294 214 283 / 00

INSTALLATION

4.8 Minimum value limiting of boiler return

temperature

Hydraulic and technical control measures are to be imple-

mented to ensure that the minimum boiler feed and return

temperatures are not fallen below.

4.9 Setting the temperature controller

Boiler temperature controller, selectable TR 65-85°C

The basic setting is made by the heating installer. Selec-

tion and setting of the different heating programs accor-

ding to operating instructions.

4.10 Boiler safety valve

Heating installations and hot water supply systems are to

be protected against inadmissible overpressure by safety

valves. The blow-off pressure of the heating system safe-

ty valve must correspond to the maximum rated thermal

it's downstream isolating valve.

4.11 Filling pump

(boiler with separate calorifier)

Speed and output regulation must correspond to the re-

made by the heating specialist.

4.12 Heating pump

Speed and output regulation must correspond to the re-

made by the heating specialist.

4.13 Heating connections

In the case of boiler installation in the domestic domain,

-

xible compensators.

4.14 Installing a flue gas thermometer (optional

item)

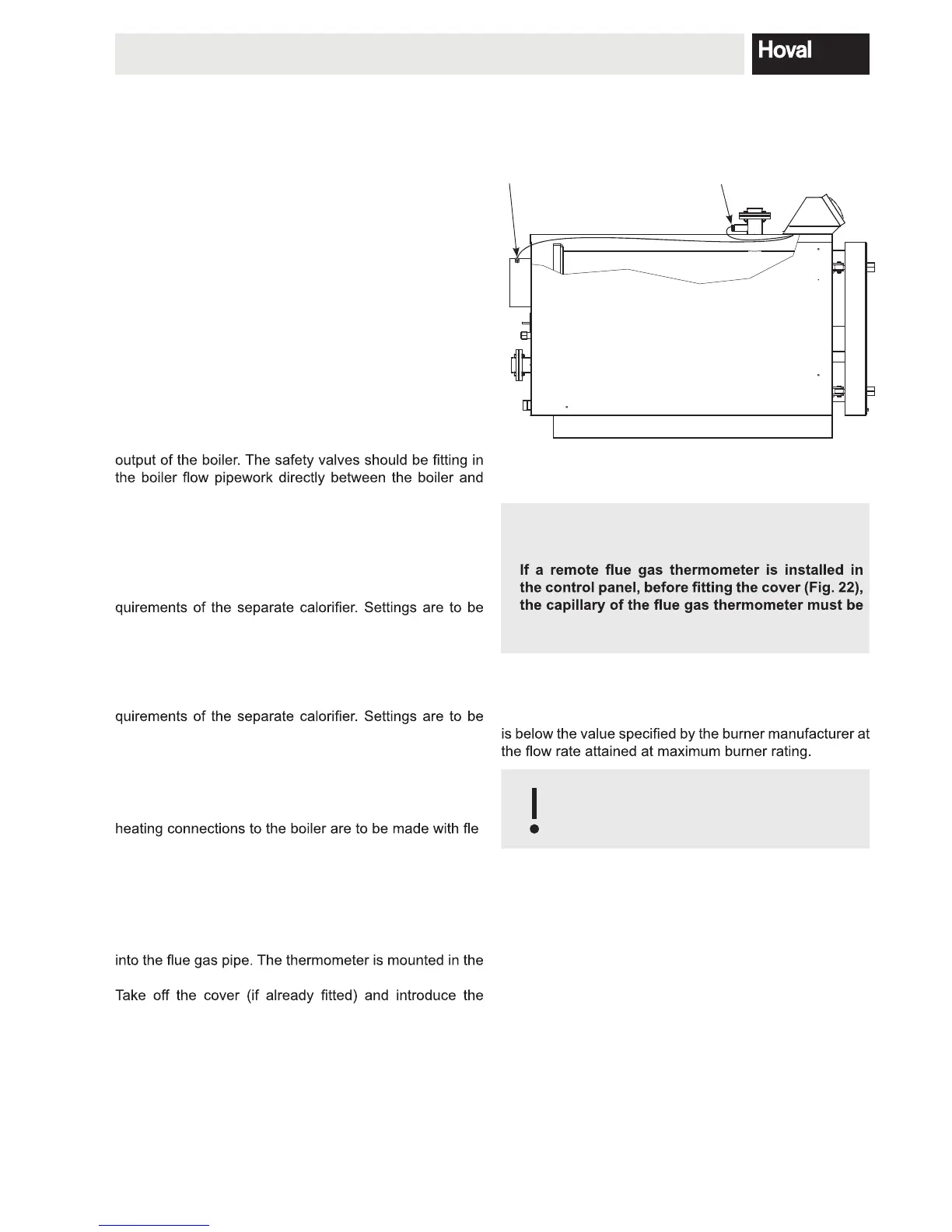

A 3/8” sleeve with a max. length of 25 mm is to be welded

control panel; see Fig. 22.

capillary through the rear wall between the external and

round insulation.

Screw the sensor tube into the sleeve.

STB

Flue gas

temperature sensor

Fig. 22

The capillary must not be kinked.

Important note:

routed on the top, along the boiler insulating mat,

towards the back.

4.15 Gas Boosters

A booster is required when the gas pressure at the burner

Important

If a critical system is served it is good pra-

ctise to install a duty/standby gas booster

Gas Regulations require that no more than 0.5" WG pres-

sure is lost due to pipe work resistance between the sup-

ply meter and the gas inlet.

4.15.1 Booster Installation

It is usually preferably to locate the boosters as near as

possible to the burner served rather than close to the me-

ter.

• Leave adequate access for servicing drive belts, fan

bearing assemblies, electrical motors and any acoustic

shroud.

• Ensure that the room in which the gas booster is to be

installed is well ventilated and free from dust.

set.

Loading...

Loading...