Preventive Maintenance Program

28 809490 Instruction Manual XPR

Cutting area and operation effects

The component replacement schedule is for reference only. Your cutting area conditions and

operations can have an effect on your component replacement schedule.

These topics give the most common conditions and operations that increase the wear on some

components in your plasma system. This wear decreases system performance and component life.

If any of these conditions or operations apply, change your replacement schedule as suggested.

How much you need to change your schedule depends on how bad the condition is. If you have

questions about your replacement schedule, contact your OEM or regional Hypertherm Technical

Service team.

External cutting area

Consumables and torch assemblies stored in dirty cutting areas with no protection can collect

contamination, such as dirt and metal dust. If this contamination gets into the torch or coolant, it can

cause the following problems:

Prevent O-rings and seals on the torch heads and receptacles from sealing

Increase wear on torch heads and receptacles

Increase wear on the coolant pump

Cause unsatisfactory operation of the coolant flow switch

It can help to flush the coolant system or clean the flow switch. But, it can

be necessary to replace the coolant switch to fully repair the operation of

the coolant loop system.

The best solution is to store consumables and torch assemblies in a clean, protective space.

Another solution is to use compressed air to clean these parts before you use them.

If you cannot store your consumables and torch heads in a protective space, you can replace the

following components more frequently.

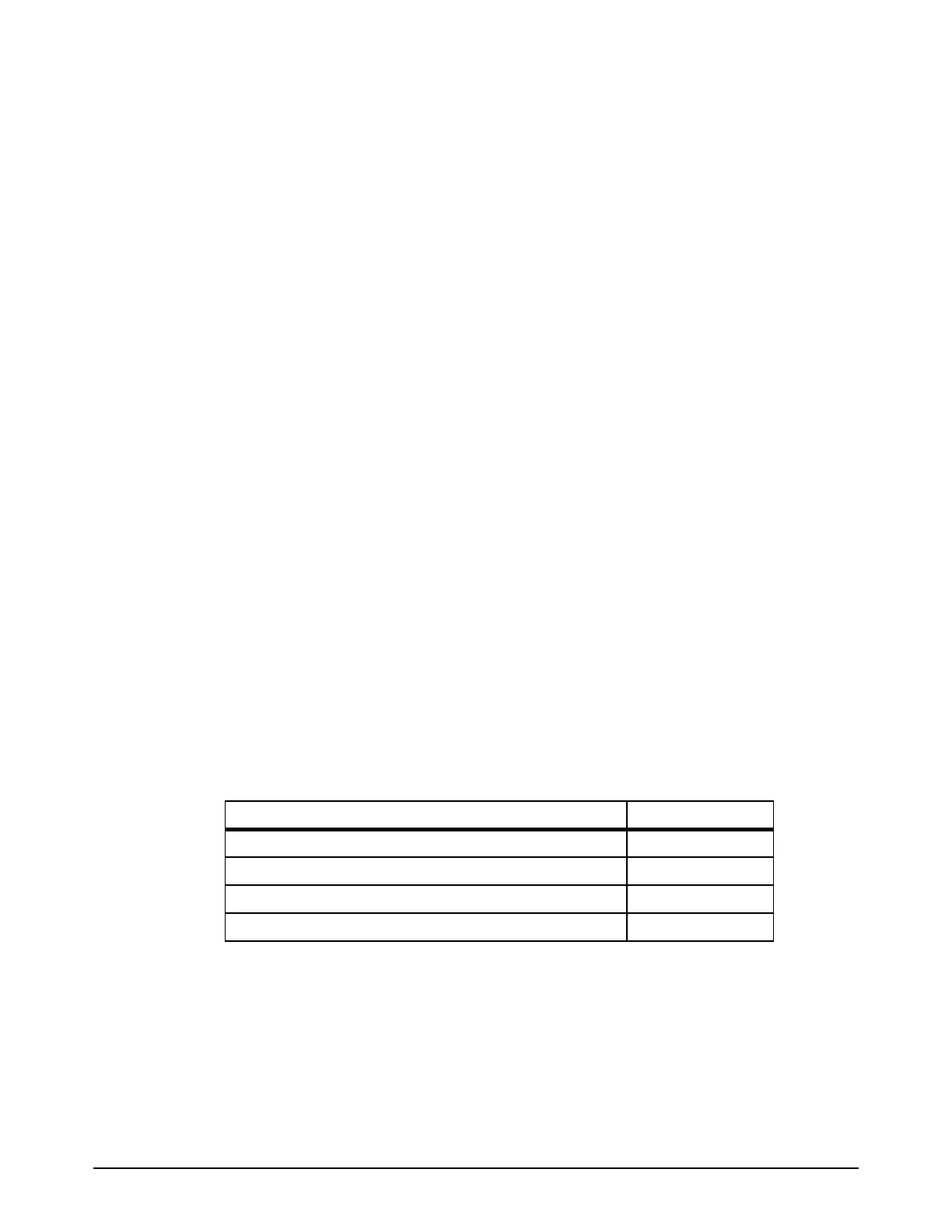

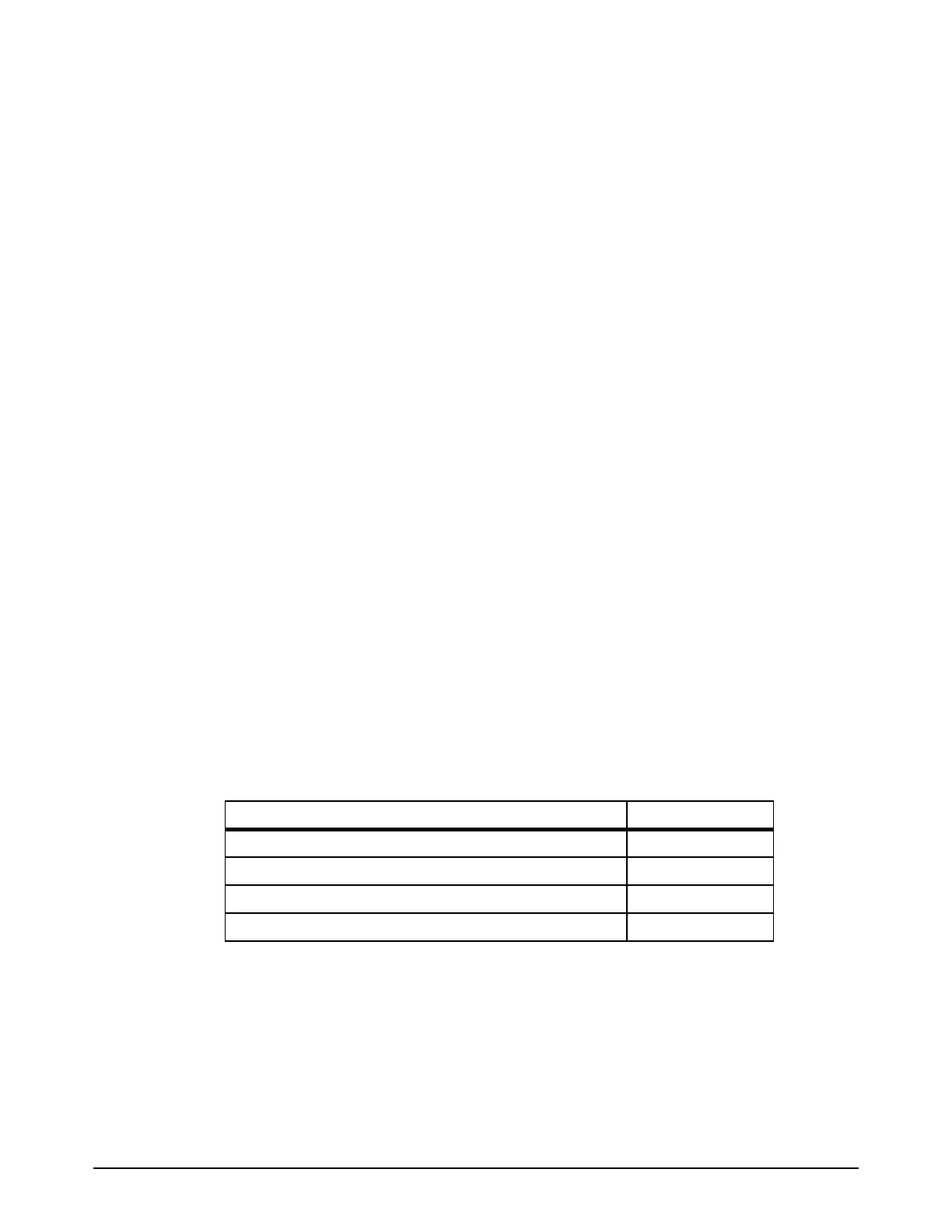

Description Part number

Quick-disconnect torch receptacle 420220

Quick-disconnect torch 420221

Kit: Coolant pump assembly 428729

Kit: Coolant flow meter 229741

Loading...

Loading...