314 214 283 / 00

COMMISSIONING

Heating Water

The European Standard EN 14868 and the

directive VDI 2035 must be observed.

In particular, attention must be paid to the following stipu-

lations:

•

cording to EN 14868).

• Plants with

- continuous oxygen intake (e.g. underfloor heating

systems without diffusion proof plastic piping) or

- intermittent oxygen intake (e.g. where frequent refill-

ing is necessary)

must be equipped with separate circuits.

•

least 1x yearly. According to the inhibitor manufacturer‘s

instructions, more frequent testing may be necessary.

•

water in existing installations (e.g. exchange of boiler)

conforms to VDI 2035.

The Directive VDI 2035 applies equally to the replace-

ment water.

• New and if applicable existing installations need to be

•

water are made of ferrous materials and stainless steel.

• On account of the danger of stress cracking corrosion

in the stainless steel section of the boiler the chloride,

nitrate and sulphate content of the heating water must

not exceed 50 mg/l.

• The pH value of the heating water should lie between

8.3 and 9.5 after 6-12 weeks of heating operation.

Filling and replacement water

• For a plant using Hoval boilers untreated drinking water

ing and replacement water. However, as not all drinking

VDI 2035. Should the mains water available not be

suited for use then it must be desalinated and/ or be

treated with inhibitors. The stipulations of EN 14868

must be observed.

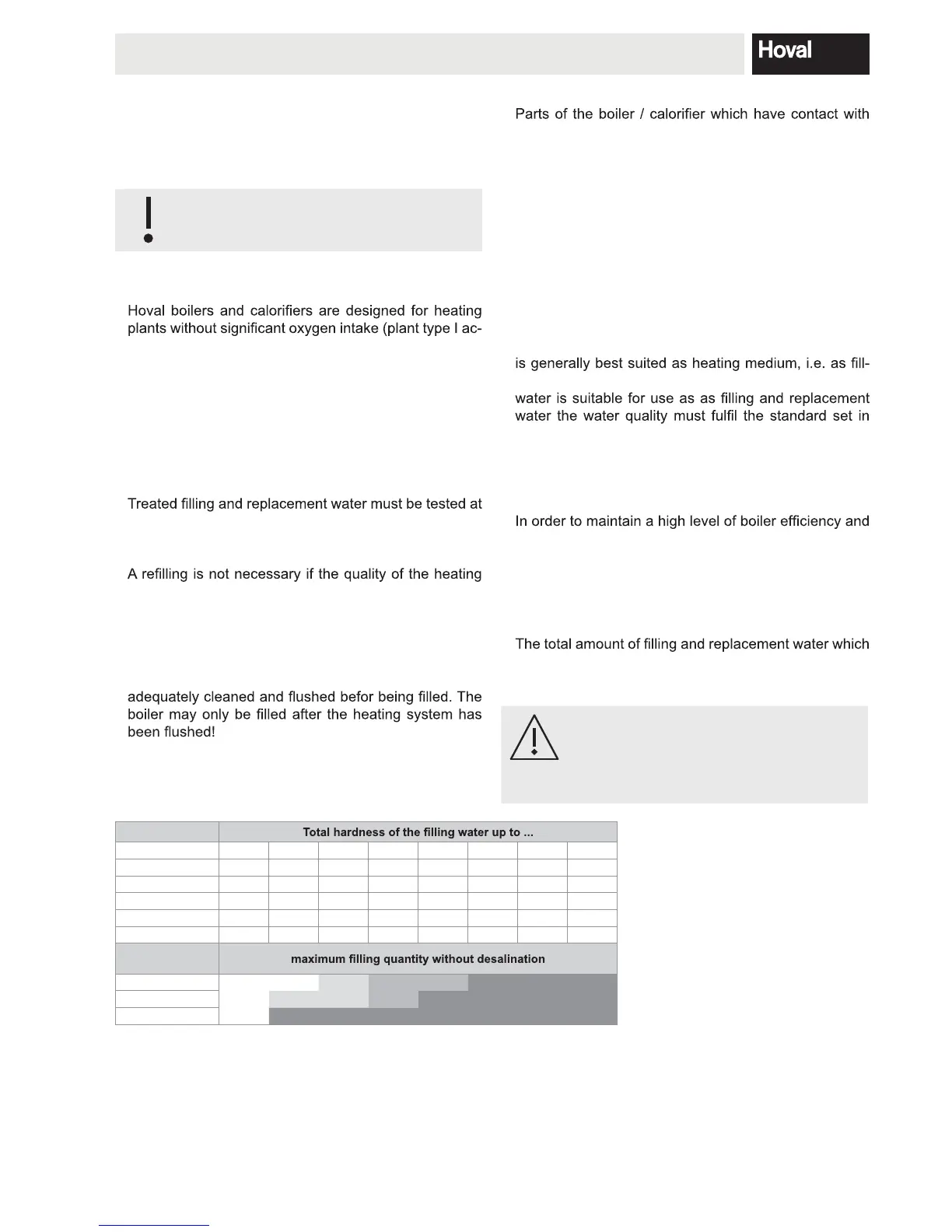

•

to avoid overheating of the heating surfaces the values

given in the table should not be exceeded (dependent

on boiler performance ratings - for multi-boiler plants

rating of smallest boiler applies - and on the water con-

tent of the plant).

•

is used throughout the total service life of the boiler

must not exceed three times the water capacity of the

plant.

Maximum filling capacity based on VDI 2035

[mol/m

3

]

1

<0,1 0,5 1 1,5 2 2,5 3 >3,0

f°H <1 5 10 15 20 25 30 >30

d°H <0,56 2,8 5,6 8,4 11,2 14,0 16,8 >16,8

e°H <0,71 3,6 7,1 10,7 14,2 17,8 21,3 >21,3

~mg/l <10 50,0 100,0 150,0 200,0 250,0 300,0 >300

Conductance

2

<20 100,0 200,0 300,0 400,0 500,0 600,0 >600

Boiler size of the

individual boiler

50 to 200 kW NO REQUI- 50 l/kW 20 l/kW 20 l/kW

always desalinate200 to 600 kW RE- 50 l/kW 50 l/kW 20 l/kW

over 600 kW MENT

1

Sum of alkaline earths

2

If the conductance in μS/cm exceeds the tabular value an analysis of the water is necessary.

5. Commissioning

5.1 Water quality

NOTE:

No continous make-up of water should be

taking place during boiler operation. In

this event check where a leak may be oc-

curing or if pumping over is taking place.

Loading...

Loading...