7.2 Intensifier

Special Tools

In addition to any standard tools, the following special tools are required:

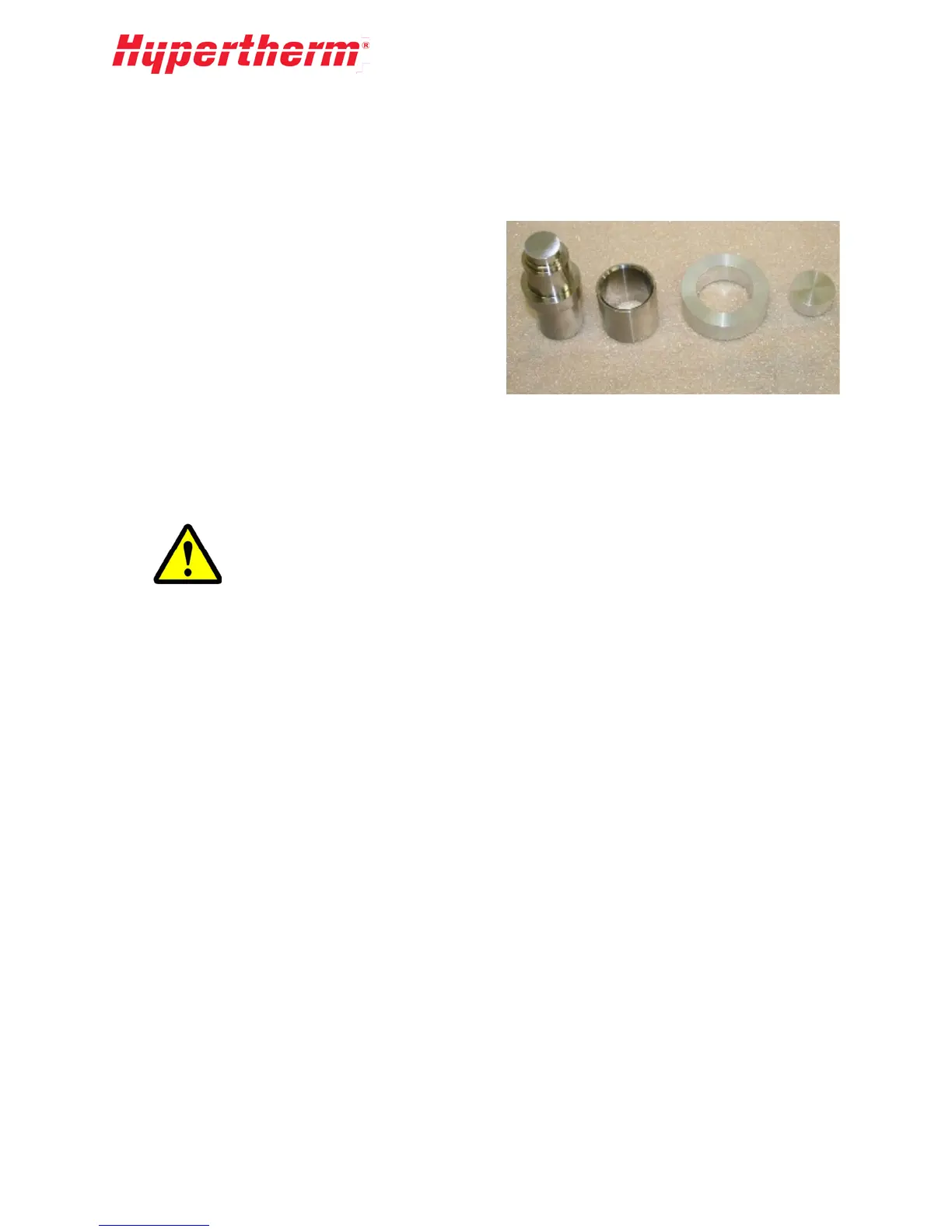

• 11557 Seal Insertion Tool Assembly (Includes:

11812 Push Tool, 11811 Sleeve Guide, 11550

Locating Ring, 12932 Spacer Tool)

• 11985 Seal Housing Removal Tool

• 300 ft-lb torque wrench with 3/4 in. square drive

• 1-1/2 Hex x 3/4 in. Square Drive Socket

• 3/4 in. Hex x 3/4 in. Deep Square Drive Socket

• 3/4 x 13-1/2 in. Hex Driver

• High Pressure Food Grade (H1) Lubricant

Due to the high forces inside the intensifier all bolts and cap screws that fasten the load carrying

components are Grade 8. Fasteners that are exposed to cyclic loading use lock washers. Torque the load

carrying fasteners to the correct Torque Specifications unless otherwise noted.

Keep all interior parts and surfaces clean. All parts should be placed on clean

work surfaces. When changing HP components such as HP seals, hands should

be washed and kept clean. Before reassembling any high pressure or hydraulic

components, verify that the components have been wiped clean to remove any

dirt or other contaminants.

7.3 High-Pressure Ends

High-Pressure Seal Replacement

Replacing the high-pressure seals and hoops is the most common service function. Water dripping from

either end of the HP cylinder indicates that the seals may soon require changing. One drip every few

strokes means that the seals should be watched. More than one drip with each stroke means that the

seals in that HP cylinder should be changed at the first opportunity.

This section will provide the basic information needed do in-house replacements and service on the

high-pressure ends for the HyPrecision 100D/150D pumps. For any questions and all other service

needs please contact 0.15"service representative.

The high-pressure end drawing shows the locations of the components and their part numbers. Always

check the part list included with this manual for the latest parts and their replacement part numbers.

38

Loading...

Loading...