1.1 Heat transmission

The wheel with its axially arranged, smooth ducts acts as a

storage mass, half of which is heated by the warm air and

the other half of which is cooled by the counter-ow of cold

air. The temperature of the storage mass therefore depends

on the axis coordinates (wheel depth) and the angle of

rotation.

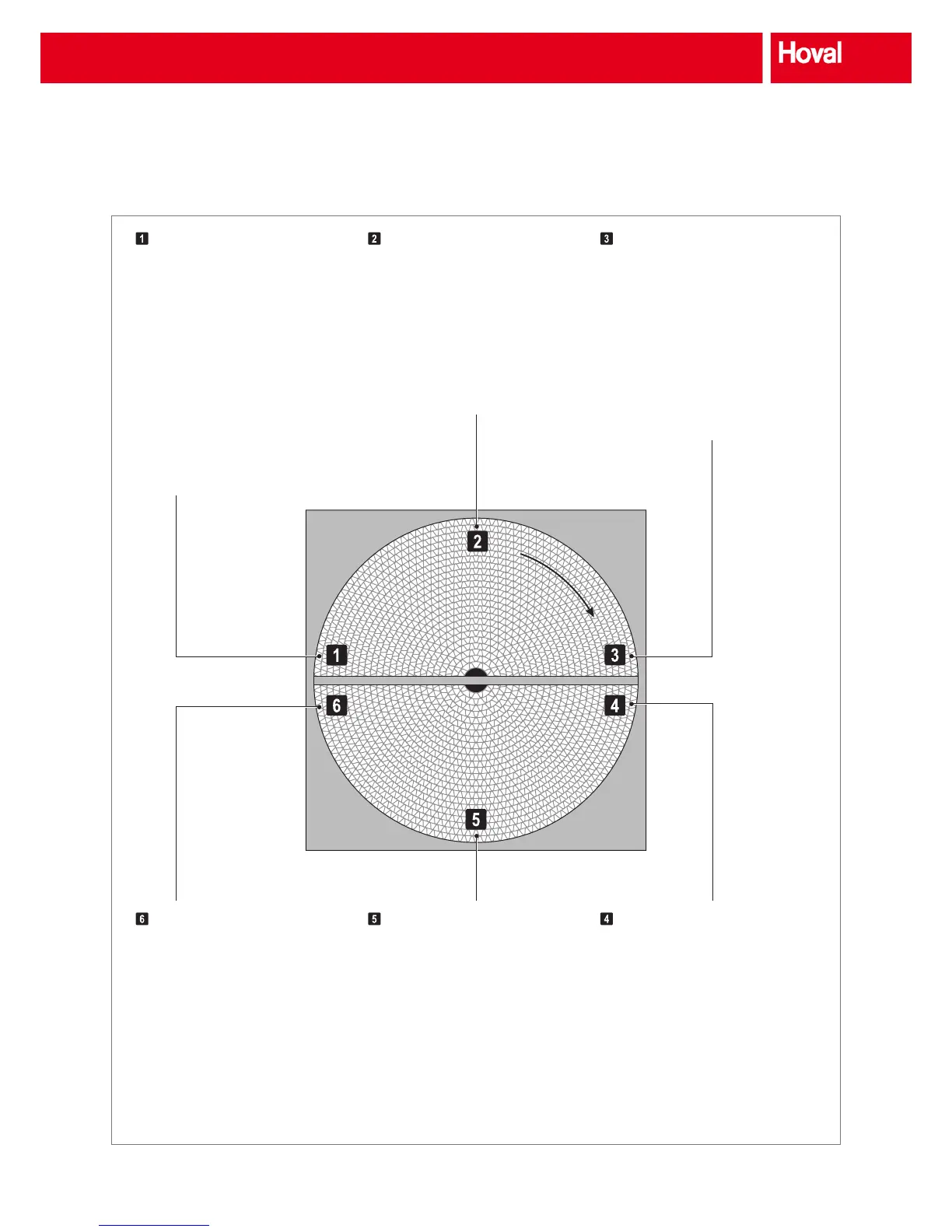

The function is easy to understand by following the status

of a wheel duct through one revolution (see Fig. 3). The

following can be recognised with reference to the heat

transfer from this process:

■ The air temperature after the exchanger varies; it depends

on the location on the wheel.

■ The heat recovery efciency can be varied by varying the

speed.

■ The heat recovery efciency can be changed with the

storage mass. This can be done with different cross-sec-

tions of the wheel ducts, different thickness of the storage

material or by changing the wheel depth. However, in all

cases this varies the pressure drop.

■ The specic heat output depends on the temperature

difference between warm air and cold air. The rotary heat

exchanger is therefore suitable for heat and cool recovery,

i.e. for winter and summer operation.

Fig. 2: Geometry of

storage mass

Fig. 3: States depending on the turning angle

Warm air entry

The rotation of the storage mass has

moved the wheel duct from the cold air

to the warm air. The storage material is

cooled almost to the temperature of the

cold air. This applies particularly to the

entry side of the cold air (= exit side of the

warm air). The warm air now ows through

the duct with reference to the temperature

in the counter-ow and is cooled greatly.

The storage mass is therefore heated. The

local temperature efciency, i.e. directly

at the inlet to the warm air, is very high.

Condensation can also occur very easily.

Mid warm air

The wheel duct now has passed half of

its time in the warm air. The storage mass

has been heated by the owing warm air;

therefore, the warm air is not cooled down

as much as in entry inlet zone. The wall

temperature at the entry and exit is approxi-

mately the same. Condensation occurs only

with large humidity differences.

Warm air exit

The wheel duct is now shortly before entry

to the cold air. It has virtually reached the

temperature of the extract air at the entry

side. The transferred performance is still

only low.

The dwell time in the warm air and in the

cold air, i.e. the speed of rotation, is deci-

sive for the performance of the rotary heat

exchanger. It depends on the storage mass

(thickness, geometry), the heat transfer and

the air velocity.

Cold air exit

The wheel duct has passed through the

cold-air section. The storage mass has

greatly cooled, almost down to the cold-air

temperature in the entry section. After

crossover to the warm air side, the cycle

starts anew.

Mid cold air

Half of the dwell time in the cold air is past.

The storage mass has already cooled

signicantly. The temperatures at the entry

and exit are approximately equal.

Cold air entry

After the transition from the warm air to the

cold air, the wheel duct now has cold air

owing through in the opposite direction

(referring to the temperature). With the

high temperature difference the transferred

performance is very high, i.e. the cold air is

very strongly heated; in reverse the storage

mass is strongly cooled. Any conden-

sate formed on the exchanger surface is

(partially) absorbed by the heated cold air.

W

A

R

M

A

I

R

C

O

L

D

A

I

R

Principle and Operation

Loading...

Loading...