Preventive Maintenance Program

XPR Instruction Manual 809480 29

Incoming air supply quality

To maintain system performance, it is important that the incoming air supply is clean. If the air supply

has dirt, oil, or water in it, components can become clogged or defective. An air supply of bad

quality can cause the following problems:

Decrease air flow

Increase system gas errors

Decrease cut quality and performance

Oil in the torch head can cause a fire when the oil reacts with the oxygen cutting process. Also,

unwanted material in pressure sensors can cause false pressure readings.

The best solution, if possible, is to improve the quality of the air supply. Contact your OEM or

regional Hypertherm Technical Service team if you need advice on how to improve the quality of

your air supply.

If you cannot change your air supply quality, you can replace the following components more

frequently.

Metal dust inside the power supply cabinet

Plasma cutting makes metal dust. If metal dust collects inside the plasma power supply, it can

decrease the life of the fans.

The main power supply, chopper, or heat exchanger fans can operate more slowly, or failure of the

fans can occur. This can cause temperature-related errors.

The best solution to extend the life of the fans is to clean inside the power supply. For instructions,

see Clean inside the plasma power supply on page 17.

If metal dust has collected inside your power supply, you can replace the following components

more frequently.

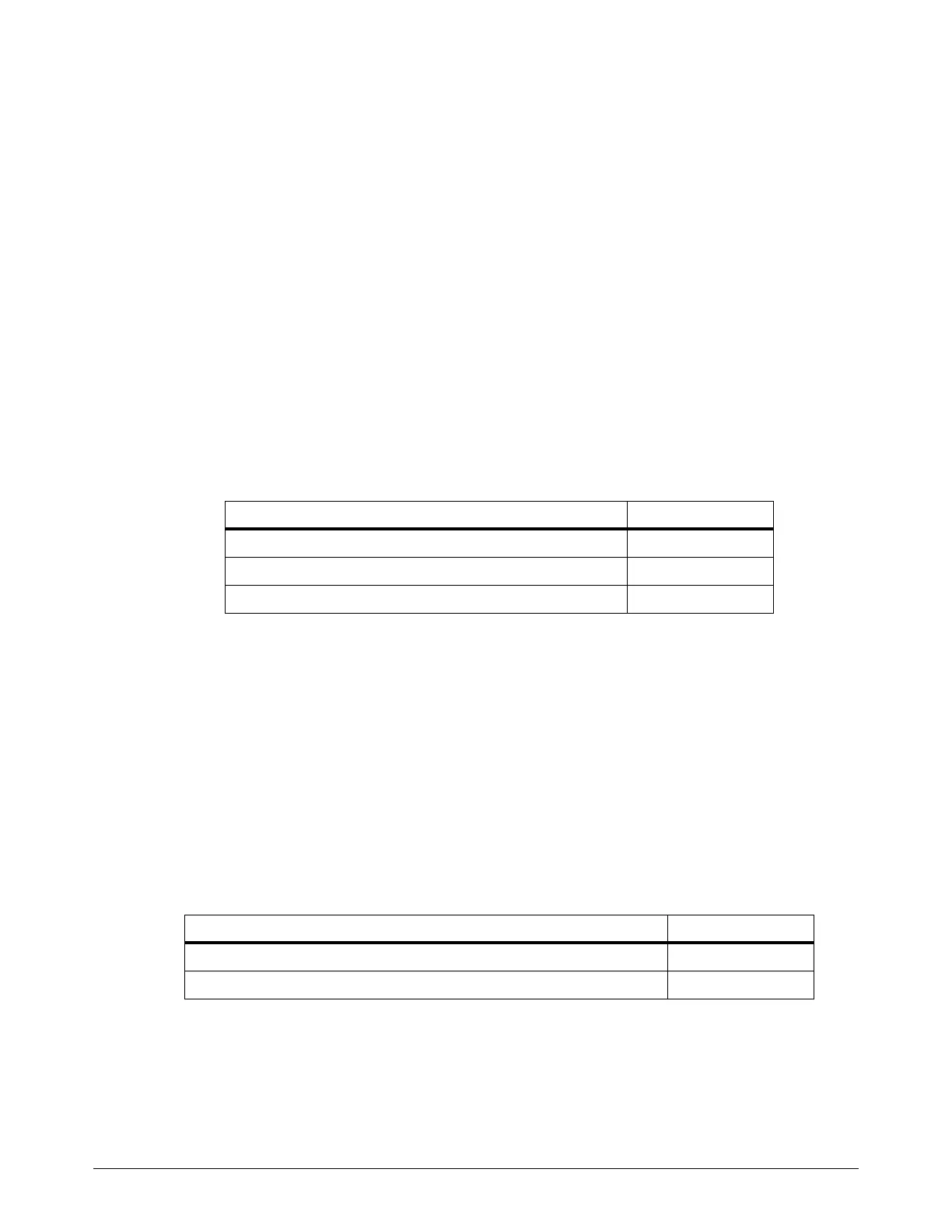

Description Part number

Air filter element 011110

Quick-disconnect torch 420221

Gas solenoid valve, pressure transducer –

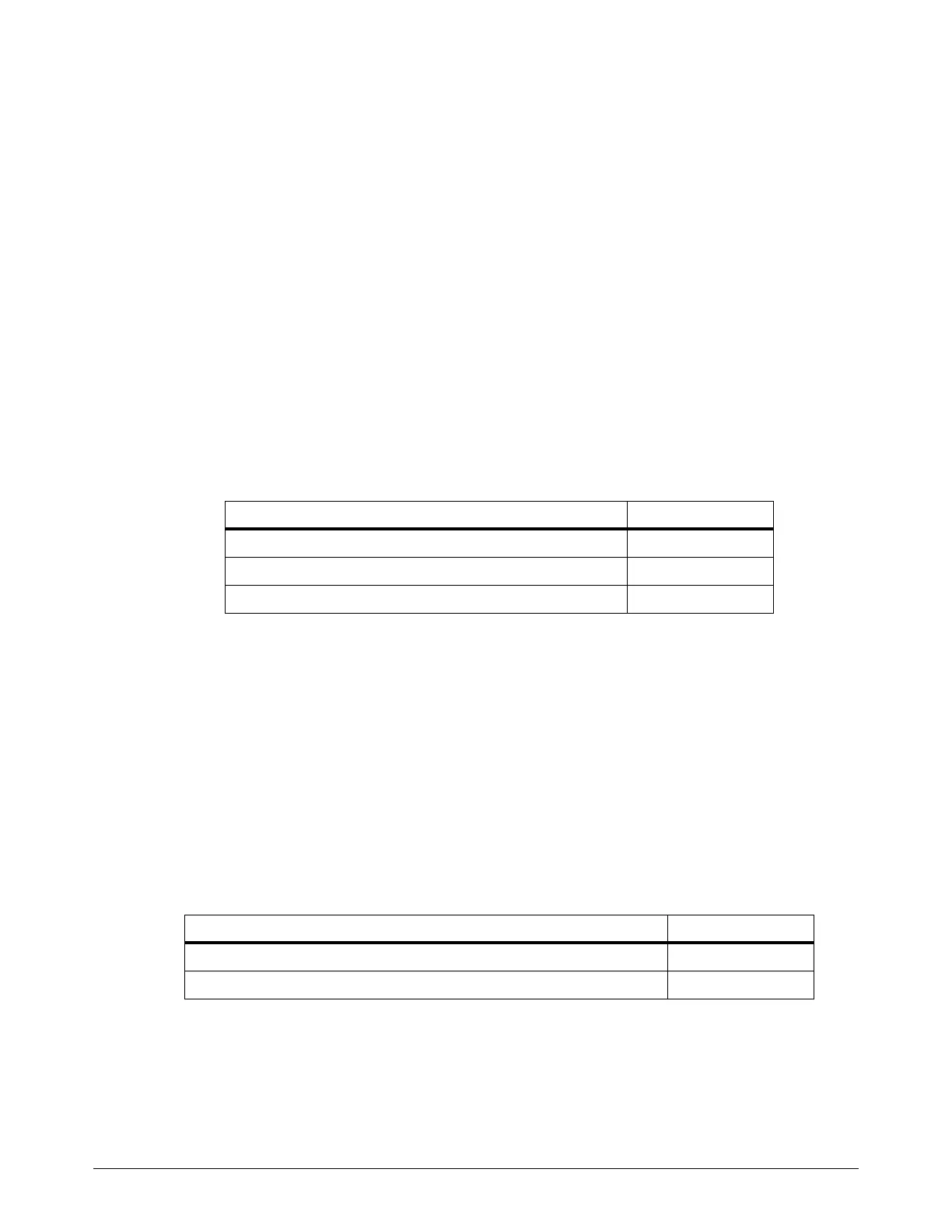

Description Part number

Fan assembly: 292 cfm, 48 VDC,120 mm (4.7 inch) diameter 229821

Fan assembly: 890 cfm, 48 VDC, 254 mm (10 inch) diameter 229822

Loading...

Loading...