Strain Gage Measurements

Although the instrument does not directly support strain measurements,

you can measure a strain gage using a 4-wire resistance measurement

with scaling. However, HP BenchLink Data Logger software has built-in

strain gage measurement capability.

When a force is applied to a body, the body deforms. The deformation

per unit length is called strain (

ε). Strain may be either tensile (+) or

compressive (-). Practical strain values are usually quite small

(typically less than 0.005 inch/inch for most metals) and are often

expressed in micro-strains (

µε). There are three common types of strain

measurements as shown below.

Stress Stress is a term used to compare the loading applied to a

material with its ability to carry the load. Stress (

σ) in a material can

not be measured directly; it must be computed from material properties

and measurable quantities such as strain and force.

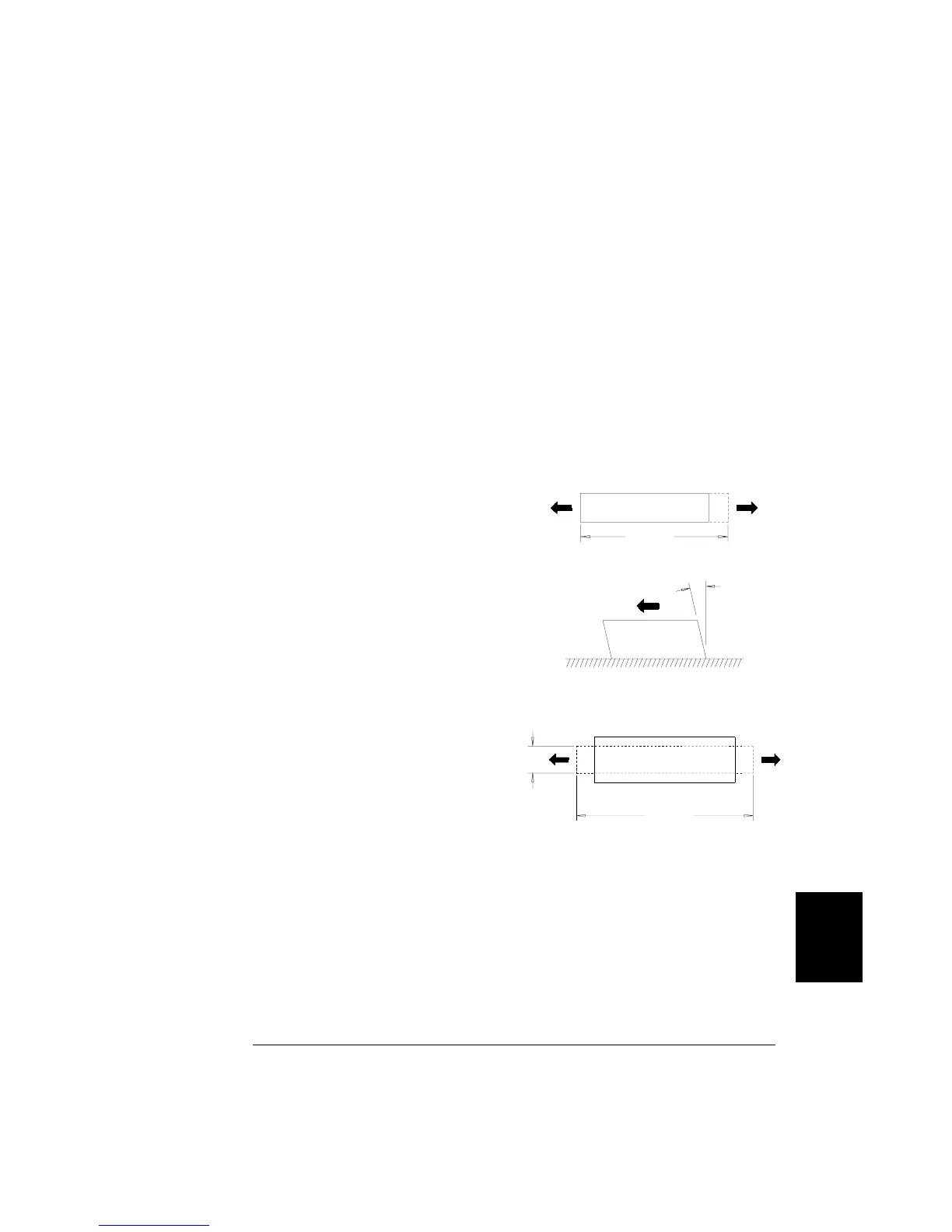

Normal Strain (

ε) is a measure

of the deformation along the axis

of the applied force.

ε = ∆L / L

Shearing Strain (

γ) is a measure

of the angular distortion of a

body. It is approximated by the

tangent of the angle formed by

the angular change between two

line segments that were parallel

in the undeformed state.

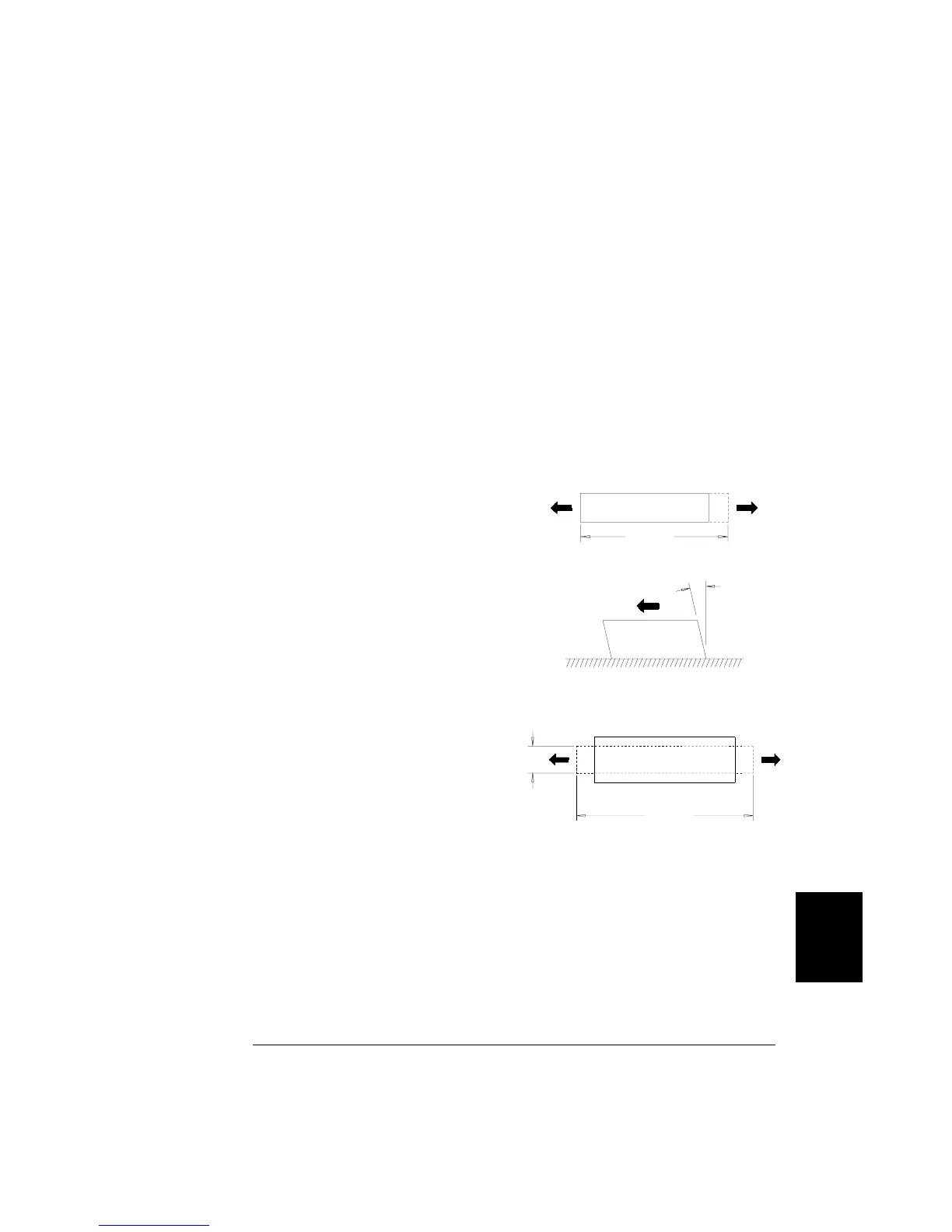

Poisson Strain (

ν) measures a

property of materials known as

the Poisson Ratio. It is the

negative ratio of transverse and

longitudinal normal strain

when a body has a longitudinal

tensile force applied.

ν = -ε

t

/ ε,

where ε

t

= ∆D / D and ε = ∆L / L

FF

L + ∆L

D -

∆D

Force

(F)

L + ∆L

Force

(F)

γ

F

8

Chapter 8 Tutorial

Measurement Fundamentals

373

Loading...

Loading...