6

1.4 Frost limit

If the warm extract air stream is very strongly cooled conden-

sate can be formed and it may even freeze. The fresh air

temperature at which this starts is referred to as the frost

limit.

■ Condensation wheel, enthalpy wheel: The condensate

generated by cooling the extract air may freeze at low

outside temperatures. There is a frost hazard at equiva-

lent mass ows for exhaust air and fresh air if the average

inlet temperature of the two air streams is less than 5 °C.

t

m

=

t

11

+ t

21

2

< 5 °C

■ Sorption wheel: The gaseous humidity transmission by

sorption generally prevents condensation; the frost hazard

is reduced.

1.5 Temperature efficiency

Appropriate design and serial layout allows virtually any

temperature efciency to be reached. The 'correct' temper-

ature efciency depends on the applicable regulations and

the economy calculations, i.e. the operating data such as

energy price, service life, operation time, temperatures,

maintenance requirements, interest etc. Even minor changes

(a few percent lower temperature efciency, a few pascals

more pressure drop) can mean signicantly poorer results for

capital value and amortisation period.

1.6 Pressure drop

Heat recovery units cause pressure drop on the extract

and supply air sides and as a result operating costs. With

current general conditions the economical values for wheels

are between 80 Pa and 130 Pa. However, to reduce costs,

more and more heat recovery units whose pressure drops

are above these economically reasonable values are being

installed. This affects the feasibility of the system.

1.7 Pressure difference

A distinction is made between internal pressure difference

(between exhaust air and supply air) and external pressure

difference (between the exchanger and the environment).

Internal pressure difference:

The internal leakage between the two air streams depends

greatly on the pressure difference. Hoval rotary heat

exchangers with high tightness seal compared with other

designs are certainly very leak-proof, but the following infor-

mation should be taken into account in the design:

■ The pressure difference in the rotary heat exchanger

should be as low as possible.

■ In applications that involve the danger of odours the pres-

sure gradients and therefore possible leakage from the

fresh air to the exhaust air must be considered.

However, the internal pressure difference may also cause

deformation of the casing; a pressure difference of more than

2000 Pa is not permitted.

Notice

The pressure difference depends on the layout of the

fans. Overpressure on one side and underpressure

on the other side add up.

External pressure difference:

This is a major factor for the external leakage of the heat

exchanger. If a duct system is correctly and carefully

installed, this effect can be ignored.

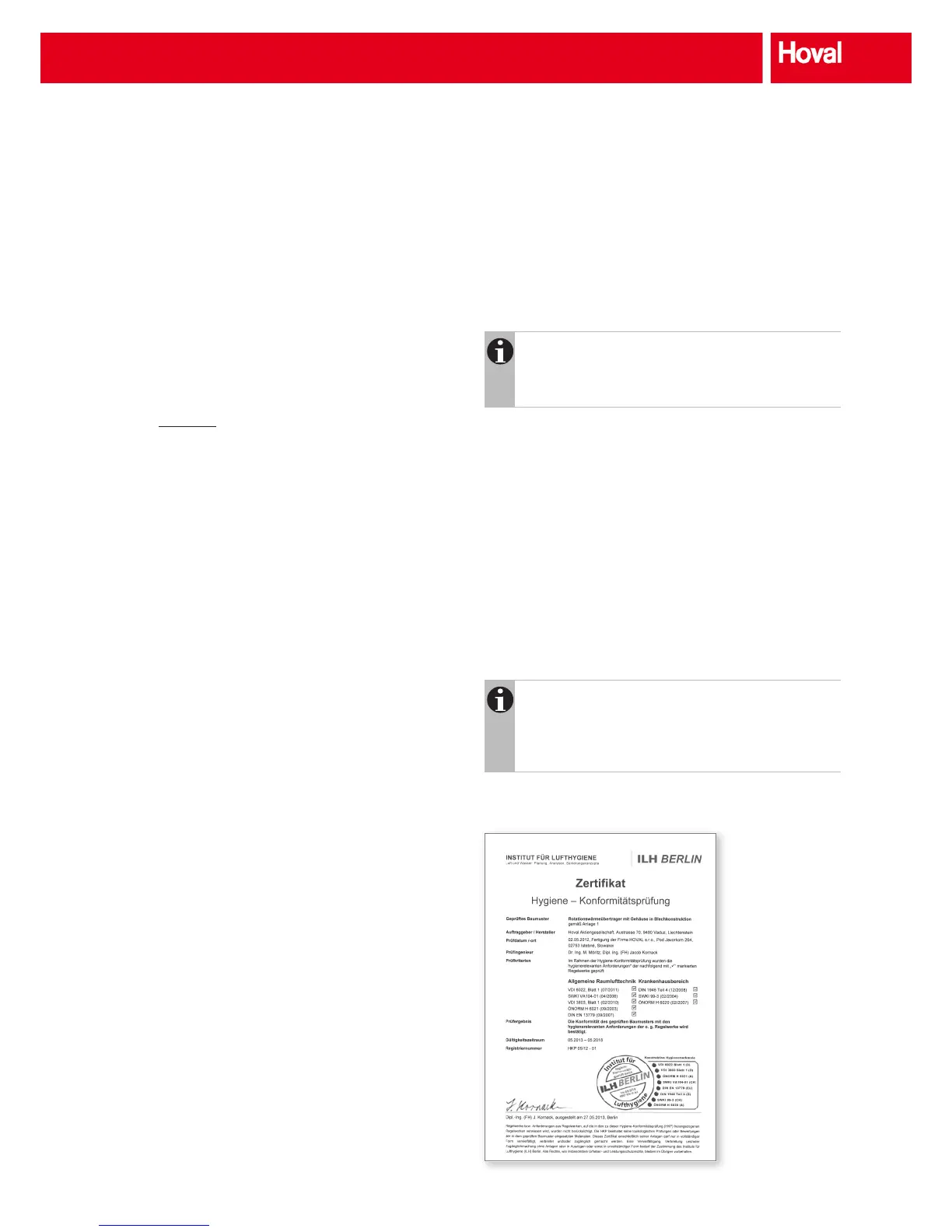

1.8 Hygiene

Hoval rotary heat exchangers with high tightness seal have

been tested for conformity with hygiene requirements at the

Institute for Air Hygiene in Berlin. The test criteria were the

requirements relevant to hygiene for applications in general

building ventilation and in hospital applications. All hygiene

requirements were met.

Notice

Hoval rotary heat exchangers are tested and certi-

ed for operation in hospitals in accordance with

DIN 1946-4. Install rotary heat exchangers with the

'coated casing' option for such applications.

Fig. 6: Certicate of

hygiene conformity test

(valid for Hoval rotary

heat exchangers with high

tightness seal)

Principle and Operation

Loading...

Loading...