2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 8 of 18

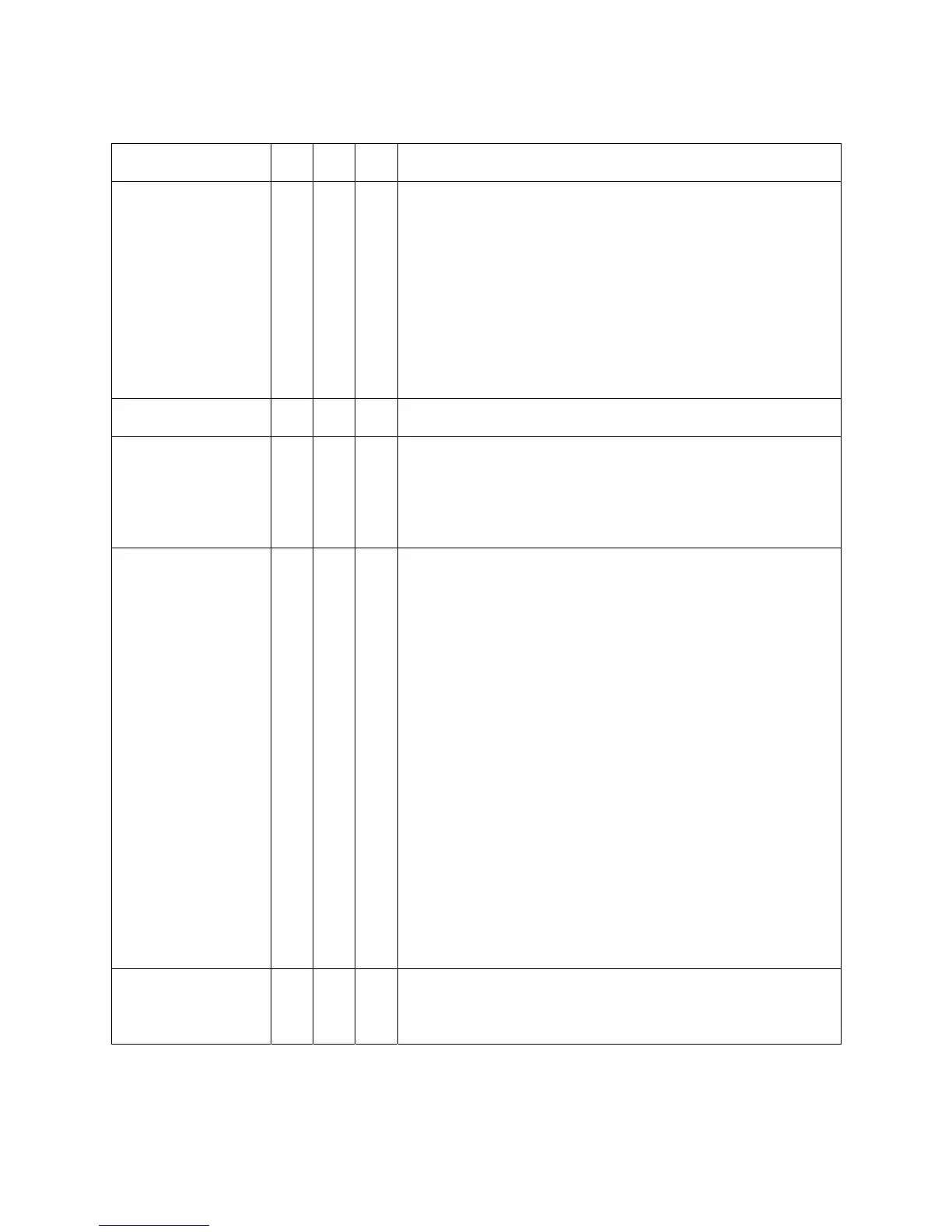

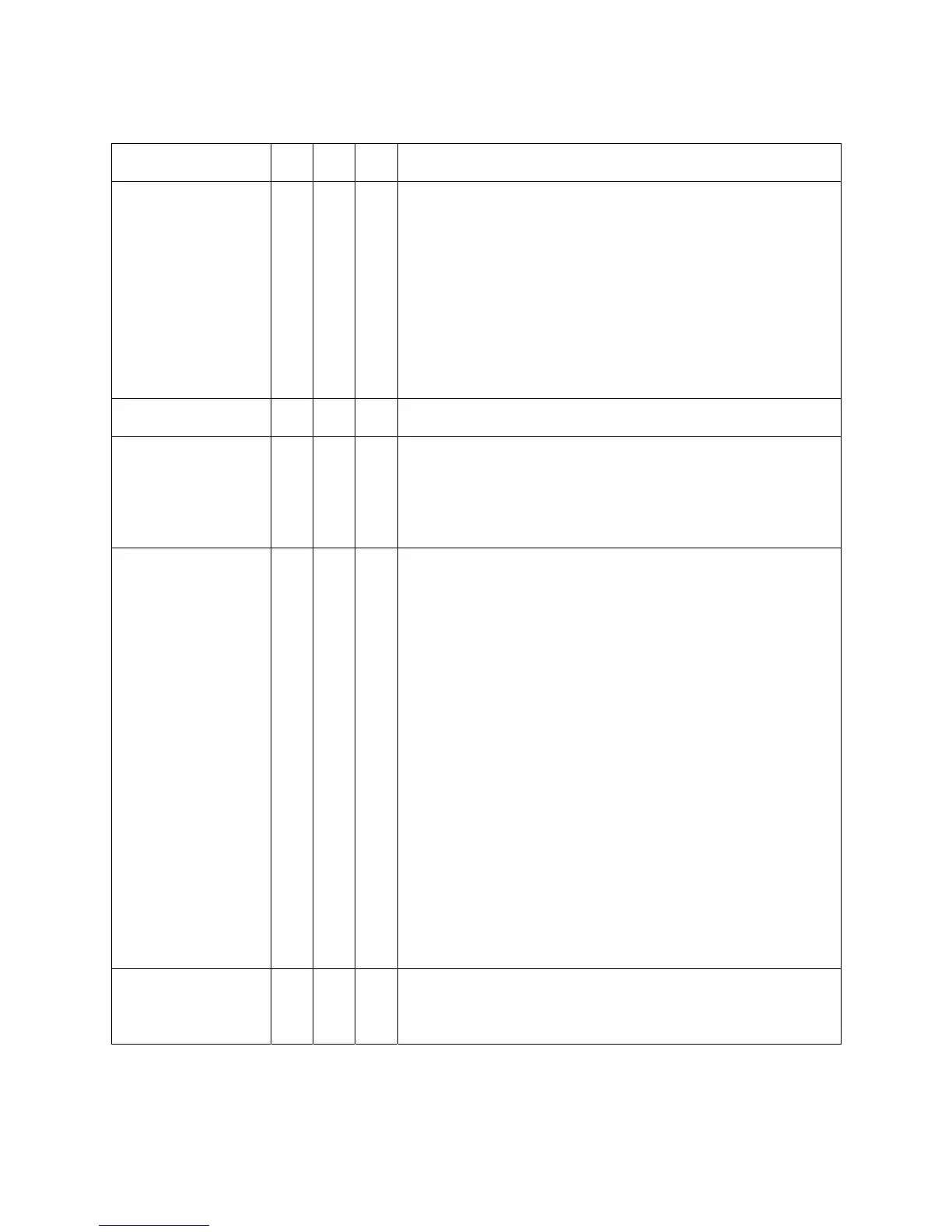

Quick check maintenance table

Component Mo 2M X Procedure

General inspection

9

9

9

9

Check for external dirt, leakage and signs of improper

maintenance. Initiate a service call if there is a leakage problem.

Verify that daily and weekly operator routines have been

performed correctly. See the latest User Guide.

Verify that all lubrication points have been oiled and greased

properly. See the latest User Guide.

Inform your regional manager if the press is not properly

maintained.

Config save

9

Perform Config save to update the customer diskette.

Ink unit

9

9

9

Calibrate the density sensors.

Calibrate the ink conductivity sensors.

Calibrate the ink flow rate.

ITM drum

9

9

9

9

9

9

9

9

Clean ITM slip ring (the bias contacts path) using IPA.

Clean the ITM thermostat slip ring.

Verify the temperature sensor reading, and calibrate, if required.

Make sure that the surface facing the IR sensor is clean.

Inspect and thoroughly clean the ITM hood wire mesh filter on

the rear wall using IPA soaked cloth. Caution: Shut down the

press before removing the mesh.

Check the bias carbon brush on the rear wall, and replace, if

required.

Check the ITM overheat thermal fuse carbon brushes on the

front wall, and replace, if required.

Make sure that the housing did not come loose from the press

wall.

Note: See Conditional replacement on page 12.

PIP drum

9

9

Check the grounding brush, and replace, if required.

Check the condition of the SofSub (PIP underlayer).

Loading...

Loading...