Page 12 of 36 Pages

Bleeding the System at Senders

After bleeding system at each slave bleeder valve, each

sender must now be bled. A small amount of air will be

trapped at the high point in each sender head.

1. Refill reservoir if required (fill tank at this time to between

1/2 and 2/3 full), and leave about 100 psi on the pressure

gauge.

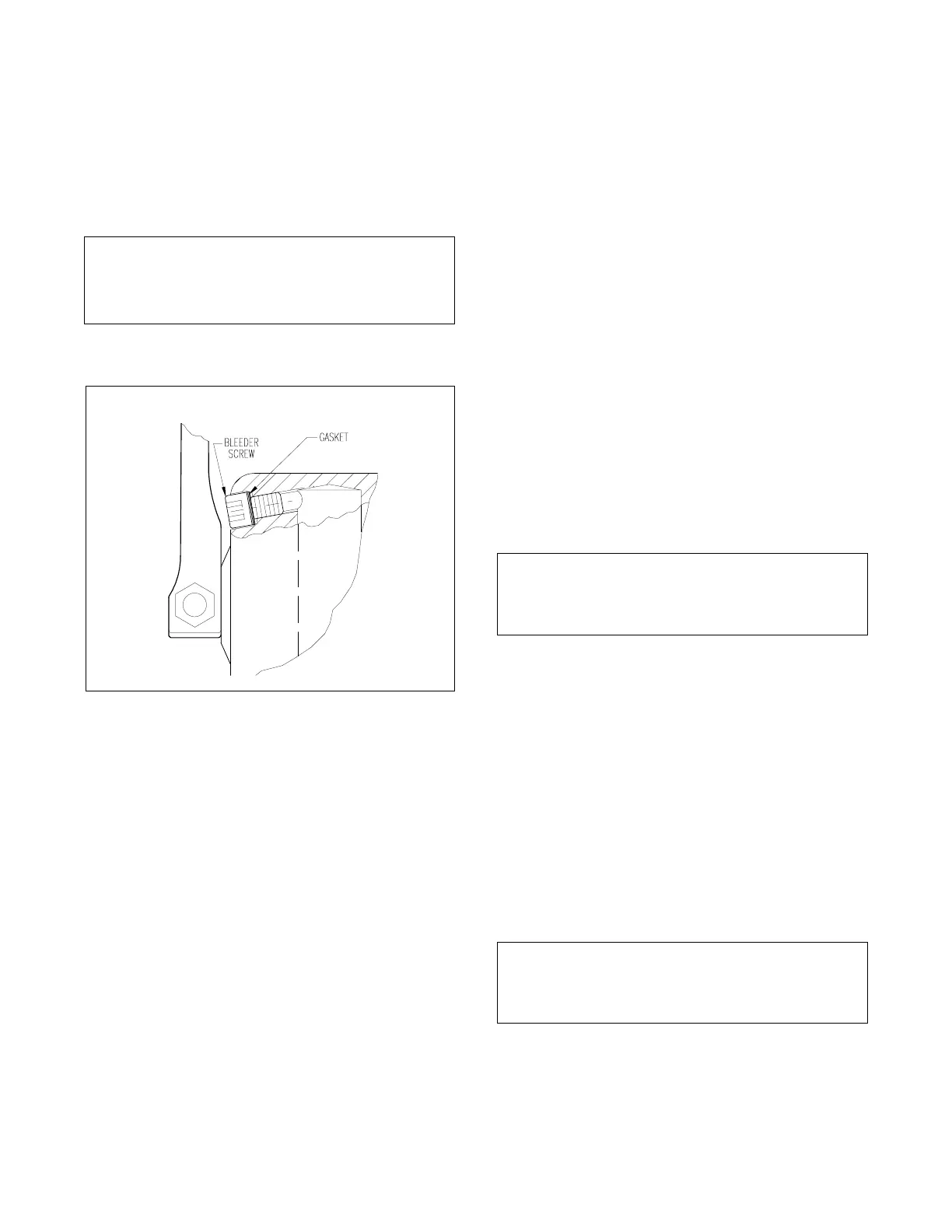

NOTE

Place a rag over the bleeder hole on the

sender, to prevent fluid from spilling on the

console.

2. Very slowly open the bleeder plug using a 3/16" allen

wrench. See Figure 10 for location of bleeder screw.

3. Allow the fluid to bleed out until the fluid is clear without air

bubbles.

4. Tighten the bleeder screw after bleeding.

5. Repeat Steps 1 to 4 above, for each sender.

6. The reservoir level should be between 1/2 and 2/3 full. If

the level is below this, the reservoir should be filled to this

level. Verify that pressurize in the reservoir is between

80 and 85 psi.

System Fluid

The fluid recommended for use in the system is a 50/50

mixture by volume of distilled water and ethylene glycol. The

type of ethylene glycol used is very important for proper

operation of your system and especially the synchronization

(charging) valve. Some additives, especially silicone addi-

tives, are very thick in consistency and will clog the elements

in the synchronization valve. If this occurs your system will

be unable to maintain synchronization between sender and

slave.

The ethylene glycol chosen for use should be as pure (no

additives) as possible, proportionately mixed with distilled

water then filtered to assure its purity. NEVER USE STOP-

LEAK TYPE ANTI-FREEZE.

Filtration is accomplished by passing the fluid through a 5

micron filter before using in the system.

Field service pre-filtering can be accomplished by using a

“Mr. Coffee”or equivalent paper filter placed in a funnel and

then pouring the ethylene glycol solution through it.

One paper filter will filter approximately 1/2 gallon ` of

ethylene glycol solution.

The MCO-03 fluid provided by Morse is proportionately

mixed and filtered to assure its purity and is ready for use.

Making the System Operational

Synchronizing the Controls

The system is now operational except for synchronizing the

controls.

1. Go to one control station and move each sender’s arm

from stop to stop, 3 to 5 complete cycles. Each sender should

be synchronized at this time.

NOTE

This synchronization can be performed at any

of the control stations.

2. If the position of the sender’s handle requires an awkward

motion by the user, adjust the handle by loosening the set

screw (using a 1/4" allen wrench) and rotating the handle so

that the user has more of a direct push-pull motion. Do not

position handle so that it binds against the sender body at

either end of its stroke.

3. Should one of the controls not come into synchronization,

go to that station which is out of synchronization and perform

Step 1.

Connecting Engine Controls

1. Connect throttle linkages to the throttle slave. Repeat for

both engines.

2. Connect clutch linkages to the clutch slave. Repeat for

both engines.

NOTE

For any operational problems at this point,

consult the trouble shooting section.

Operation

Throttle Senders

Forward Motion — Increases Throttle.

Aft Motion — Decreases Throttle.

Figure 14. Bleeder Screw

Loading...

Loading...