Page 6 of 36 Pages

Steps 1 thru 8 apply to both ST-04 and ST-06 Systems

1. Secure the mounting bracket to the engine. A suitable

bracket must be fabricated.

2. Secure the throttle slave to the mounting bracket using

3/8-16 mounting bolts.

3. Install a lock nut and bungee-ball joint on the end of a

1/4-20 stainless or brass threaded rod.

4. Position the throttle slave to its mid-stroke and connect the

bungee end of the 1/4-20 threaded rod to it.

5. Position the engine’s throttle arm to its mid-stroke. Deter-

mine the length of threaded rod required and cut off the

excess.

6. Connect a lock nut and a ball-joint to the engine’s throttle

arm and the free end of the threaded rod.

7. Find the proper hole in the slave arm to provide a linkage

length combination that will allow idle to full throttle on the

engine, using all but a few degrees of slave arm travel in each

direction. By adjusting the ball-joint and bungee, a fine

adjustment in both directions can be achieved. Be sure the

slave arm can over-travel through the bungee to the end of

its stroke in each direction.

8. After determining the correct rod length, securely lock the

ball-joint and bungee assembly to the threaded rod with lock

nuts provided. Disconnect the linkage from the throttle slave’s

arm.

ST-06 Installation Only

9. To prevent engine retard due to governor spring or

vibration, a pilot check valve is built into the ST-06 Throttle

Slave.

NOTE

This built-in valve will lock the slave arm in place

allowing it to be moved only by the sender

10. Locate a tee and bleeder valve on the throttle slave and

install suitable adapters to accept tubing, per Figure 5.

NOTE

Tube connectors are installed on the tubing

per instructions under “Tubing Installation”

and “Connection” on page 8.

11. Verify all fittings installed have been tightened. Repeat

these throttle slave installation procedures for the second

engine.

Throttle Slave Installation

NOTE

The standard Teleflex Morse System,

MC-04, uses the ST-06 Integrated Throttle

Slave. You may have chosen to order a

non-standard system which includes the

ST-04 Throttle Slave and STV-10 Lock-out

Valve. Depending on which system you

have, follow the corresponding installa-

tion instructions in this section.

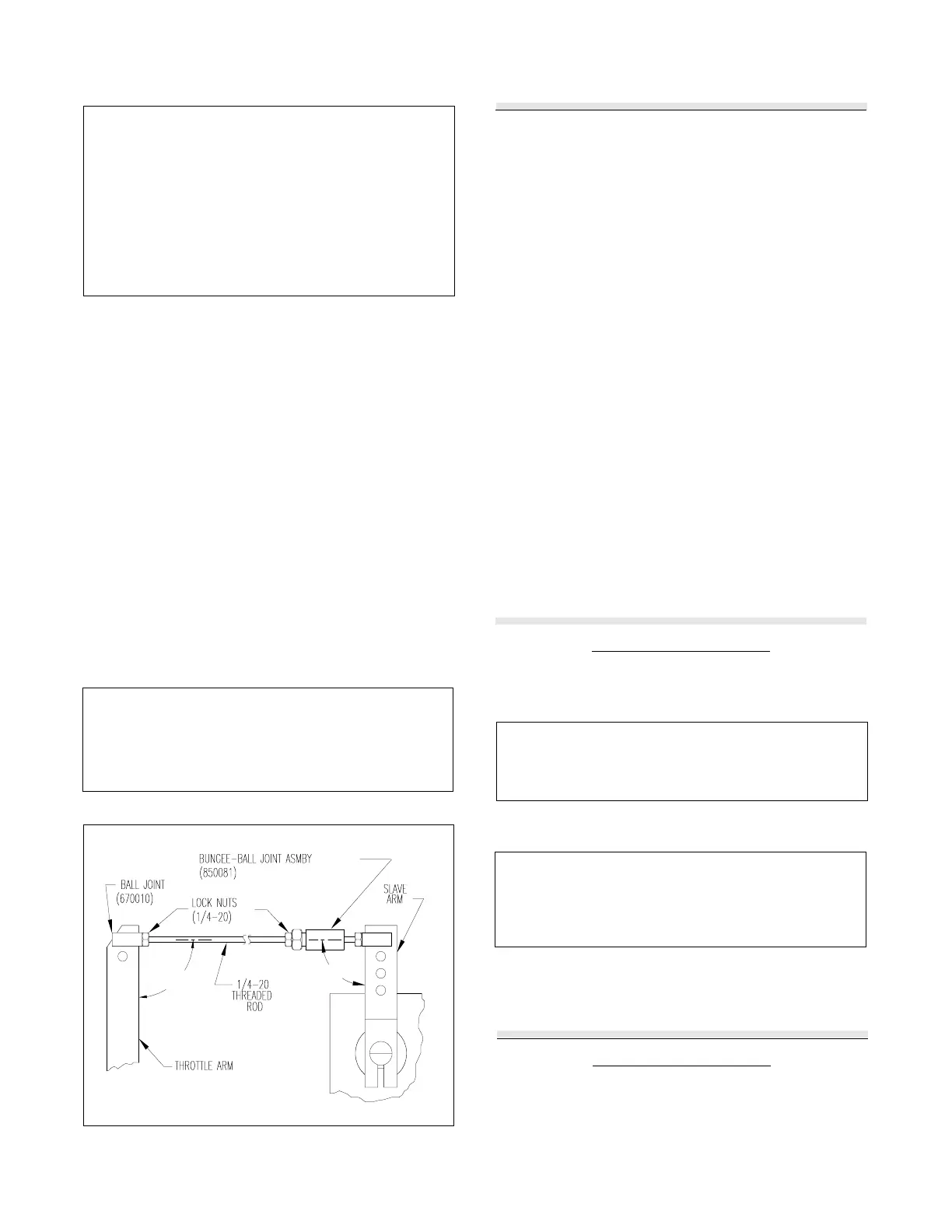

Figure 4. Throttle Slave to ThrottleArm Installation

ST-04 Installation Only

9. To prevent engine retard due to governor spring or

vibration, a separate STV-10 lock-out valve is used with the

ST-04 Throttle Slave.

Teleflex Morse throttle slaves must be mounted so that at the

mid-stroke of both the engine’s throttle arm and the slave’s

control arm, they are: 1) In the same plane; 2) parallel to each

other; and 3) right angles will be formed between the con-

necting linkage and each arm. See Figure 4.

If these criteria are met, an ideal installation will result.

A spring bungee-ball joint assembly is furnished with each

throttle slave. It is installed in the slave arm-to- throttle

linkage according to Figure 4. It allows up to 3/16" slave

arm over-travel in each direction. This over-travel lets the

slave cylinder travel its full stroke and still provide full travel

to the throttle arm. You must use almost all of the slave travel,

or about 75°, to operate the throttle. The slave must go full

stroke in each direction in order to synchronize the system.

The throttle slave’s arm may be set to any desired position by

loosening the tightening screw (using a 3/16" allen wrench)

in the lower end of the arm and then rotating the arm as

desired and resetting the screw. After the arm is set, it will

have a 78° maximum arc.

CAUTION

The Throttle Slave must not be mounted to

any surface exceeding 220° F (103° C). If

mounting in a "hot spot" is unavoidable, the

slave must be insulated from the heat.

Loading...

Loading...