Page 8 of 36 Pages

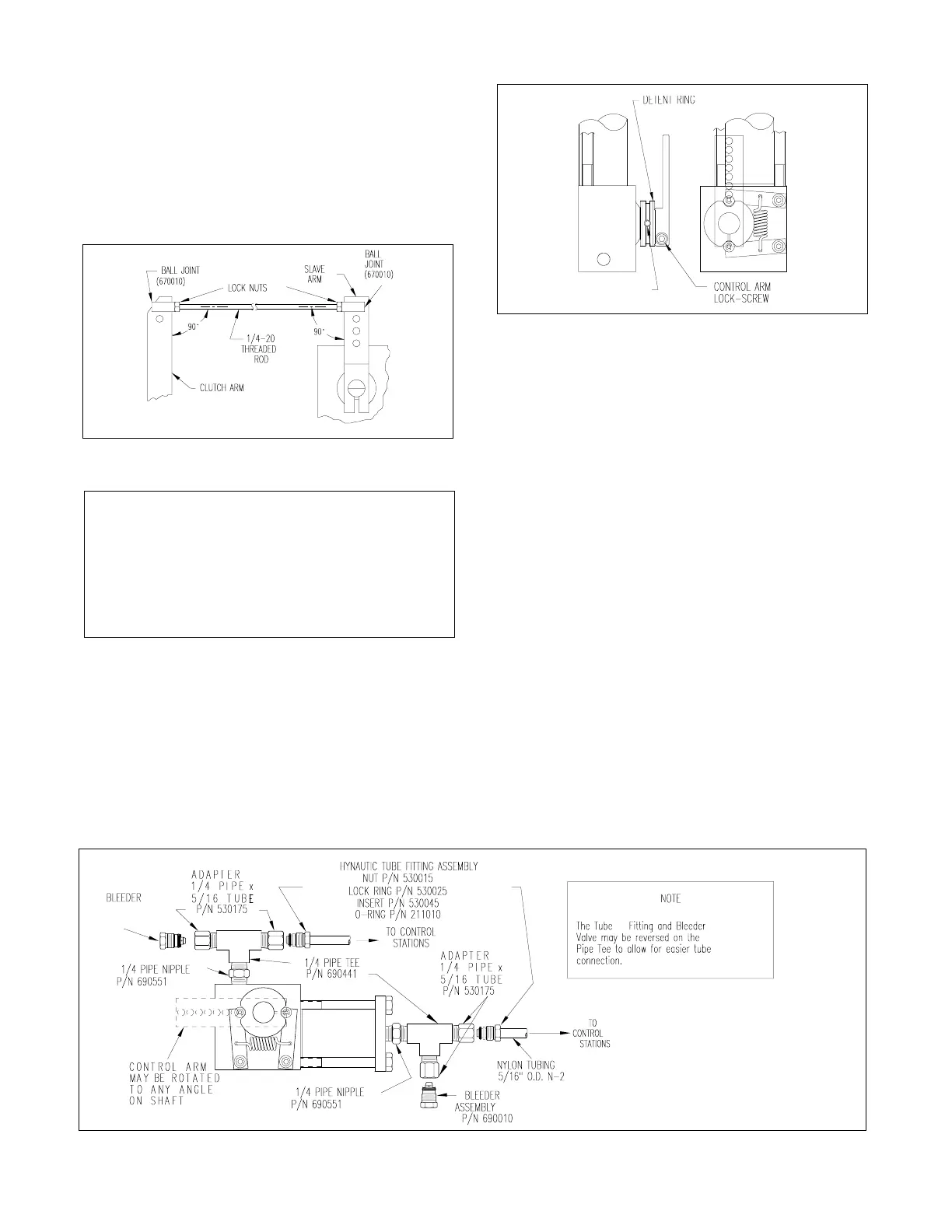

Figure 9. SS-04 Shifter Slave - Bleeder Valve and Tubing Adapters Installation

5. Secure detent ring in this position by tightening the set

screw.

6. Install a lock nut and ball joint on the end of the 1/4-20

stainless steel or brass threaded rod.

7. Position the clutch slave to its mid-stroke and connect the

ball joint end of the 1/4-20 threaded rod to it.

8. Position the engine’s clutch arm to neutral, determine the

proper length of the threaded rod required and cut off the

excess.

9. Install a lock nut and ball joint on the other end of the

threaded rod.

10. By locating the slave arm ball-joint in its proper hole and

adjusting both ball joint on the threaded rod, find the correct

length of linkage that will allow both "full- forward" and "full-

reverse" on the transmission for full throw on the clutch slave

arm.

11. After determining the correct linkage length, securely

lock the ball-joints to the threaded rod with lock-nuts pro-

vided. Disconnect the linkage from the clutch slave’s arm.

12. Locate and secure in place two tees, two bleeder valves,

and two tubing adapters, per Figure 9.

13. Repeat this clutch slave installation procedure for the

second engine.

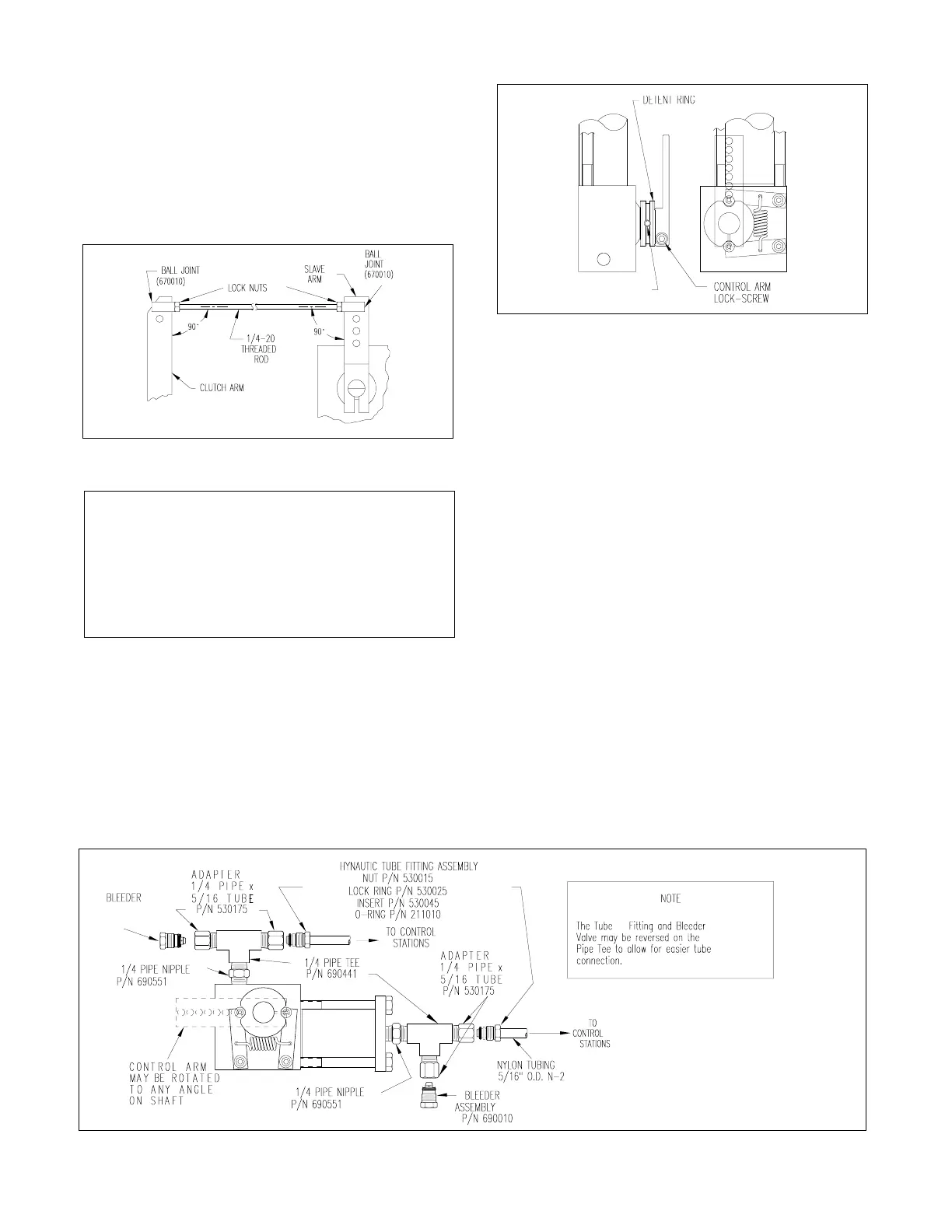

Figure 7. Proper Clutch Slave to Throttle Arm

Installation

Clutch Slave Installation

The Morse clutch slave must be mounted so that when the

engine’s transmission is in neutral and the Morse clutch

slave’s arm is at its mid-stroke, both arms will be: 1) in the

same plane; 2) parallel to each other; and 3) right angles will

be formed between connecting linkage and each arm, see

Figure 7.

NOTE

The clutch slave’s arm may be set to any

desired position by loosening the tightening

screw (using a 3/16" allen wrench) in the lower

end of the arm. Rotate arm as desired and

reset the screw. After the arm is set it will have

a 78° maximum arc.

1. Secure mounting bracket to the engine. A suitable bracket

must be fabricated.

2. Secure the transmission slave to the mounting bracket

using the 3/8-16 mounting bolts.

3. Set the transmission in the neutral position, and the clutch

slave’s arm at its mid-stroke.

4. Loosen the set screw in the detent ring on the clutch slave

and rotate the detent ring to the full detent position. To locate

the detent ring, see Figure 8.

Figure 8. Detent Ring Location

▲

▲

Loading...

Loading...