Page 10 of 36 Pages

Rules for Routing Tubing

NOTE

The instructions and illustrations in this section

apply to nylon tubing ONLY. Information on

use of Copper Tubing may be found on page 12.

1. Keep tubing free of dirt and foreign matter.

2. Keep tubing away from batteries, since battery acid is

corrosive to the tubing.

3. Tie the tubing down at regular intervals using non-metallic

ties and clamps.

4. Do not allow tubing to become kinked. If it does, replace

that particular run of tubing.

5. String tubing so that it will not interfere with hatchways or

machinery removal.

6. Use only nylon tubing supplied with system from Morse.

Assemble tubing connectors on every tube end as described

and illustrated in Figure 13.

NOTE

The roll of tubing should be laid in a horizontal po-

sition and moved as little as possible to avoid

kinking and tangling.

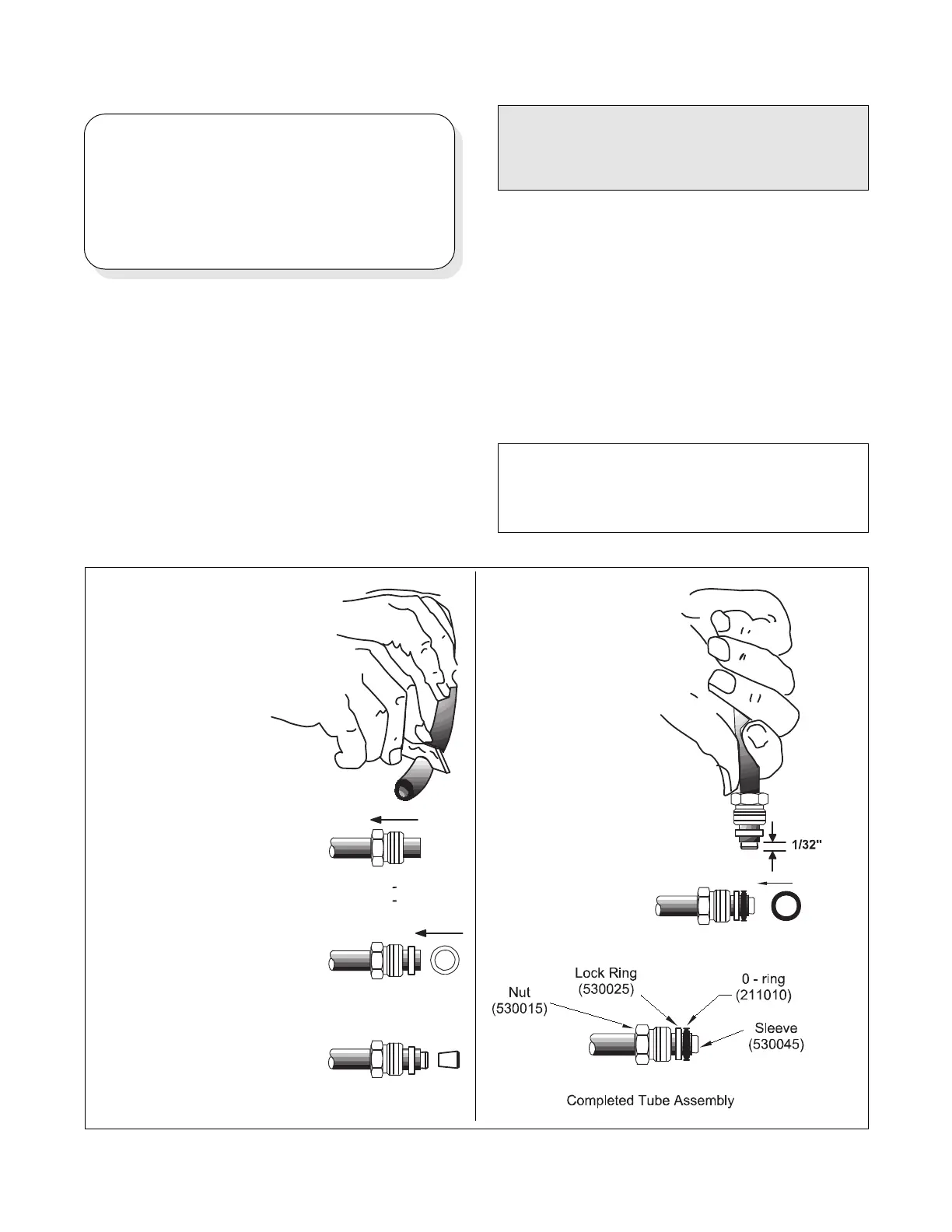

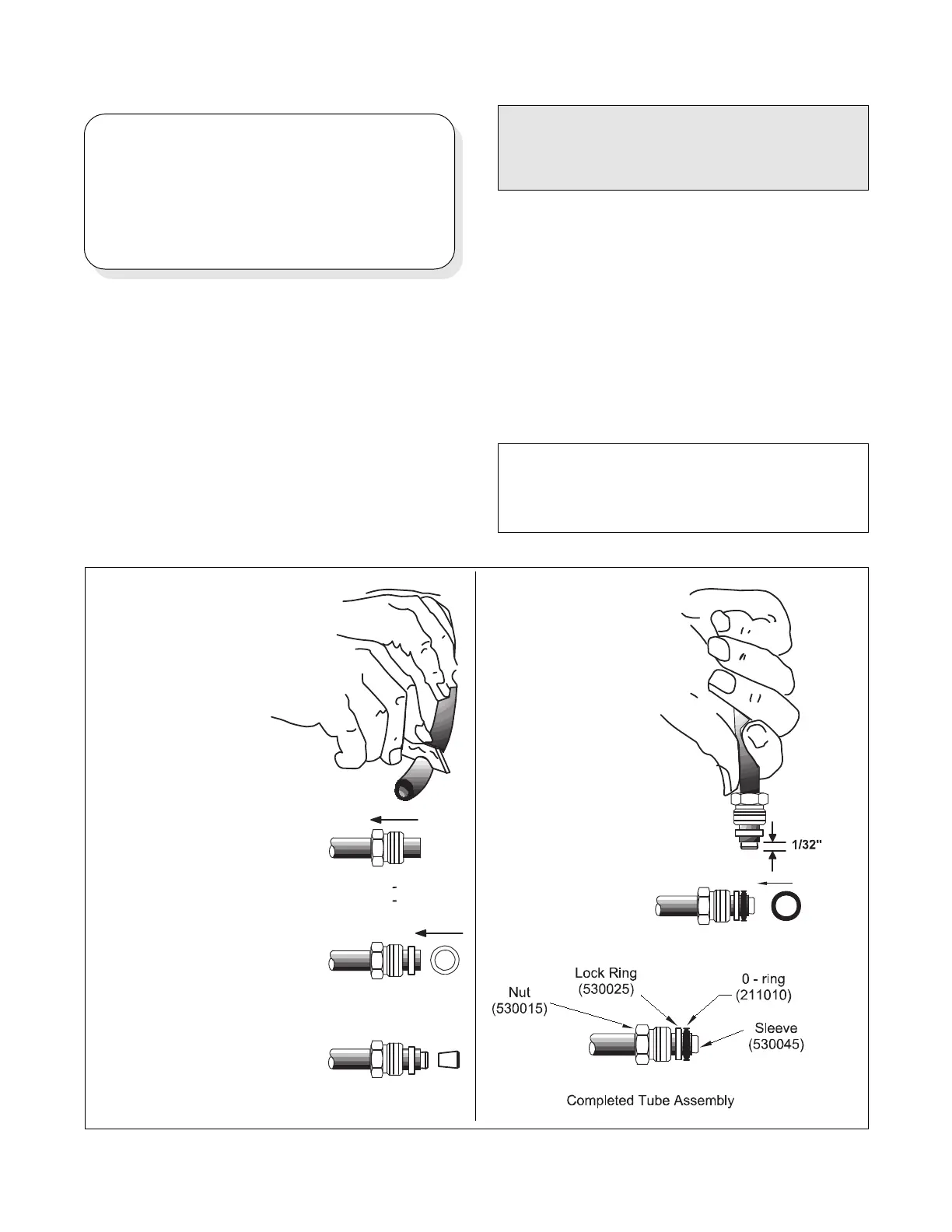

4. Insert the sleeve (530045)

in the tube until it just makes

contact all around.

3. Push the lock ring

(530025) over the end of the

tubing and move it back at

least one sleeve length from

the end. The lock ring may

slide on freely or require

slight pressure and "screw-

on" action. (The lock ring

has a left hand thread.)

6. Install the 0-ring (211010)

over the end of the tubing

and against the lock ring

(530025).

CAUTION

Dirt and foreign matter in the hydraulic

system cause damage and malfunction. It

is extremely important to keep tubing and

fittings clean when installing and connect-

ing components. Cut tube cleanly and

tape the open end while running tubing.

Four tubing installation plans are provided in the Tubing

Diagrams Section later in this manual:

1. Twin Engine, One Station, (Plan I)

2. Twin Engine, Two Station, (Plan II)

3. Twin Engine, Three Station, (Plan III)

4. Twin Engine, Four Station, (Plan IV)

Before beginning to run the tubing, it is recommended that

each tube be assigned a number which is marked on both

ends, and correspondingly, marked at the origin and desti-

nation of that tube. These designations should also be

recorded on the chosen plan diagram for future reference.

Figure 13. Assembling Tubing Connectors

1. Cut the tubing with a ra-

zor or very sharp knife, leav-

ing the cutoff end as square

as possible.

2. Slip the nut (530015) over

the tubing end. The nut

should slide freely.

5. Force the sleeve (530045)

into the end of the tubing by

pushing it against a clean,

flat surface. Thread the lock

ring (530025) toward the end

of the tube as far as pos-

sible by hand. Leave suffi-

cient room between the lock

ring and the end of the

tube to install theO-ring

(211010).

Tubing Installation and Connection

Loading...

Loading...