2

1 Principle and Operation

Hoval rotary heat exchangers are regenerators with rotating

heat accumulators (category 3) in accordance with the guide-

lines for heat recovery (e.g. VDI 2071).

The heat-dissipating and heat-absorbing air ows heat

or cool the rotating, air-permeable storage accumulator.

Depending on the air conditions and the surface of the

accumulator material, humidity may also be transferred in the

process. Supply and exhaust air must therefore be brought

together and ow through the heat exchanger.

The storage mass consists of triangular, axially arranged

small ducts made of thin metal foil. The depth of the storage

mass (viewed in the direction air ow) is generally 200 mm;

the airway height is normally 1.4 – 1.9 mm, depending on the

application. With these dimensions the storage mass gener-

ates a laminar ow in the wheel ducts.

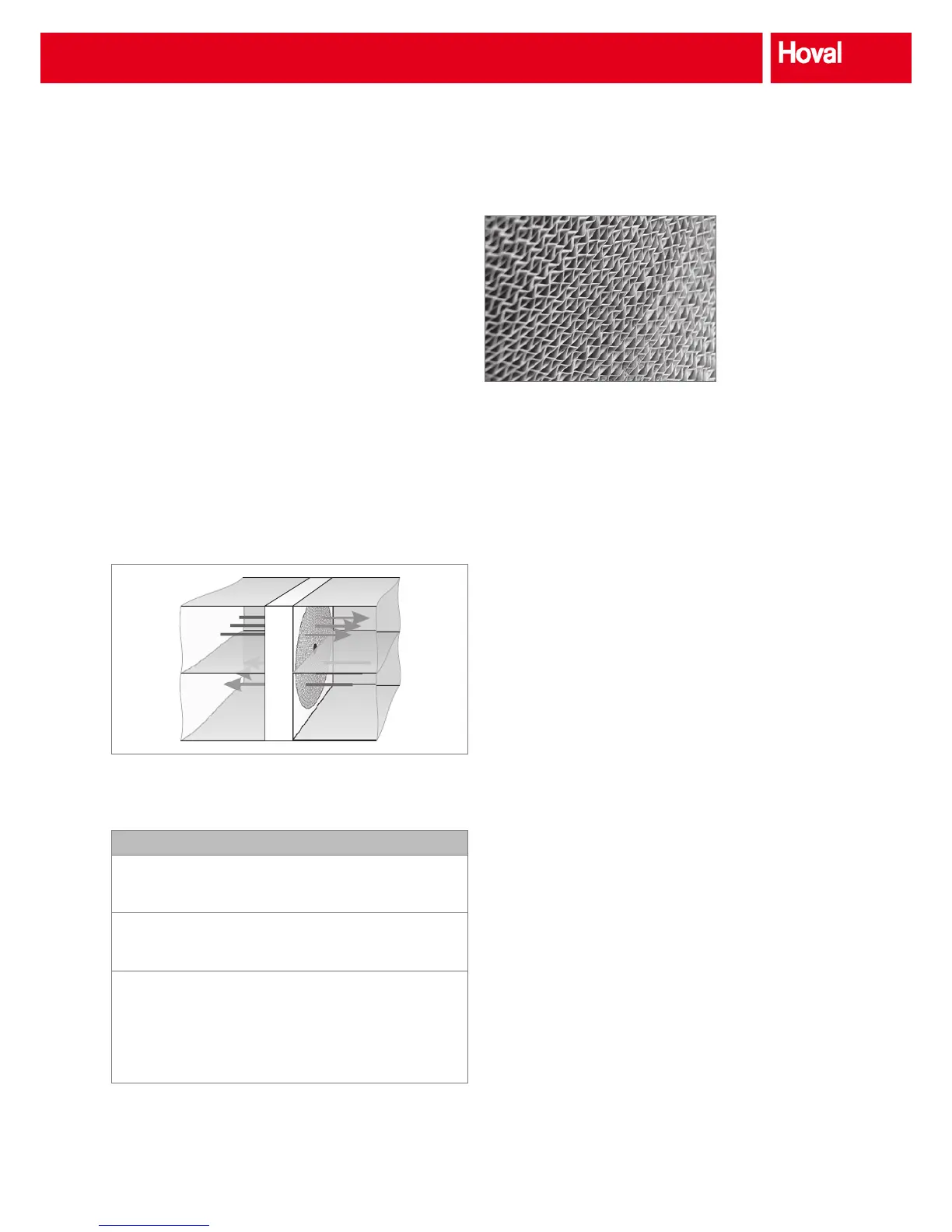

Fresh air

t

21

x

21

Supply air

t

22

x

22

Exhaust air

t

12

x

12

Extract air

t

11

x

11

Fig. 1: Function diagram and air conditions

Denition of key data according to Eurovent

Temperature efciency

t

22

- t

21

η

t

=

t

11

- t

21

Humidity efciency

x

22

- x

21

η

x

=

x

11

- x

21

Legend: t = Temperature [K; °C]

x = Absolute humidity [g/kg]

Index: …

11

Extract air

…

21

Fresh air

…

12

Exhaust air

…

22

Supply air

1.1 Heat transmission

The wheel with its axially arranged, smooth ducts acts as a

storage mass, half of which is heated by the warm air and

the other half of which is cooled by the counter-ow of cold

air. The temperature of the storage mass therefore depends

on the axis coordinates (wheel depth) and the angle of

rotation.

The function is easy to understand by following the status

of a wheel duct through one revolution (see Fig. 3). The

following can be recognised with reference to the heat

transfer from this process:

■ The air temperature after the exchanger varies; it depends

on the location on the wheel.

■ The heat recovery efciency can be varied by varying the

speed.

■ The heat recovery efciency can be changed with the

storage mass. This can be done with different cross-sec-

tions of the wheel ducts, different thickness of the storage

material or by changing the wheel depth. However, in all

cases this varies the pressure drop.

■ The specic heat output depends on the temperature

difference between warm air and cold air. The rotary heat

exchanger is therefore suitable for heat and cool recovery,

i.e. for winter and summer operation.

Fig. 2: Geometry of

storage mass

Loading...

Loading...