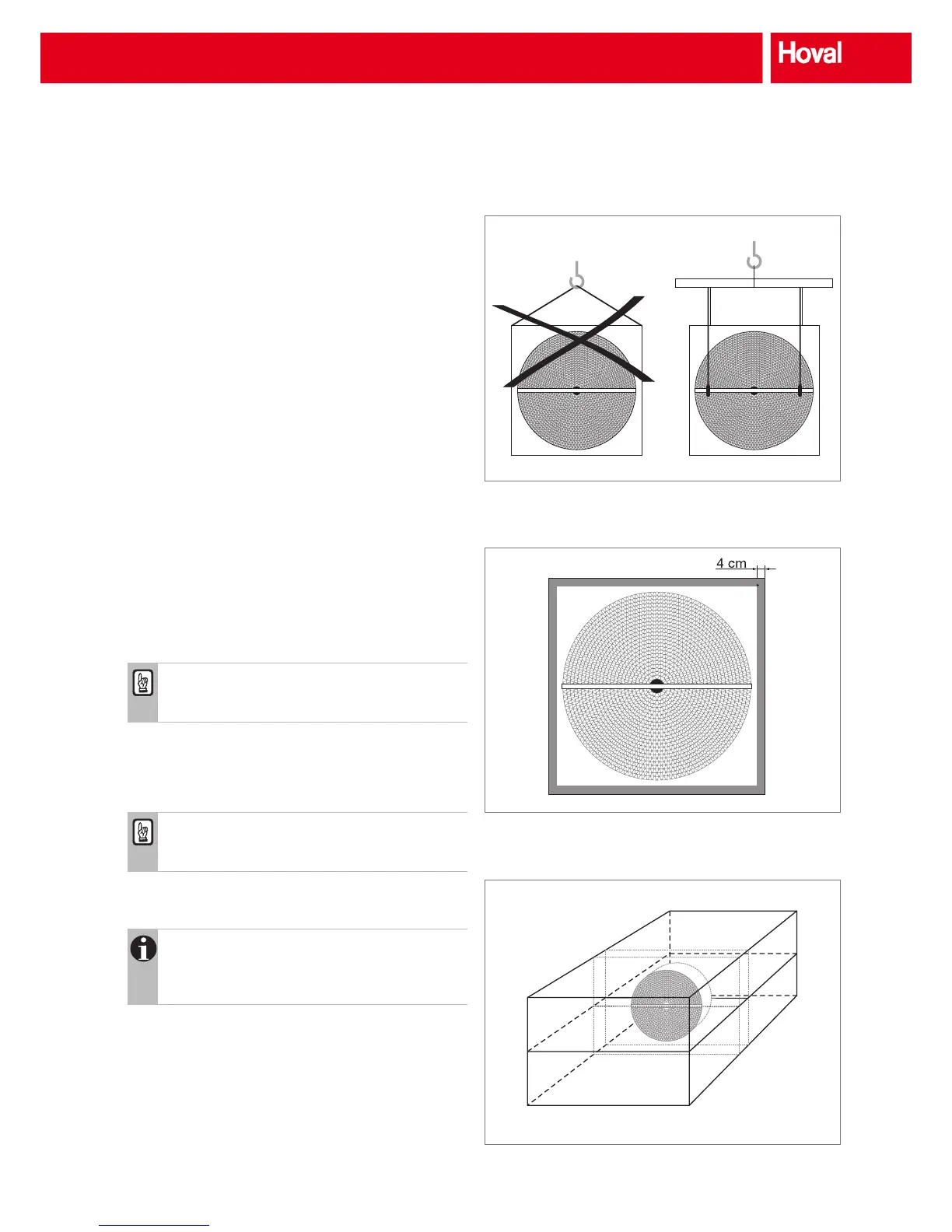

8.2 Mechanical installation

■ The casing for duct connection can be bolted or riveted at

the face area up to 4 cm from the outer frame (Fig. 21).

Caution

The wheel casing cannot take any additional load

(e.g. ducts).

■ When installing the wheel in a ventilation unit, the casing

should be reasonably adapted to the unit size (Fig. 22).

■ If necessary, bafe plates can be installed to adapt the

casing to the unit cross-section.

Caution

Ensure that the wheel is not drilled or blocked and

the sealings are not damaged during installation.

■ Hoval rotary heat exchangers are designed for vertical

installation (max. tilt 20°).

Notice

Rotary heat exchangers for horizontal installation

are available on request. In this case the casing

must be supported at the bearings.

■ After installation check that the wheel runs smoothly.

8.3 Installation of sensors

If, for example, temperature sensors are installed, the func-

tion of the unit must not be affected.

Fig. 20: Recommended attachment

Fig. 21: Drill area

Fig. 22: Casing dimensions adjusted for unit

Transport and installation

Loading...

Loading...