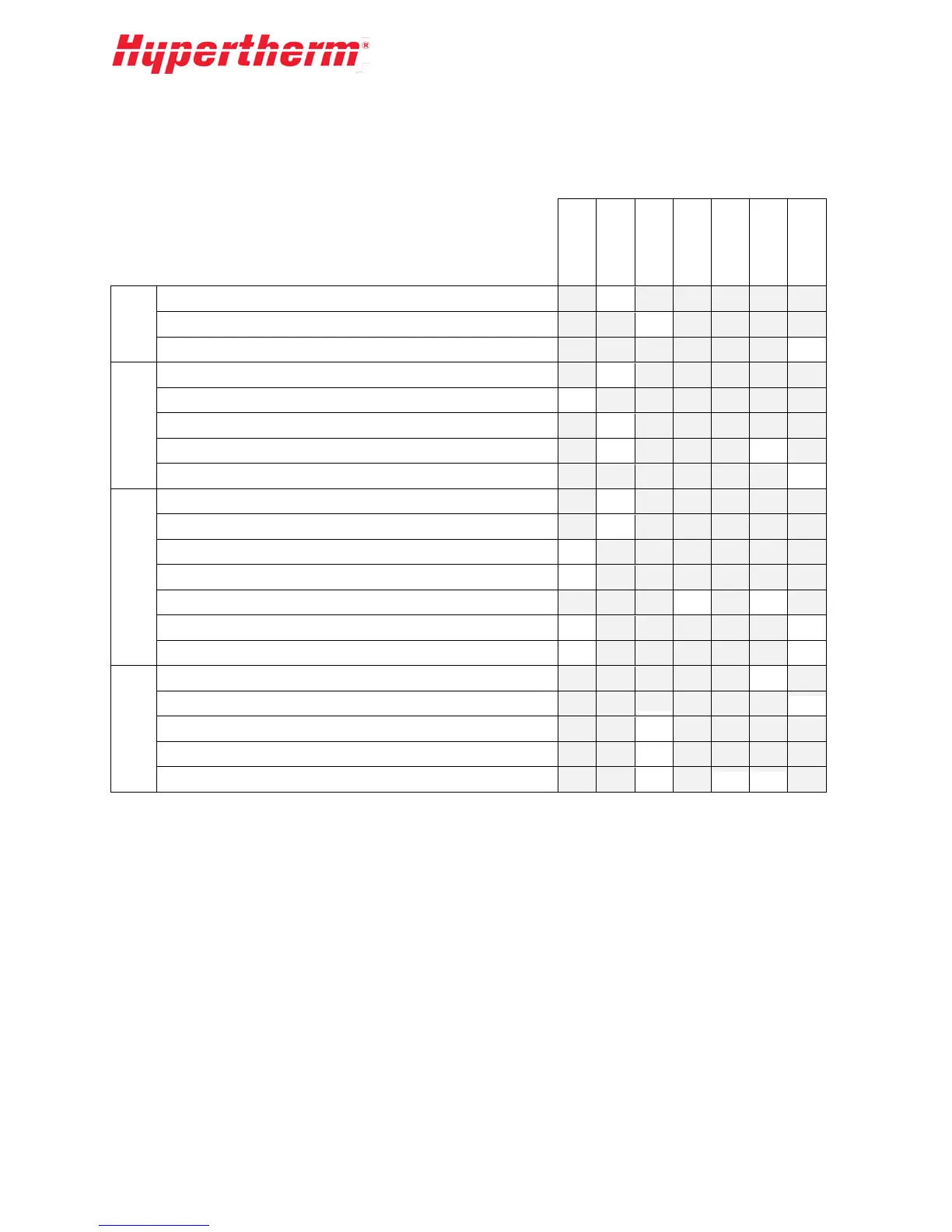

Scheduled Maintenance Chart

The following maintenance intervals are based on 4,000 hour per year operation. Less hours of use will

increase maintenance interval length.

As required

Per shift

Weekly

Monthly

3 months

6 months

Yearly

Electrical

System

Inspect all cables and plugs for damage

I

Check safety circuits

I

Grease motor bearings

Low Pressure

Water

Inspect fittings and hose for damage

Adjust cooling water flow

A

Check inlet water pressure

Inlet water filters

R

Check pressure in water accumulator – set to 40 psi

I

High Pressure

Water

Visually inspect for leaks

Check temperature of intensifier and bleed down valve

Lap or replace LP poppet and check valve face

R

Replace HP seals

R

Replace HP filter at pump outlet

Replace hydraulic rod seal

I

Replace plunger bearing

I

Hydraulics

Change oil filter (sooner if bypass occurs)

Change oil

Check oil level

I

Check oil temperature

Check for oil leaks

A – Adjust I – Inspect R – Replace

64

R

Loading...

Loading...